ENGINE CONTROL SYSTEM 3-29

CONDITION FOR SELF-DIAGNOSTIC SYSTEM OPERATION

NOTE 1:

These conditions will be caused by IAC valve failure or incor-

rect by-pass air screw adjustment. If IAC valve is always closed

or by-pass air is too low, the ECM controls the IAC valve duty

to increase to maintain the idling / trolling speed specified.

NOTE 2:

This condition will be caused by clogged pressure detect pas-

sage in intake manifold.

FAILED ITEM CONDITION

MAP sensor 1

CKP sensor

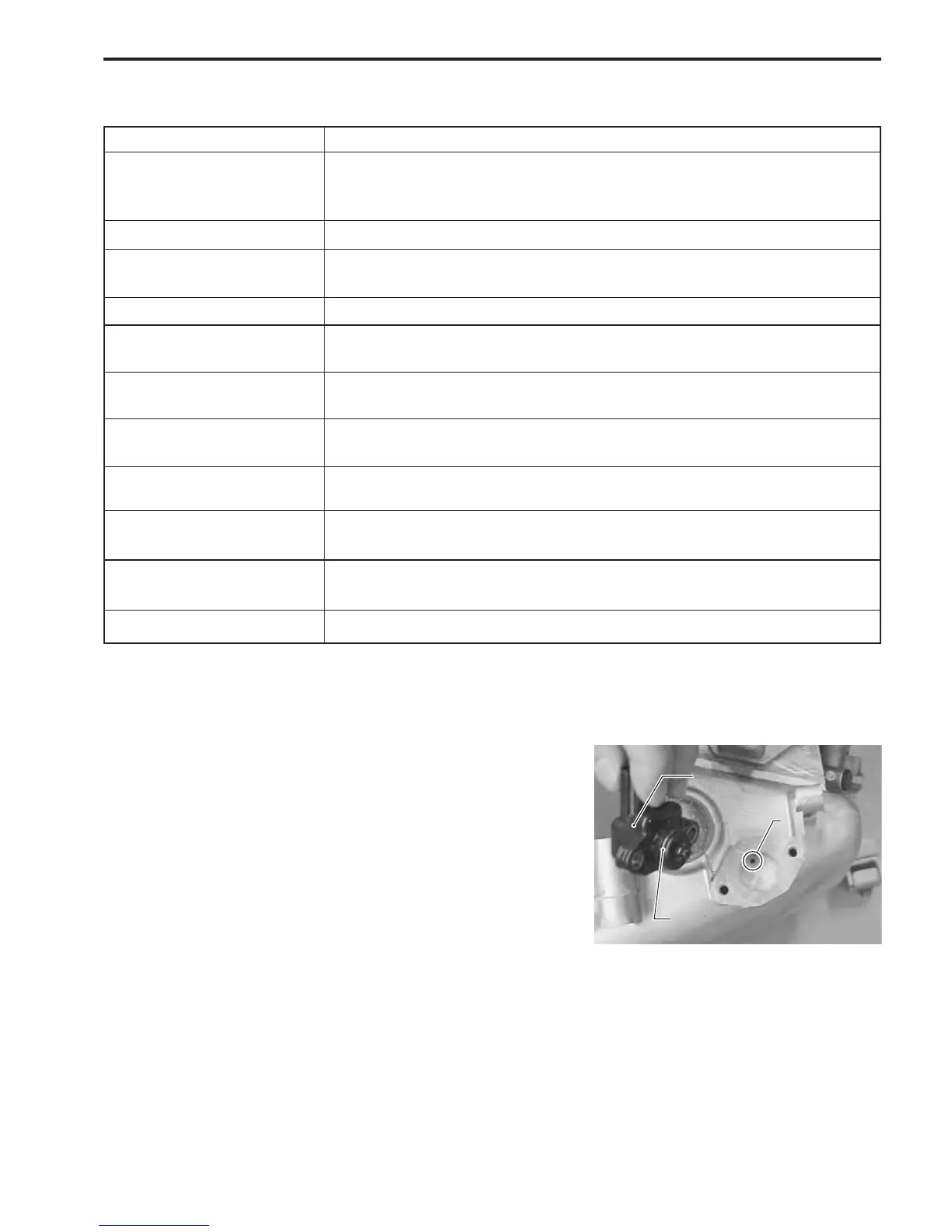

CMP sensor

CTP switch

Cylinder temp. sensor

IAT sensor

MAP sensor 2

(Pressure detect passage)

Rectifier & regulator

(Over-charging )

Exhaust manifold temp. sensor

IAC valve / By-pass air screw

adjustment

• During one crankshaft rotation, 34 signals are not input to the ECM

• No signal (With engine running)

• Receiving an out of range “37–860 mmHg (0.20–4.53V)” signal

(With engine running)

• IAC valve operates at 90% duty or higher when CTP switch is “ON”

[NOTE 1]

• During two crankshaft rotations, 4 signals are not input to the ECM

• Receiving “ON” signal when engine speed is 2500 r/min. or higher and intake

manifold pressure is 319 mmHg or higher

• No signal

• Receiving an out of range “– 46 to +170 °C (0.10 – 4.63V)” signal

• No signal

• Receiving an out of range “– 46 to +178 °C ( 0.04 – 4.46V)” signal

• Receiving unchanging signal regardless engine speed change

[NOTE 2]

• Receiving 16 volts or higher signal

• No signal

• Receiving an out of range “– 46 to +170 °C (0.10 – 4.63V)” signal

Fuel injector • No operation signal from the ECM

PassagePassage

CMP sensorCMP sensor

O-ringO-ring

Loading...

Loading...