Program a Function Block Diagram

Rockwell Automation Publication 1756-PM009G-EN-P - February 2018 21

Operator request inputs to an instruction are always cleared by the instruction

when it executes. This lets operator interface work with these instructions by

setting the desired mode request bit. You do not have to program the operator

interface to reset the request bits. For example, if an operator interface sets

the OperAutoReq input to a PIDE instruction, when the PIDE instruction

executes, it determines the appropriate response and clears the

OperAutoReq.

Program request inputs are not normally cleared by the instruction because

these are normally wired as inputs into the instruction. If the instruction

clears these inputs, the input would get set again by the wired input. There

might be situations where you want to use other logic to set the Program

requests to be cleared by the instruction. In this case, set the

ProgValueReset input and the instruction always clears the Program mode

request inputs when it executes.

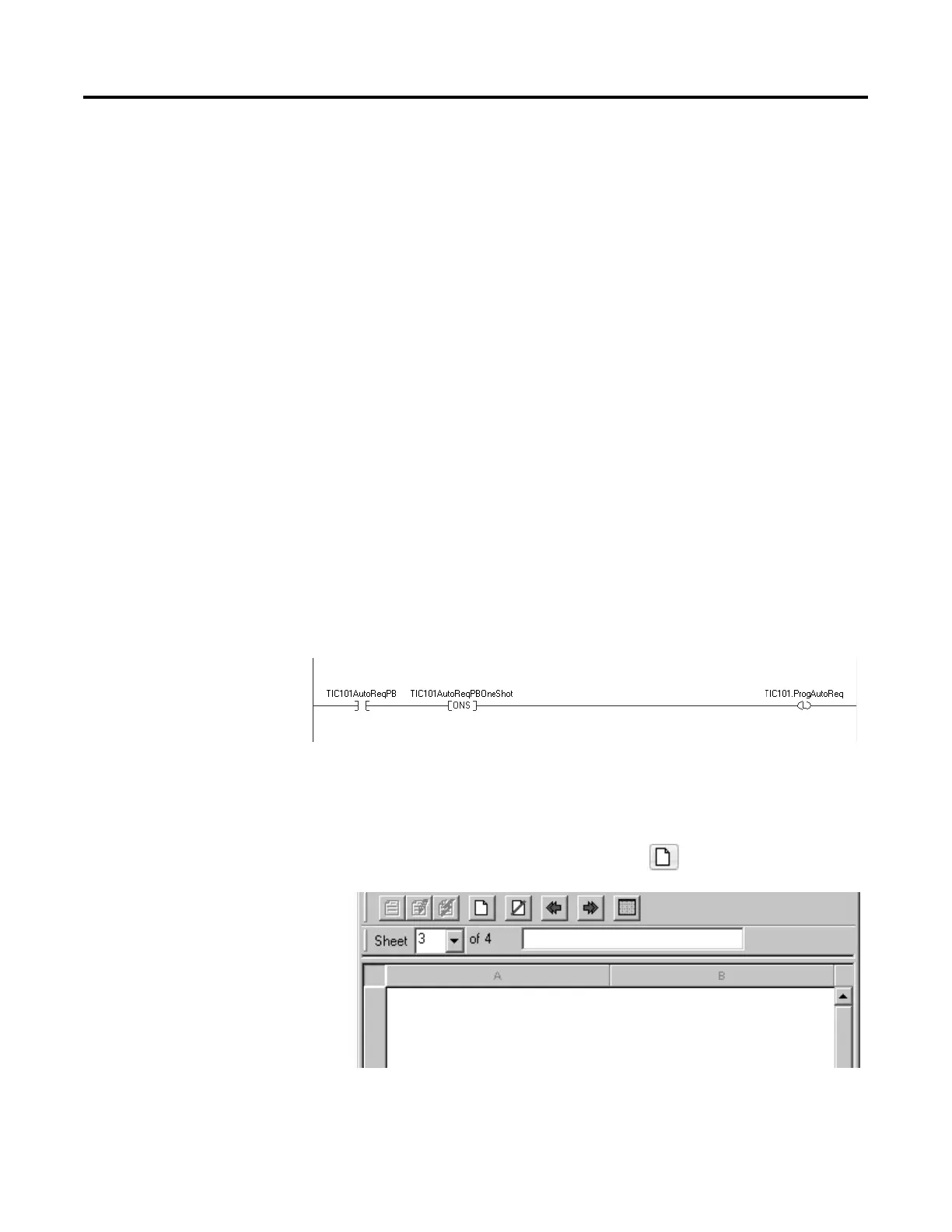

In this example, a rung of ladder logic in another routine is used to one-shot

latch a ProgAutoReq input to a PIDE instruction when a push button is

pushed. Because the PIDE instruction automatically clears the Program mode

requests, you do not have to write any ladder logic to clear the ProgAutoReq

input after the routine executes. The PIDE instruction receives only one

request to go to Auto every time the push button is pressed.

Example: When the TIC101AutoReq button is pressed, one-shot latch ProgAutoReq for the PIDE

instruction TIC101.

TIC101 is configured with the ProgValueReset input set, so when the PIDE instruction

executes, it automatically clears ProgAutoReq.

To add a sheet to a function block routine:

1. On the Sheet toolbar, click Add Sheet .

Loading...

Loading...