0.15 mm

Headlight adjustment

Proceed as follows:

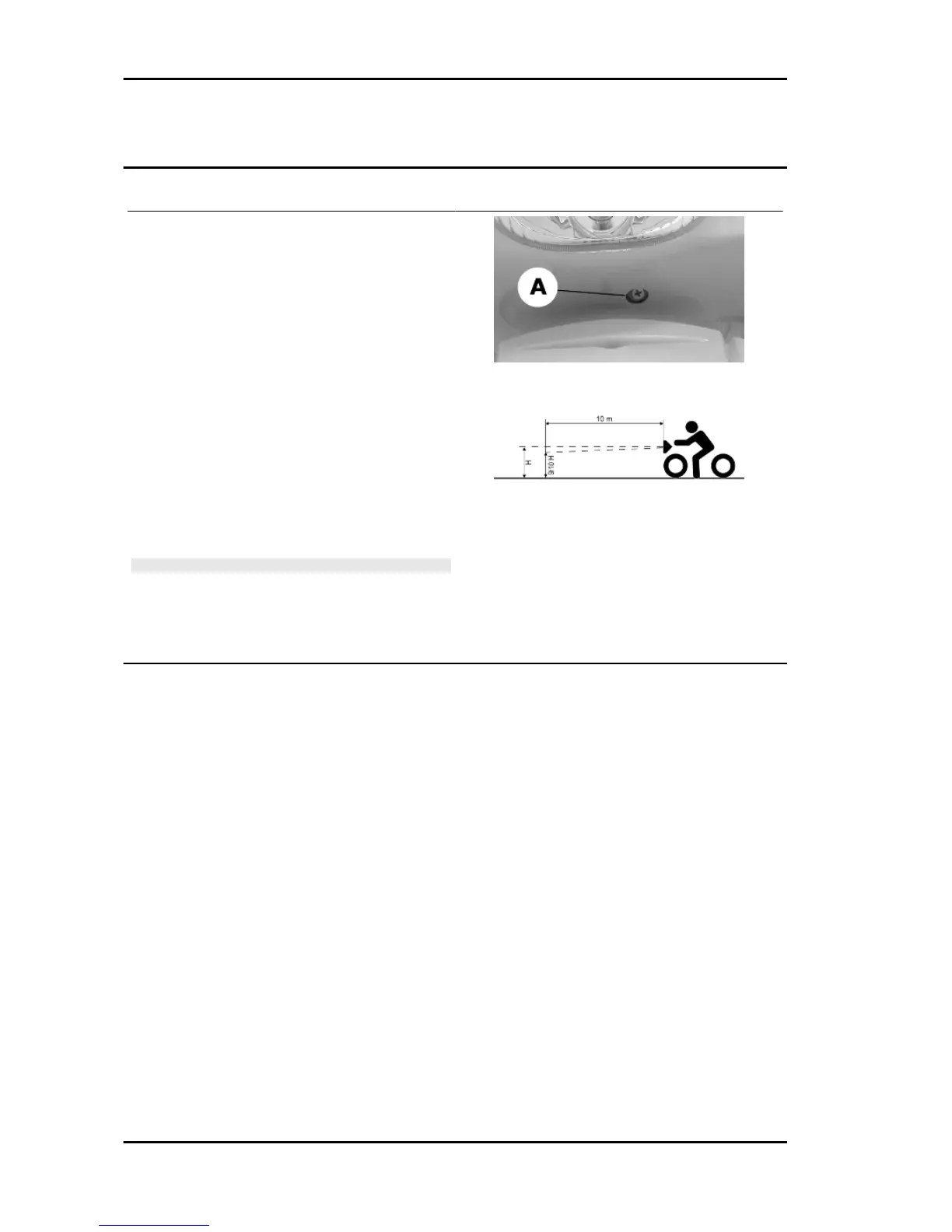

1. Place the vehicle, in running order and with the

tyres inflated to the prescribed pressure, on a flat

surface 10-m away from a white screen situated in

a shaded area, making sure that the longitudinal

axis of the scooter is perpendicular to the screen;

2. Turn on the headlight and check that the bor-

derline of the projected light beam on the screen

is not higher than 9/10 or lower than 7/10 of the

distance from the ground to the centre of vehicle

headlamp;

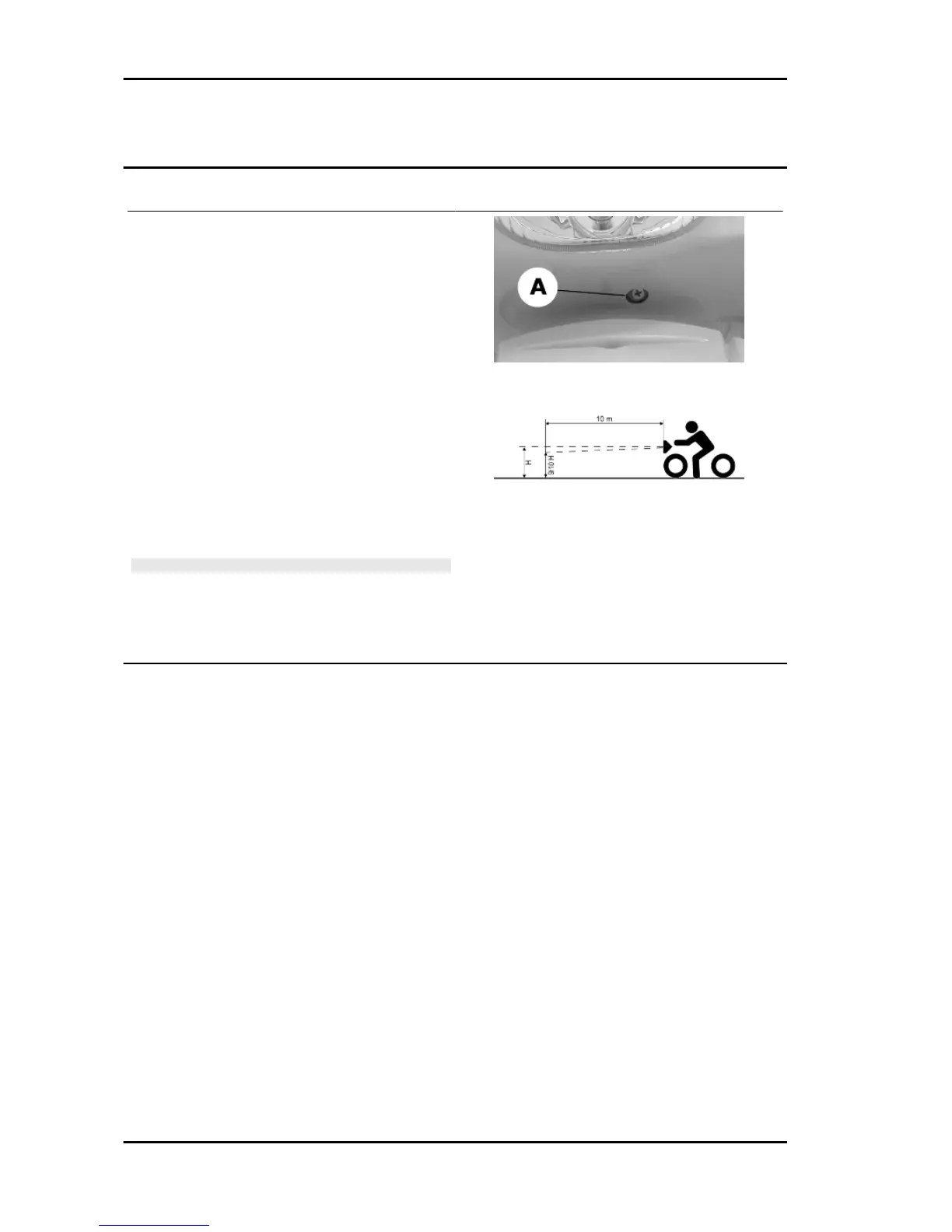

3. If otherwise, adjust the right headlight with screw

«A».

N.B.

THE ABOVE PROCEDURE COMPLIES WITH THE EURO-

PEAN STANDARDS REGARDING MAXIMUM AND MINI-

MUM HEIGHT OF LIGHT BEAMS. REFER TO THE STATU-

TORY REGULATIONS IN FORCE IN EVERY COUNTRY

WHERE THE VEHICLE IS USED.

CO check

- CO checking may be necessary when an engine operation failure is detected or during engine idle

speed adjustment operations.

- This test must be carried out after washing all carburettor parts carefully, the air filter must be clean

and the ignition spark plug in good conditions.

1) warm up the vehicle travelling on the streets at about 50 km/h for ~5 minutes; time enough for the

automatic starter to exclude the circuit.

2) Shut off the vehicle only for the time required to carry out steps 3) and 4).

3) Connect a - 50 cm extension pipe to the exhaust fumes intake in the muffler.

4) Make sure the muffler and the pipe are adequately connected and tight. Insert the exhaust fumes

analyser probe into the pipe.

5) Connect the tester thermometer to the sump, using a cover with oil expressly prepared for probes.

6) Start the engine and before adjusting the idle speed, make sure that the oil temperature is between

70÷80 °C.

7) Wait until the idle speed stabilises for one minute.

8) Without operating the accelerator again and using the flow screw rev the engine at 1500±150

rpm.

Maintenance MSS ZIP 100 4T

MAIN - 36

Loading...

Loading...