5-10 FUEL SYSTEM

ASSEMBLY

Assembly is reverse order of disassembly with special atten-

tion to the following steps.

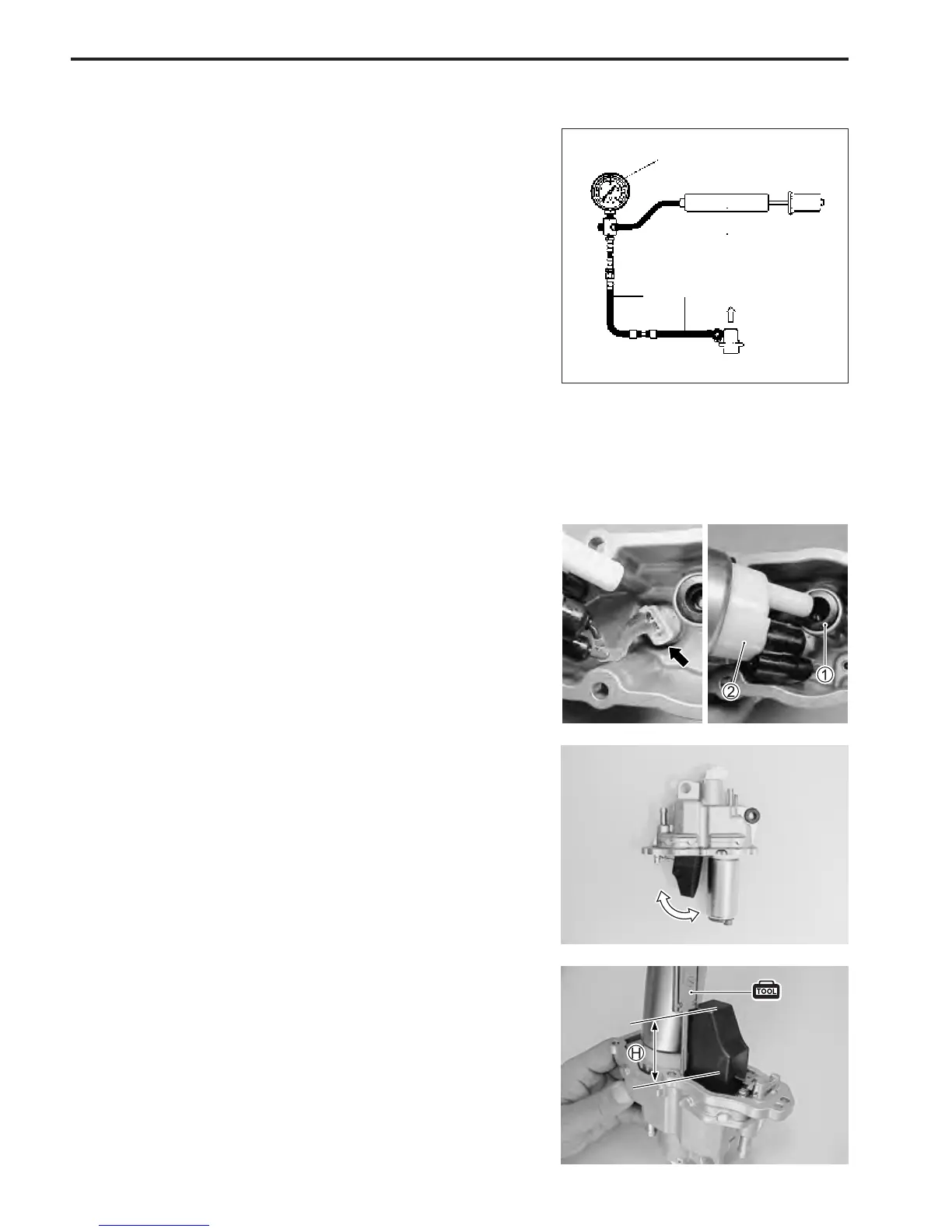

High pressure fuel pump

Connect pump lead wire connector, then install grommet 1 and

fuel pump 2.

NOTE:

Apply fuel to grommet before installing.

Float / Float pin

Install float and float pin.

NOTE:

After assembling, check for smooth and free float movement.

Checking float height

Measure float height.

\ 09900-20101 : Vernier calipers

Float height

HH

HH

H : 43 ± 1 mm

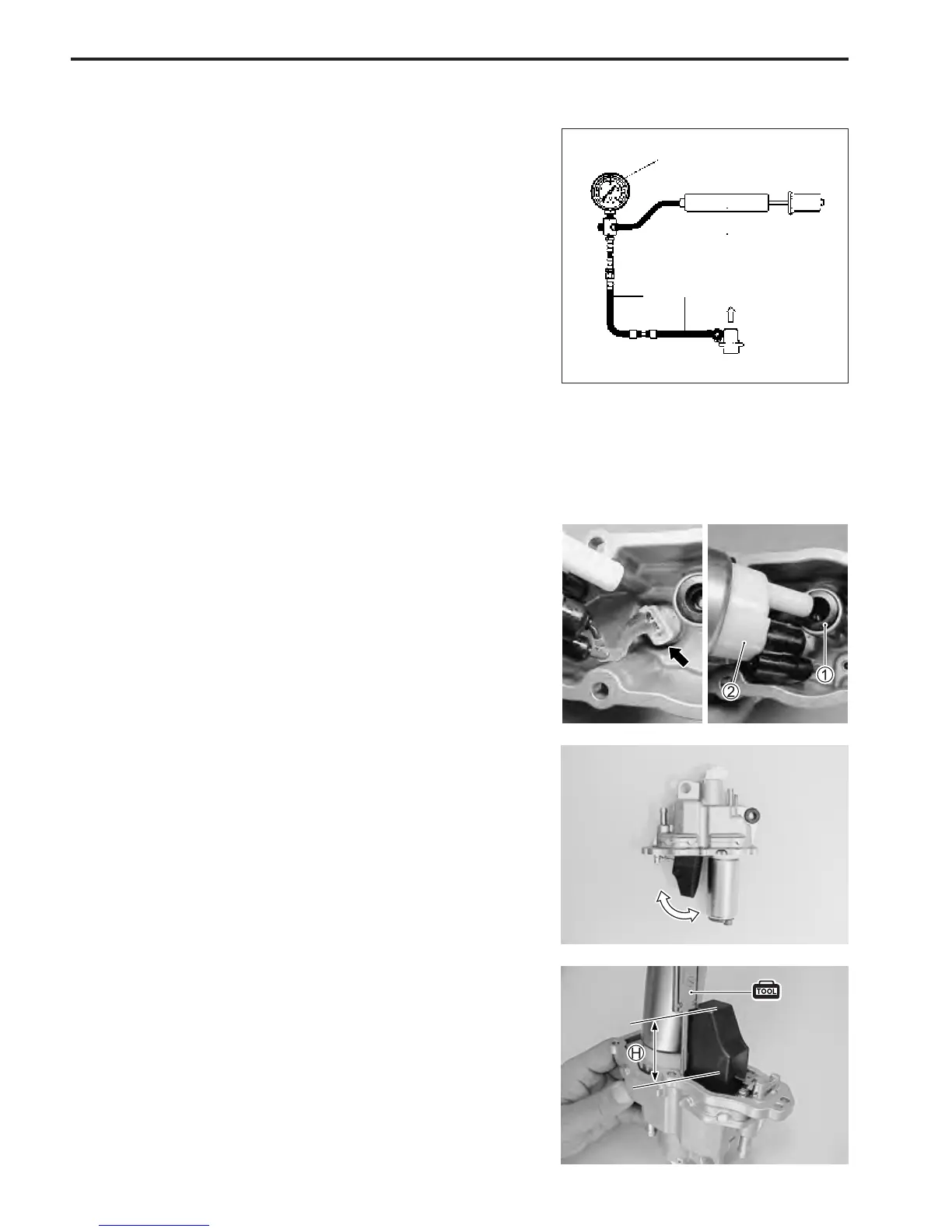

Fuel pressure regulator

Check fuel pressure regulator operation.

\ 09952-99310 : Hand air pump 1

09940-44121 : Air pressure gauge 2

09940-44130 : Attachment 3

09912-58490 : Hose 4

1. Connect special tools to inlet side of regulator as shown in

figure.

2. Pump air into regulator using pump 1 until air is released

through outlet side.

3. Read pressure on gauge when air is released.

Regulator operating pressure :

240 – 270 kPa (2.4 – 2.7 kg/cm

2

, 34.1 – 38.4 psi)

If out of specification, replace regulator.

1

2

3

4

NOTE:

Make sure that float weight is not applied to needle valve.

Loading...

Loading...