Installation

52/121 Revision 05 • INSTALLATION AND OPERATING INSTRUCTIONS • 8DJH • 500-8067.9

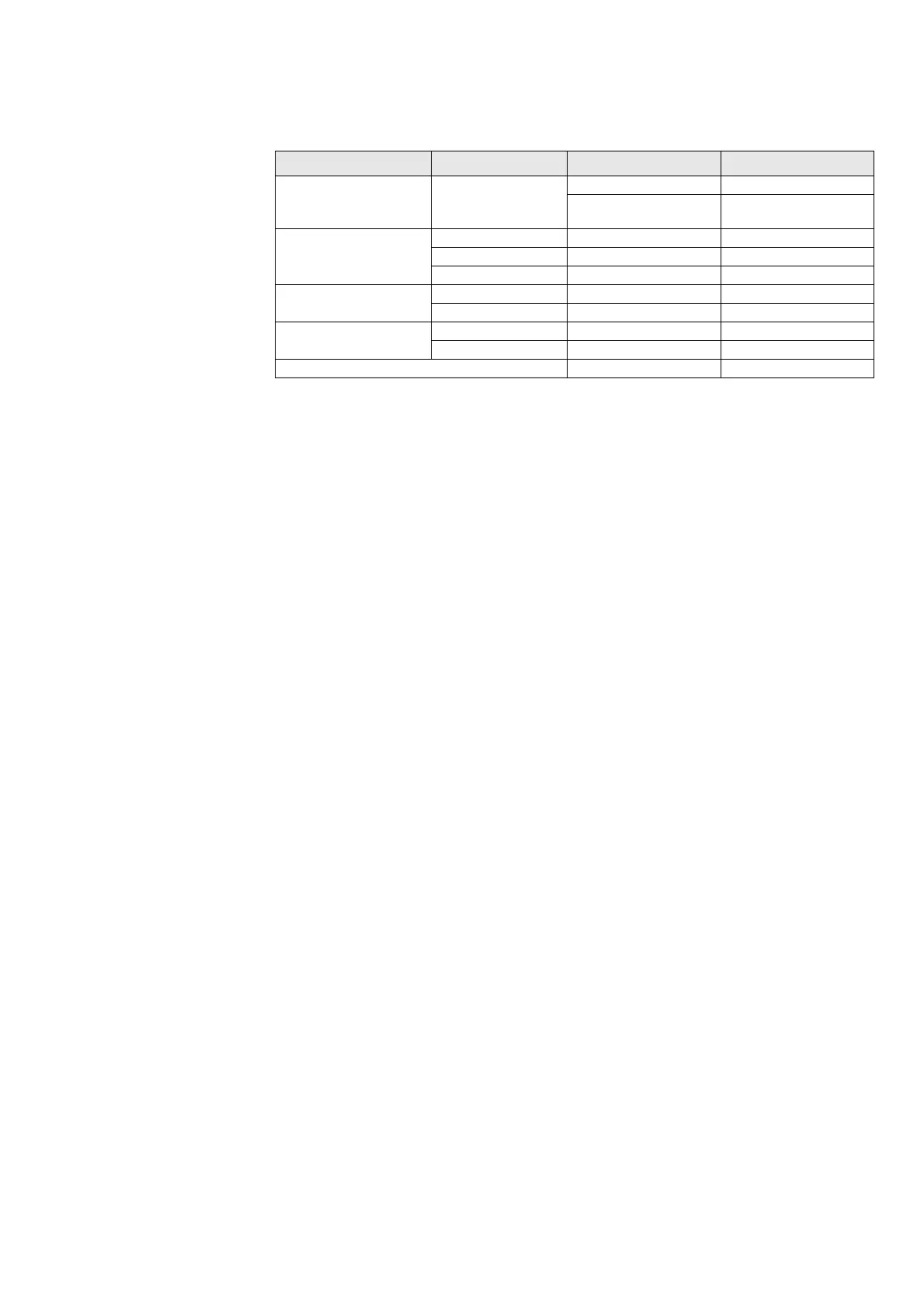

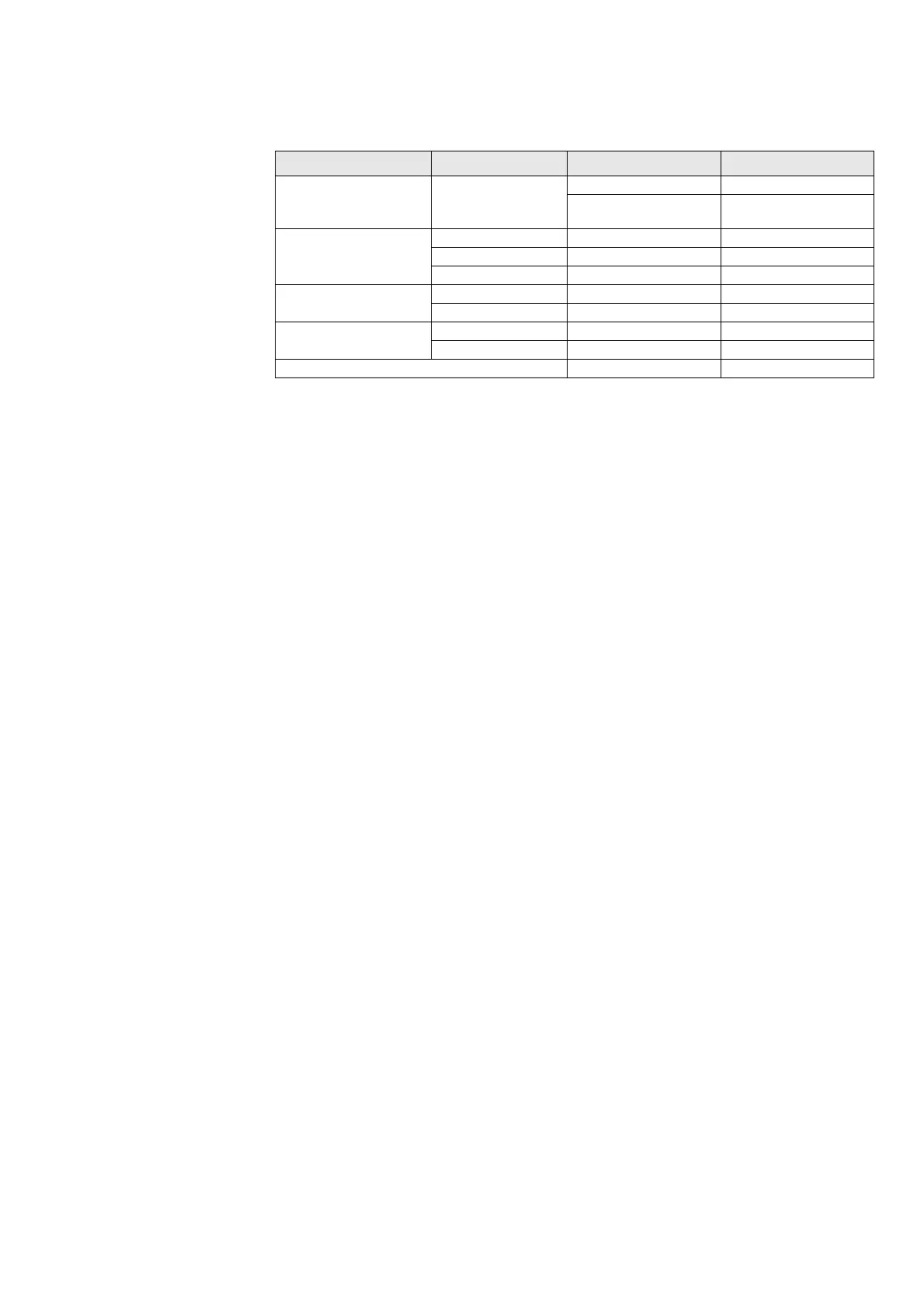

12.4 Tightening torques

If not stated otherwise, the following tightening torques apply to 8DJH switchgear:

12.5 Comments on electromagnetic compatibility

To achieve appropriate electromagnetic compatibility (EMC), some basic requirements must

be observed while erecting the switchgear. This applies especially to the installation and

connection of external cables and wires.

Basic measures for ensuring EMC are already taken during design and assembly of the

switchgear panels. Among other things, these measures include:

• The low-voltage compartment is an integral part of the panel, which means that the

protection and control devices with the internal wiring are metal-enclosed.

• Reliable earth connections of the frame parts via toothed contact washers or locking

washers.

• Inside the panel, wires are laid in metal ducts.

• Spatial separation of sensitive signal wires from wires with high interference voltage levels.

• Limitation of switching overvoltages of inductive loads (e.g. relay or contactor coils, motors)

by means of protective circuits with diode, varistor or RC element.

• Within the low-voltage compartment, the secondary devices are mounted in defined zones.

• Shortest possible connection between corresponding modules in subracks.

• Consideration of the magnetic leakage fields of conductor bars and cables.

• Protection of subracks and wiring backplanes against interference by perforated shielding

plates.

• Large surface bonding between all modules and devices as well as bonding to the earthing

conductor of the switchgear assembly.

These measures basically enable proper operation of the switchgear itself. The planner or

operator of the switchgear must decide whether additional measures are required depending

on the electromagnetic environment where the switchgear is installed. Such measures must

be implemented by the installation company in charge.

In an environment with heavy electromagnetic interference it may be necessary to use

shielded cables and wires for the external connections. This makes it possible to avoid

interferences in the low-voltage compartment and thus, undesired influences on the

electronic protection and control or other automation devices.

Cable shields must be electrically bonded to be able to carry high frequencies, and contacted

concentrically at the cable ends.

The shields of cables and wires are connected and earthed in the low-voltage compartment.

Connect the shields to earth potential - with high electrical conductivity and all around as far

as possible. Protect the contact surfaces from corrosion in case of humidity (regular

condensation).

Joint Material/material Thread Tightening torque

Metal joints sheet-steel/sheet-steel

e. g.: front plates, top

plates, etc.

M6 (self-tapping) 12 Nm

M8 30 Nm

Earthing busbar sheet-steel/copper M8 21 Nm

copper/copper M8 21 Nm

sheet-steel/copper M10 30 Nm

Current conductor joint copper/copper M8 21 Nm

copper/copper M10 30 Nm

Switchgear earthing sheet-steel/cable lug M12 50 Nm*

cable shield earthing M10 30 Nm*

Cable plugs M16 max. 50 Nm*

* The tightening torque at the cable lug joint depends on:

• Material of cable lug

• Instructions of sealing end manufacturer

• Instructions of cable manufacturer

Loading...

Loading...