POWER UNIT 6-43

INSPECTION / SERVICING

NOTE:

If cracks, excessive wear or other damage is found on any com-

ponent, replace component.

CYLINDER

Cylinder distortion

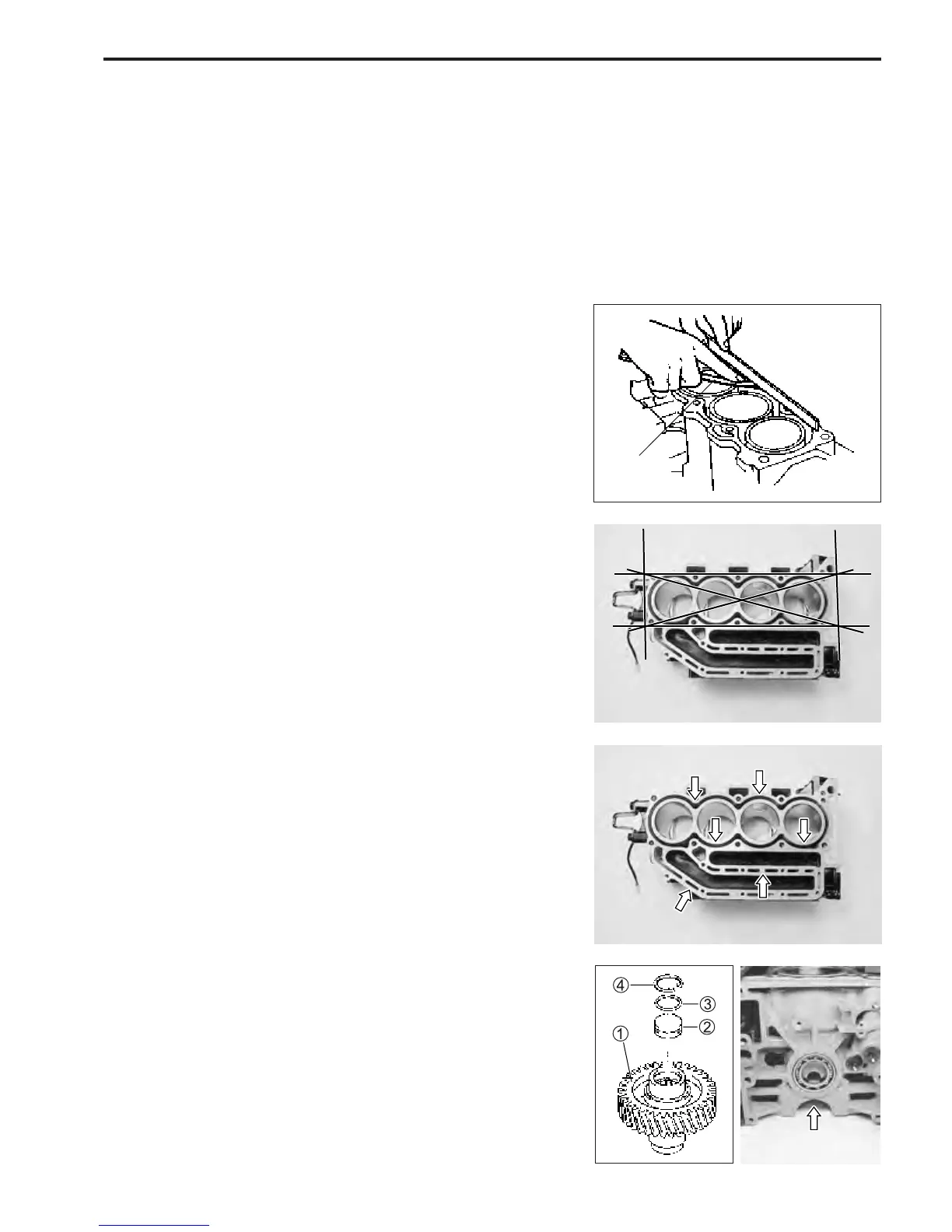

Using a straightedge and thickness gauge, measure cylinder

distortion (gasketed surface) at a total of six (6) locations as

shown in figure.

\ 09900-20803 : Thickness gauge

Cylinder distortion :

Service limit : 0.05 mm (0.002 in.)

If measurement exceeds service limit, resurface or replace

cylinder.

NOTE:

Cylinder can be resurfaced, using a surface plate and # 400 grit

wet sandpaper.

Move cylinder in a figure eight pattern when sanding.

Water jackets

Inspect water jackets for clog or obstruction.

Clean water jacket if necessary.

\

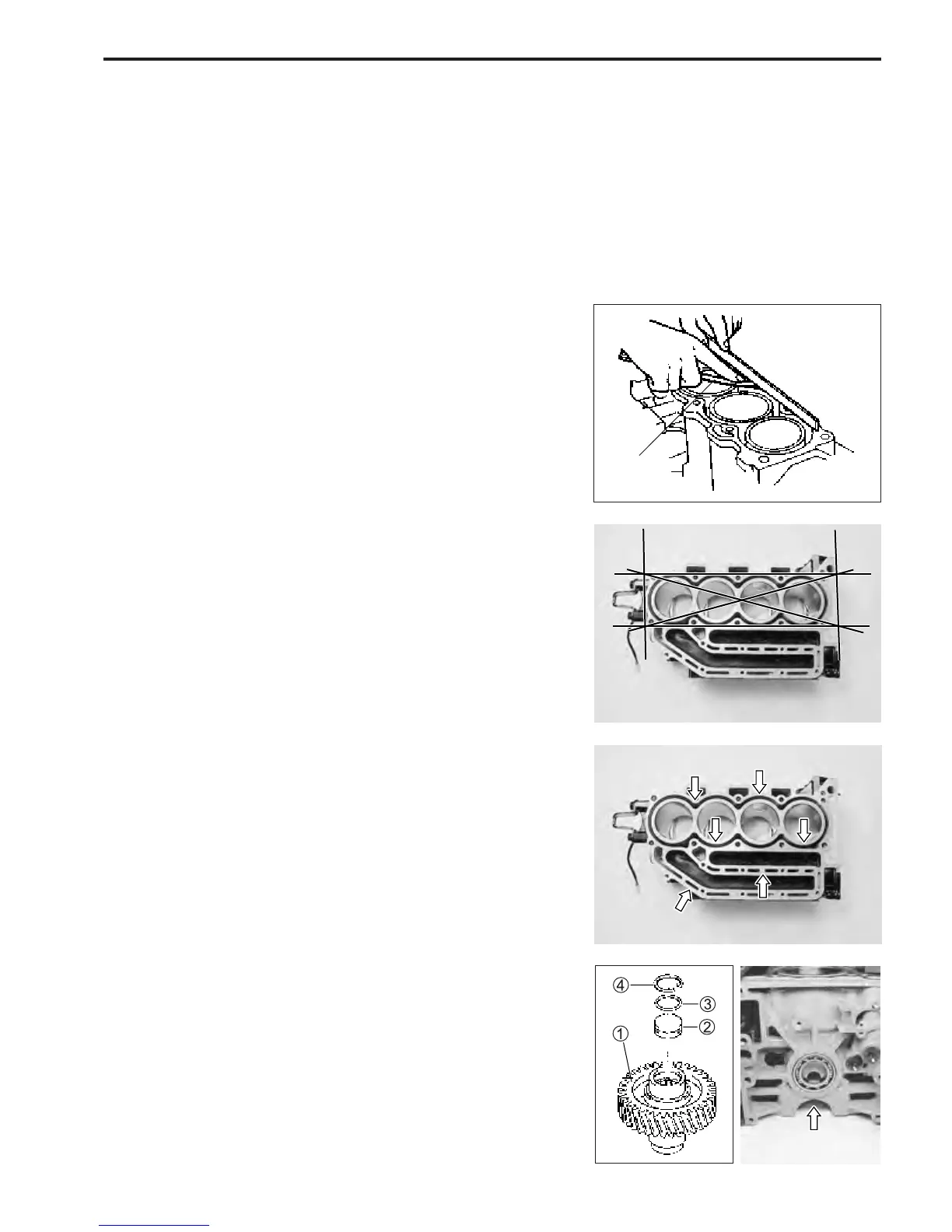

Driven gear / bearing

Inspect driven gear for wear or other damage.

Replace if necessary.

Inspect driven gear bearing for pitting, rough or other damage.

Replace if necessary.

1 Driven gear 2 Plug 3 O-ring 4 Circlip

Loading...

Loading...