Commissioning

5.6 Function commissioning

SINAMICS V20 Inverter

82 Operating Instructions, 07/2012, A5E03728167

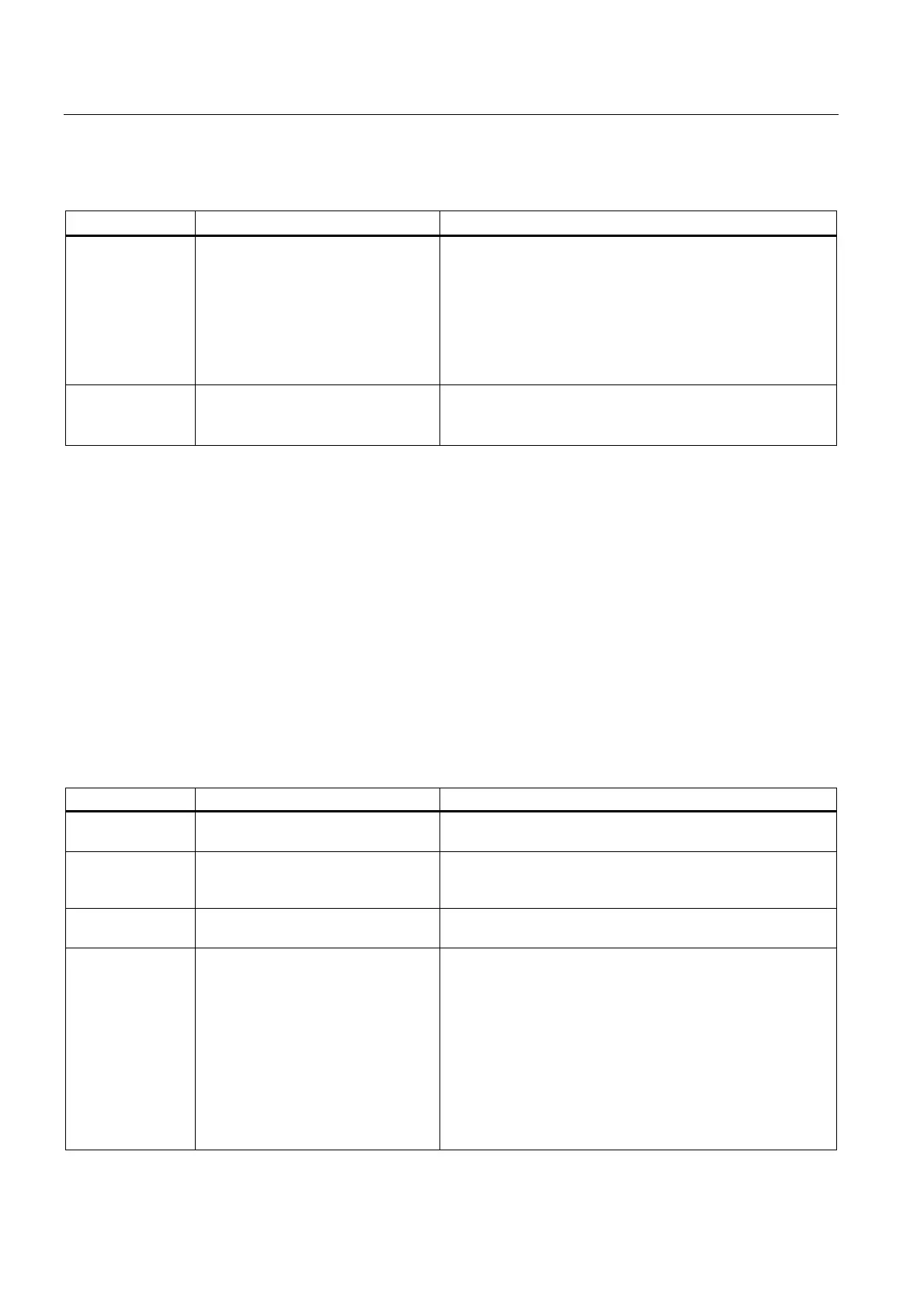

Setting parameters

Parameter Function Setting

P1240[0...2] Configuration of Vdc controller This parameter enables / disables Vdc controller.

= 0: Vdc controller disabled

= 1: Vdc_max controller enabled (factory default)

= 2: Kinetic buffering (Vdc_min controller) enabled

= 3: Vdc_max controller and kinetic buffering (KIB) enabled

Note: This parameter must be set to 0 (Vdc controller

disabled) if a braking resistor is used.

P0210 Supply voltage [V] This parameter defines the supply voltage. Its default value

depends upon the type of inverter.

Range: 0 ... 1000

5.6.2.9 Setting the load torque monitoring function

Functionality

The load torque monitoring function allows the mechanical force transmission between the

motor and driven load to be monitored. This function can detect whether the driven load is

blocked or the force transmission has been interrupted.

The inverter monitors the load torque of the motor in different ways:

● Motor blocking detection

● Load missing detection

● Belt failure detection

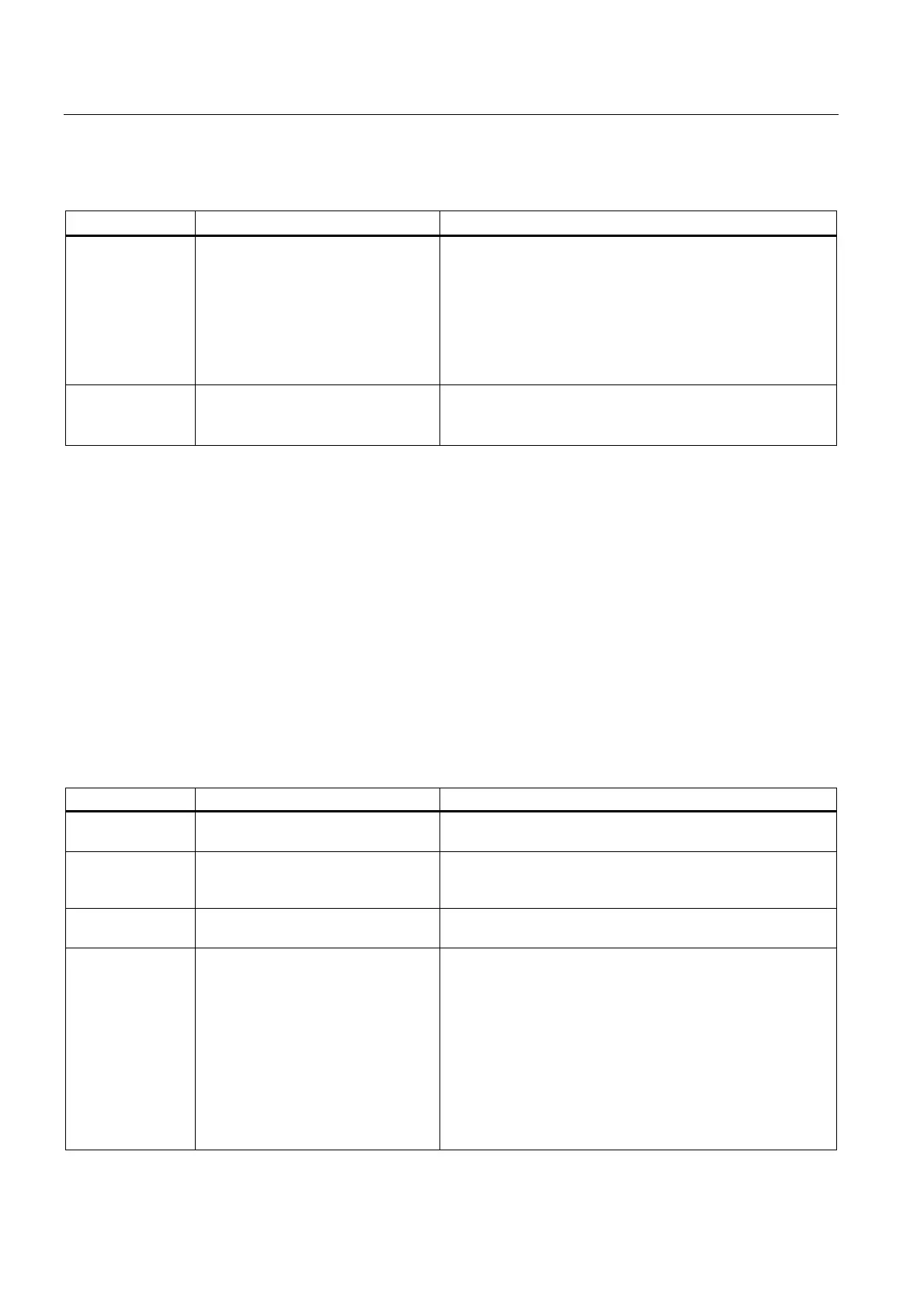

Setting parameters

Parameter Function Setting

P2177[0...2] Delay time for motor is blocked [ms] Defines the delay time for identifying that the motor is blocked.

Range: 0 ... 10000 (factory default: 10)

P2179 Current limit for no load identified [%] This parameter defines the threshold current for A922 (load

missing) relative to P0305 (rated motor current).

Range: 0.0 ... 10.0 (factory default: 3.0)

P2180 Delay time for load missing [ms] Defines the delay time for identifying that the load is missing.

Range: 0 ... 10000 (factory default: 2000)

P2181[0...2] Belt failure detection mode The belt failure detection is achieved by comparing the actual

frequency / torque curve with a programmed envelope

(defined by parameters P2182 ... P2190). If the curve falls

outside the envelope, a warning or trip is generated.

= 0: Belt failure detection disabled (factory default)

= 1: Warning: Low torque / frequency

= 2: Warning: High torque / frequency

= 3: Warning: High / low torque / frequency

= 4: Trip: Low torque / frequency

= 5: Trip: High torque / frequency

= 6: Trip: High / low torque / frequency

Loading...

Loading...