Installation

48/121 Revision 05 • INSTALLATION AND OPERATING INSTRUCTIONS • 8DJH • 500-8067.9

➭ Observe the adhesive label with transport information provided on the switchgear.

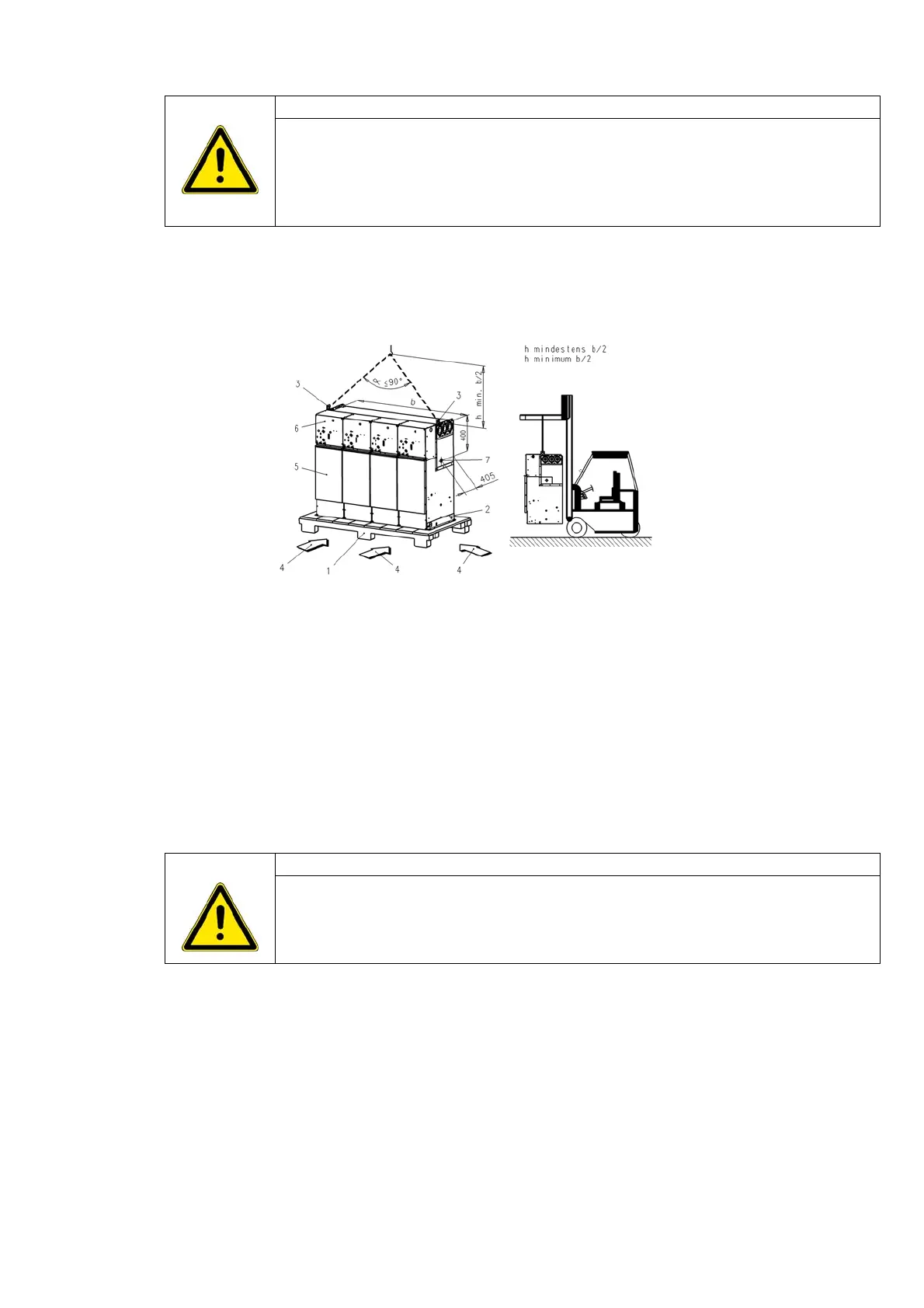

- The angle between the crane chains at the lifting facility must be less than 90°.

- The distance between the transport eyes and the lifting facility must be at least half the

switchgear width.

➭ Lift or lower just slowly, as the switchgear will swing into the center of gravity when it is

lifted.

➭ While lifting, observe parts laid inside such as cable-type transformers, connecting cables.

11.2 Packing

The transport units can be packed as follows:

• On pallets, covered with PE protective foil

• In a seaworthy crate (switchgear is sealed with desiccant bags in PE foil)

• Other packings in special cases (e.g. latticed crate, cardboard cover for airfreight)

Transport unit Transport units consist either of individual panels or panel blocks with max. four functions,

and the switchgear accessories. The switchgear accessories are packed in the cable

compartment of the first panel or in a separate transport box, depending on the extent.

ATTENTION

Danger due to transport units falling down. The center of gravity of the transport units is not

always located under the fixing point.

➭ Lift the transport units slowly.

➭ There must be no persons standing in the swinging area of lifted transport units.

➭ Transport only transport units with a max. width of 2.00 m or max. height of 2.60 m.

Fig. 22: Adhesive label with transport information on the

switchgear (example)

①

Pallet

②

Bolted joint between

transport unit and pallet

③

Transport eyes

④

Clearance for fork-lift trucks

⑤

Cable compartment cover

⑥

Ready-for-service indicator

⑦

Center of gravity

ATTENTION

Packing and consumable materials of the switchgear must be disposed of in an

environmentally compatible way or recycled.

➭ Observe local regulations for disposal and environmental protection.

Loading...

Loading...