59/301

Siemens Building Technologies Basic Documentation LMV5... CC1P7550en

HVAC Products 4 Burner control 13.08.2004

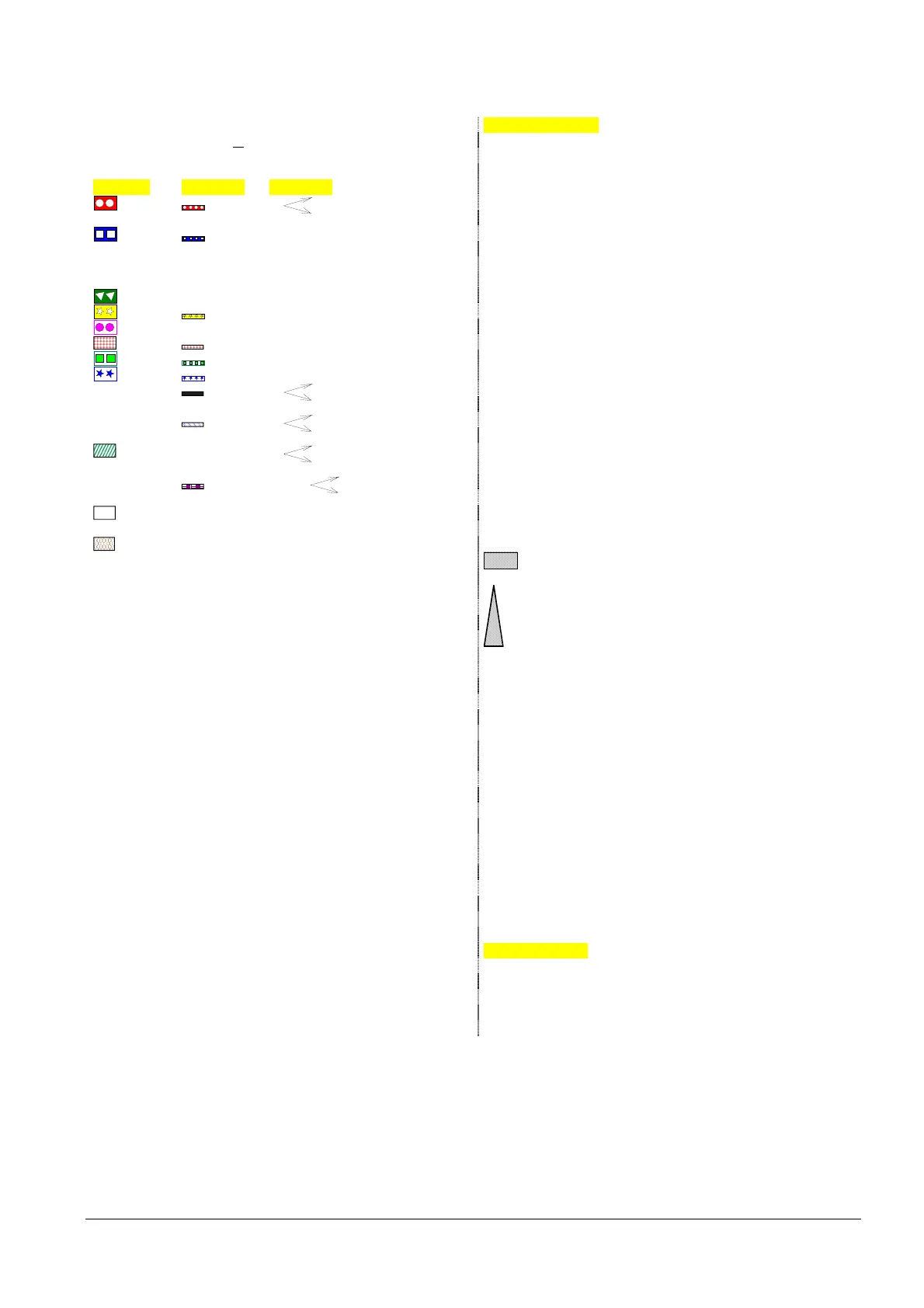

Assignment of times:

t0 Postpurge lockout position

Depending on the parameter, VP takes place:

between Ph62 and Ph70 or

/and

between Ph30 and Ph32 t01 MaxT_SafetyPhase

t10 MinTimeHomeRun

Signal ON Signal OFF Next phase t21 MinT_StartupRel

t22 FanRunupTime

01

00, Rep = 0

12, Rep > 0

t30 PrepurgePt1

t34 PrepurgePt3

t36 MinOnT_OilPump

t38 PreignitionT_Gas / Oil

Parameter direct start

Checking with controller on

Deviation → 10

No Rep. decrement t42 PreignitionT_Off

10 t44 Interval1 Gas / Oil

70 t52 Interval2 Gas / Oil

Without VP70 with VP80 t62 MaxTimeLowFire

62 t70 AfterburnTime

Stop, up to Ph – max. time → 01 t74 PostpurgeT1 Gas / Oil (tn1)

Stop, up to Ph – max. time → 10 t78 PostpurgeT3 Gas / Oil (tn3)

t80 VP_EvacTime

0 – 3 s

01

00, Rep = 0

12, Rep > 0

t81 VP_TimeAtmPress

t82 VP_FillTime

0 – 30 s

01

00, Rep = 0

12, Rep > 0

t83 VP_TimeGasPress

tmx1 MaxDampRunTime

0 – 3 s

01

00, Rep = 0

12, Rep > 0

tmx2 MaxT_StartupRel

tmx3 MaxT_CircHOil

Param.

79

10

TSA1 SafetyTime1

TSA2 SafetyTime2

Input: don´t care

Output: OFF tv PrepurgeTime_Gas / Oil

Output: ON

Permissible positioning range

1) Parameter: With / without PM

2) Parameter: Short / long preignition time for oil only

Short / long oil pump – ON – time

3) Delayed shutdown within TSA1 + TSA2

4) Parameter: Output as startup signal / PM relief valve

In Standby: actuator can travel within the permissible po-

sitioning range, but is always driven to the home position.

Must be in the home position before changing the phase

5) Parameter: Normal / direct startup

0° Position as supplied (0°) Normal startup → sequential phase = 10

Direct startup → sequential phase = 79 90° Actuator fully open (90°)

(when R = ON)

6) Sequential phase = 24 FGR Flue Gas Recirculation

7) Only with valve proving during startup CPI Closed Position Indicator

8) Parameter: With / without alarm on prevention of startup AD Air damper

9) Parameter: With continuous purging PS-VP Pressure Switch-Valve Proving

FCC Fan Contactor Contact 10) Fan controlled as before

Running time when LOCK OUT = T_FanLockout LF Low-fire position

11) Parameter: With / without extraneous light test in STANDBY APS Air Pressure Switch

12) With valve proving during startup Startup phase 10 PS Pressure Switch

13) Parameter: Normal / continuous purging PoP Post-Purge position

Normal purging: Checking for off in 10, stop to HP Home Position

Ph-max time → 01 SR Safety Relay

Continuous purging: Checking for on in 10 and SLT Safety Limit Thermostat

12, Stop up to Ph-max time → 01 TL Temperature Limiter

14) Parameter: “OilPressureMin”, “akt_from_ts“ → no check IGN Ignition position

before TSA1 (LO, HO) or TSA2 (LOgp, HOgp)

15) Parameter: “GasPressureMin“, “deakt_xOGP“ → PSmin can Repetition counter:

be deactivated for oil programs with gas pilot

16) Parameter: “OilPumpCoupling“, “direct_coupl“ → SVoil has k) Heavy oil

to be connected to output “Oil pump / magnetic l) Restricted startup behavior

clutch“. Output is active when fan is on and for n) Restricted safety chain

another 15 s after fan is switched off

17) Parameter: “Start / PSvalve“, “PS_Reli_Inv“→ Output PS valve will be logically inverted

18) Parameter: “Alarm act / deact“, “deactivated“→ The alarm output can temporarily be deactivated (for current error only)

19) Parameter: Only with LMV52...: Continuous pilot gas / oil: Activated → Pilot valve is also activated in operation

20) Parameter: Only with LMV52...: Extraneous light, pilot phase, operating phase gas / oil → Separate flame supervision possible

21) Parameter: Only with LMV52...: DW-DK / CPI or StartReleaseGas → Parameter-dependent ON / OFF test

CPI Gas: OFF test for gas trains only

CPI Oil: OFF test for oil trains only

CPI Gas+Oil: OFF test for gas and oil trains

Legend to the sequence diagrams

Loading...

Loading...