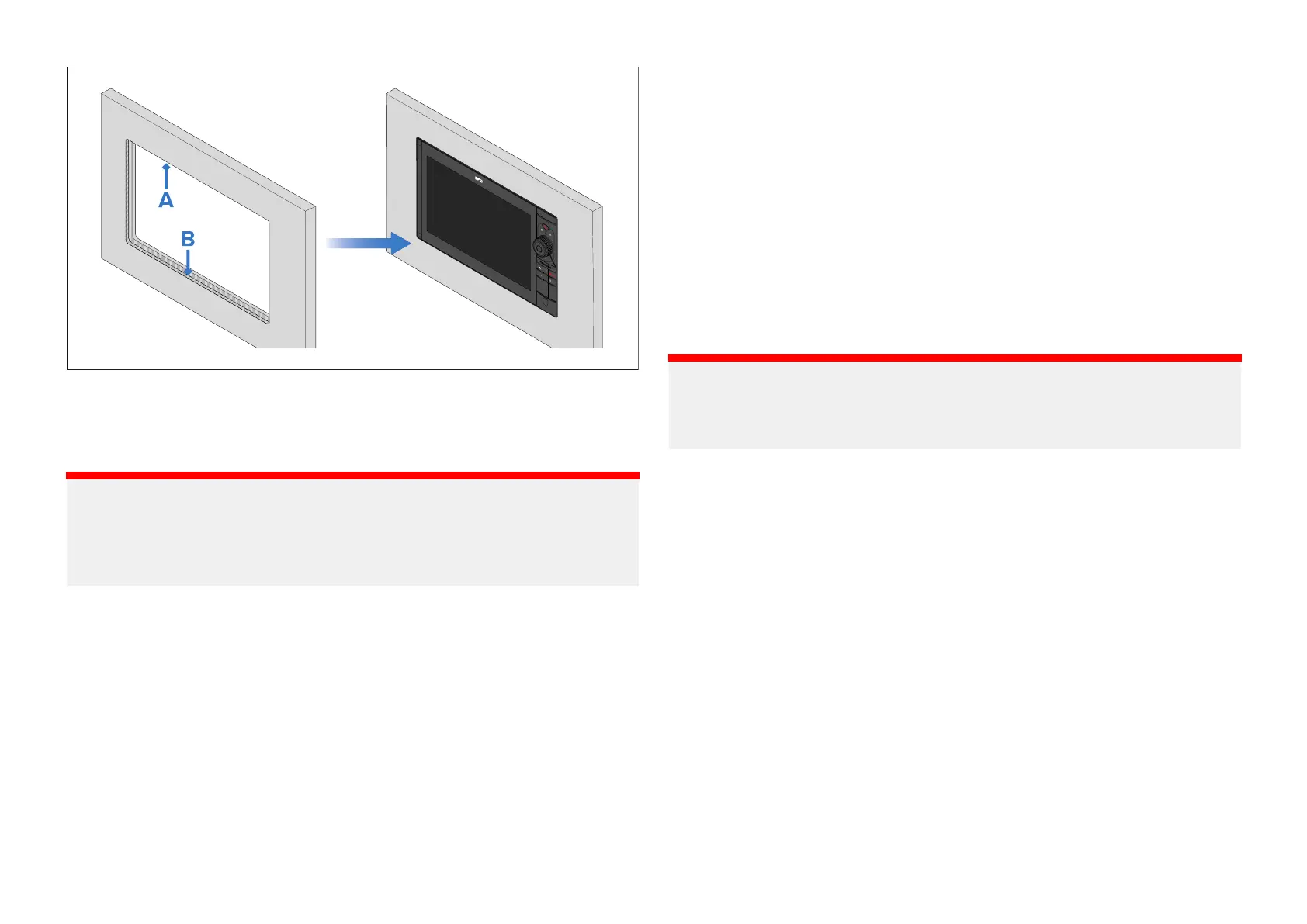

•A—Cutout(whenflushmountingthecutoutwillbethesamesizeas

forsurfacemounting.

•B—Flushmountingrequiresane xtrarebatetorecessthedisplayfullyin

themountingsurface.

Important:

Whenflushmountingthefixingsgothroughholesdrilledintherebated,

andthereforethinnest,partofthemountingsurface .Beforepreparingthe

mountingsurfaceensurethatsufficientthicknesswillremaintosecure

thedisplay.

1.MarktheCutoutlineidentifiedonthesuppliedmountingtemplateon

themountingsurface .

2.Markthe4holeforfixingscrewslocationsidentifiedonthesupplied

mountingtemplateonthemountingsurface.

3.MarktheRebateforflushmountlineidentifiedonthesuppliedmounting

templateonthemountingsurface.

4.Useadrillandanappropriatesizedrillbitorholecuttertocutoutthe

cornersoftheCutoutline.

Thecornerdiameterforthedisplaysare:

•33.00mm(1.30in)—Axiom®2Pro9.

•37.00mm(1.47in)—Axiom®2Pro12.

•38.00mm(1.5in)—Axiom®2Pro16.

5.Useajigsaworsimilarcuttingtooltocutouttheremainderofthecut

outarea.

6.Drillthe4fixingsholesatthemarkedlocationusinga3.7mm(

5

/

32

”)

drillbit.

7.Usearouterhandtooltorecessthemarkedrebateareatoadepthof

15.00mm(0.59in).

8.Useahalfroundfileand/orsandpapertosmoothandroughedgesor

bursonthecutouthole.

Flushmounting

Followthestepsbelowtoflushmountthedisplay.

Important:

Inabovedecksinstallations,marine-gradesealantshouldbeusedtoseal

thegapbetweentheedgeofthemountingsurfaceandtheedgeofthe

display.

Installation45

Loading...

Loading...