Splitting the crankcase halves

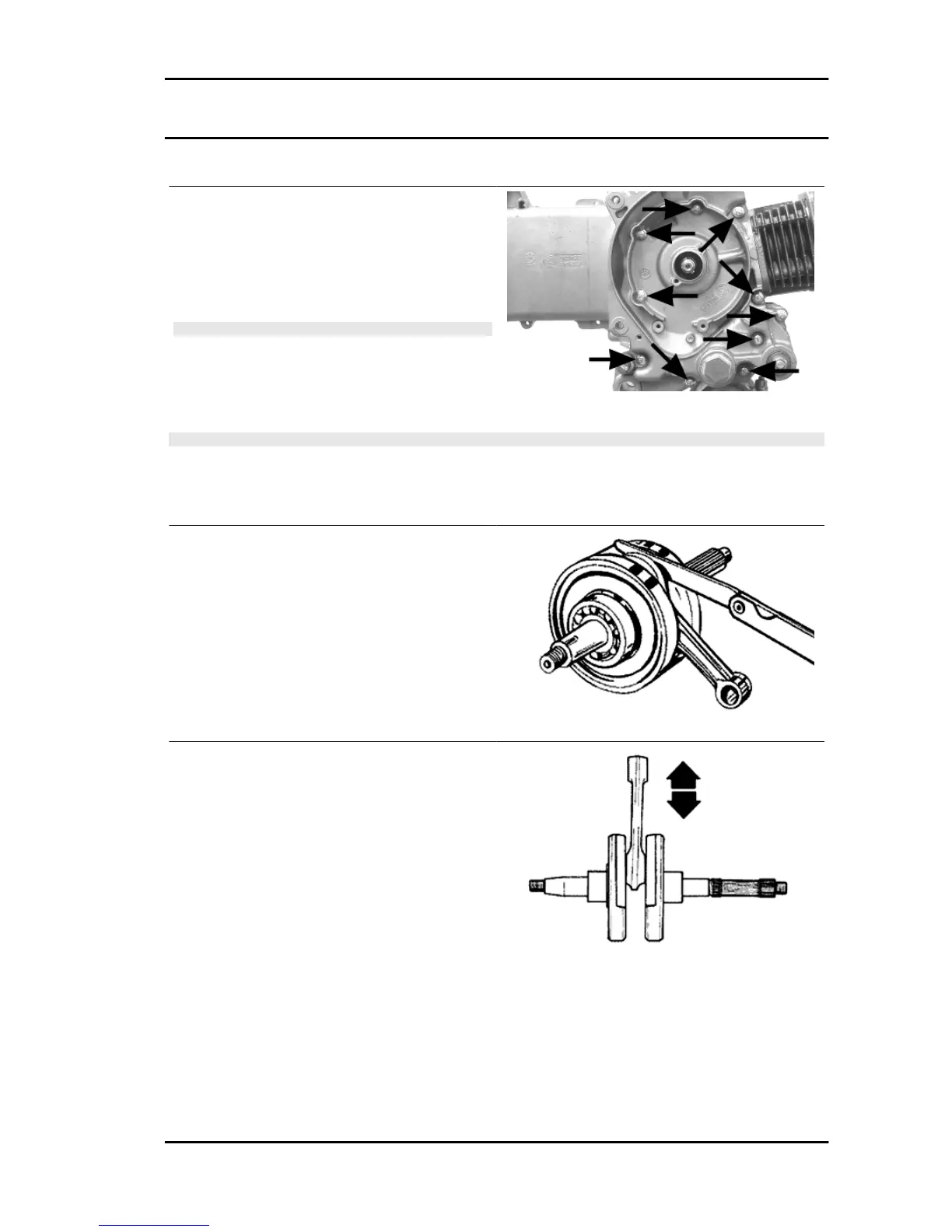

- Remove the ten crankshaft coupling screws.

-Separate the crankcase halves keeping the half

casing driving shaft engaged on the transmission

side.

- Remove the crankshaft.

CAUTION

IF YOU FAIL TO DO THIS, THE CRANKSHAFT MIGHT AC-

CIDENTALLY FALL.

- Remove the oil guard on the flywheel side.

CAUTION

THE CENTRIFUGAL OIL FILTER IS IN THE FLYWHEEL AXLE SHAFT. CONSEQUENTLY, DO NOT

WASH WITH SOLVENTS OR BLOW COMPRESSED AIR SO THAT NO IMPURITIES LEAK OUT. A

CENTRIFUGAL OIL FILTER'S LIFE IS THE SAME AS THE ENGINE'S AND IS MAINTENANCE

FREE.

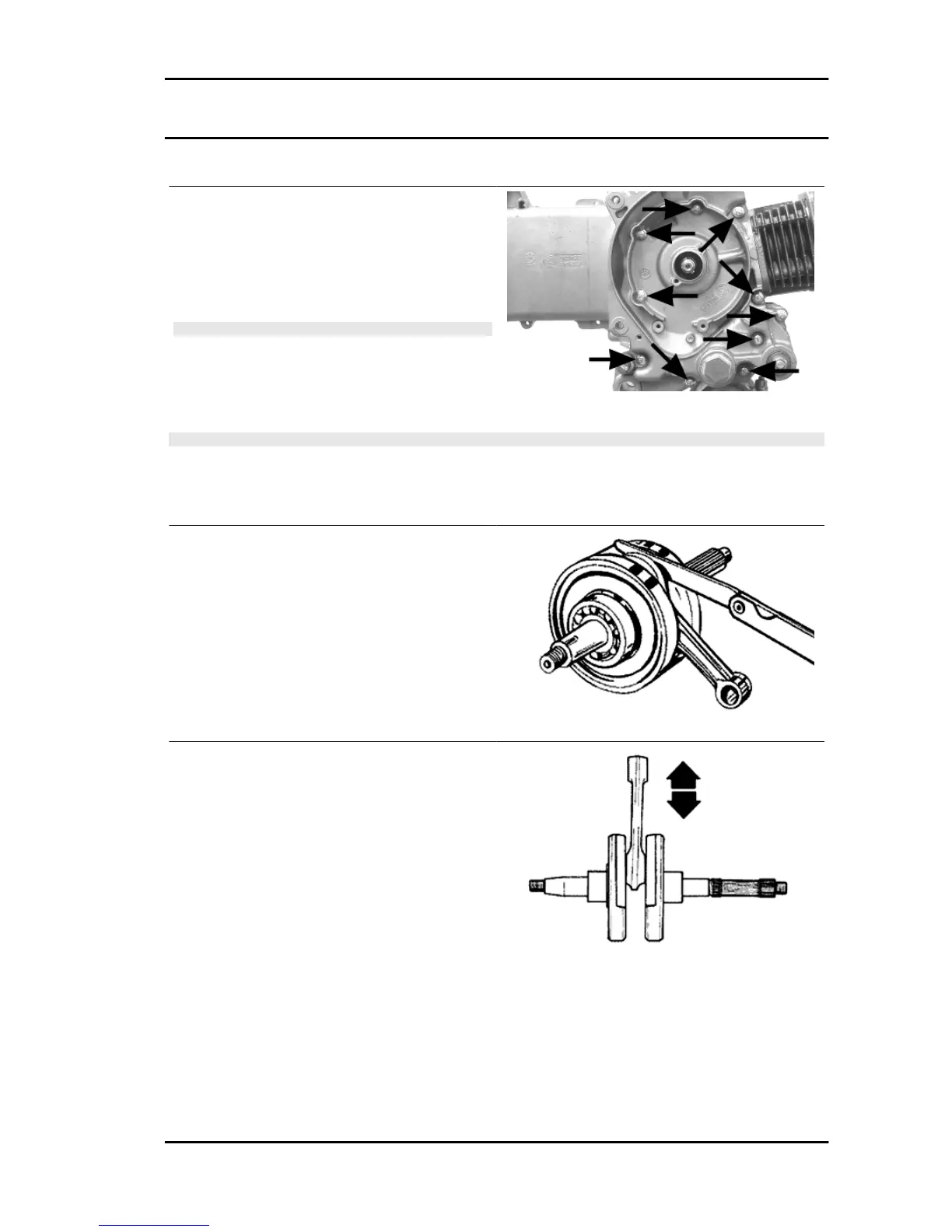

- Check the axial clearance on the connecting rod.

Fitting clearance

Standard connecting rod axial clearance 0.15 ÷

0.30 mm Max. connecting rod clearance 0.5 mm

- Check the correct radial clearance of the con-

necting rod by holding the driving shaft with your

hands and, with a dial gauge fitted to the rod small

end, measuring the clearance, move the connect-

ing rod vertically as shown in the figure.

Fitting clearance

Connecting rod radial - standard clearance

0.006 ÷ 0.018 mm Connecting rod max. - radial

clearance 0.25 mm

MSS ZIP 100 4T Engine

ENG - 107

Loading...

Loading...