Maintenance

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.Toro.comandsearching

foryourmachinefromtheManualslinkonthehomepage.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

•Beforeadjusting,cleaning,repairing,orleaving

themachine,dothefollowing:

–Parkthemachineonalevelsurface.

–Movethethrottleswitchtothelow-idleposition.

–Disengagethecuttingunits.

–Lowerthecuttingunits.

–Ensurethatthetractionisinneutral.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifthecuttingunitsareinthetransportposition,use

thepositivemechanicallock(ifavailable)before

youleavethemachineunattended.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Usejackstandstosupportthemachineor

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

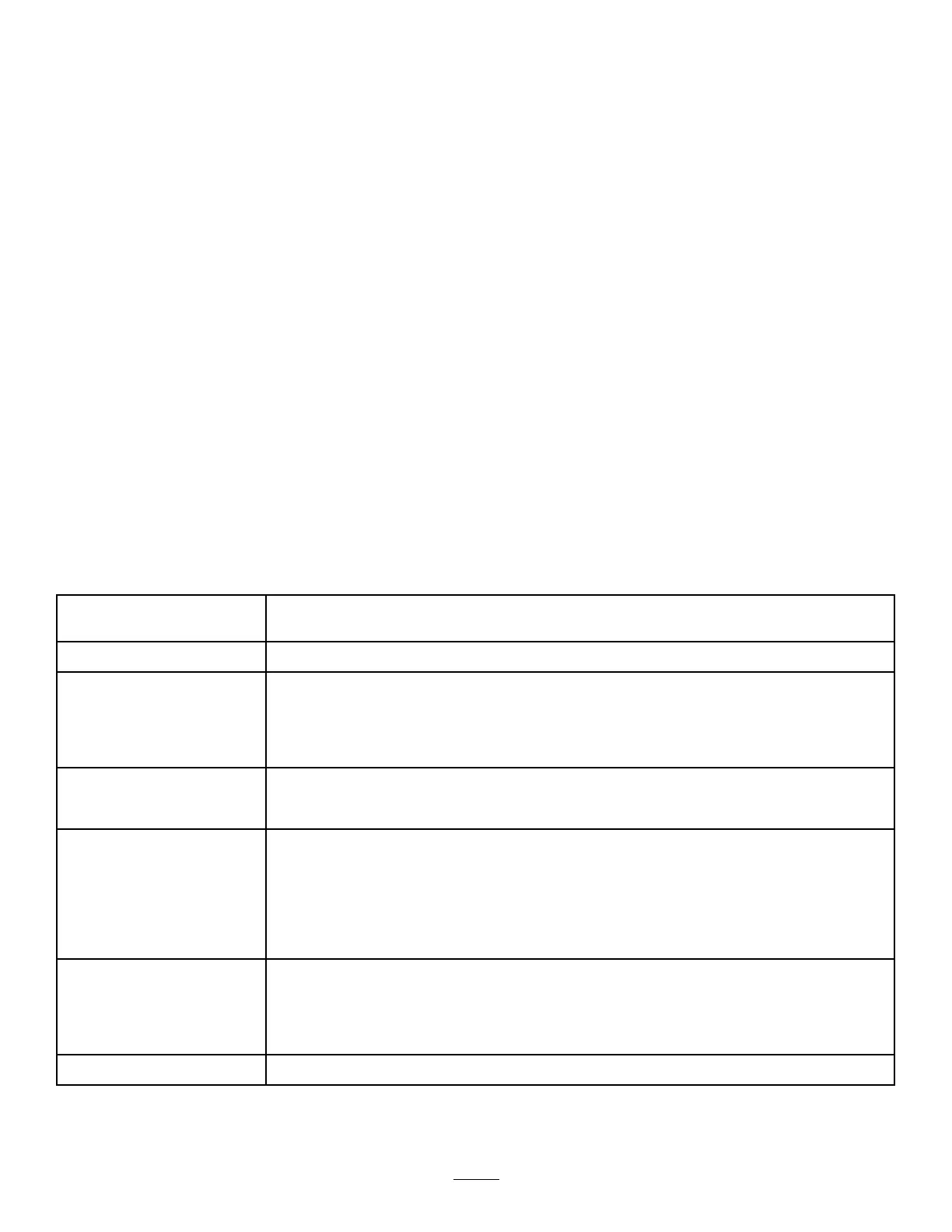

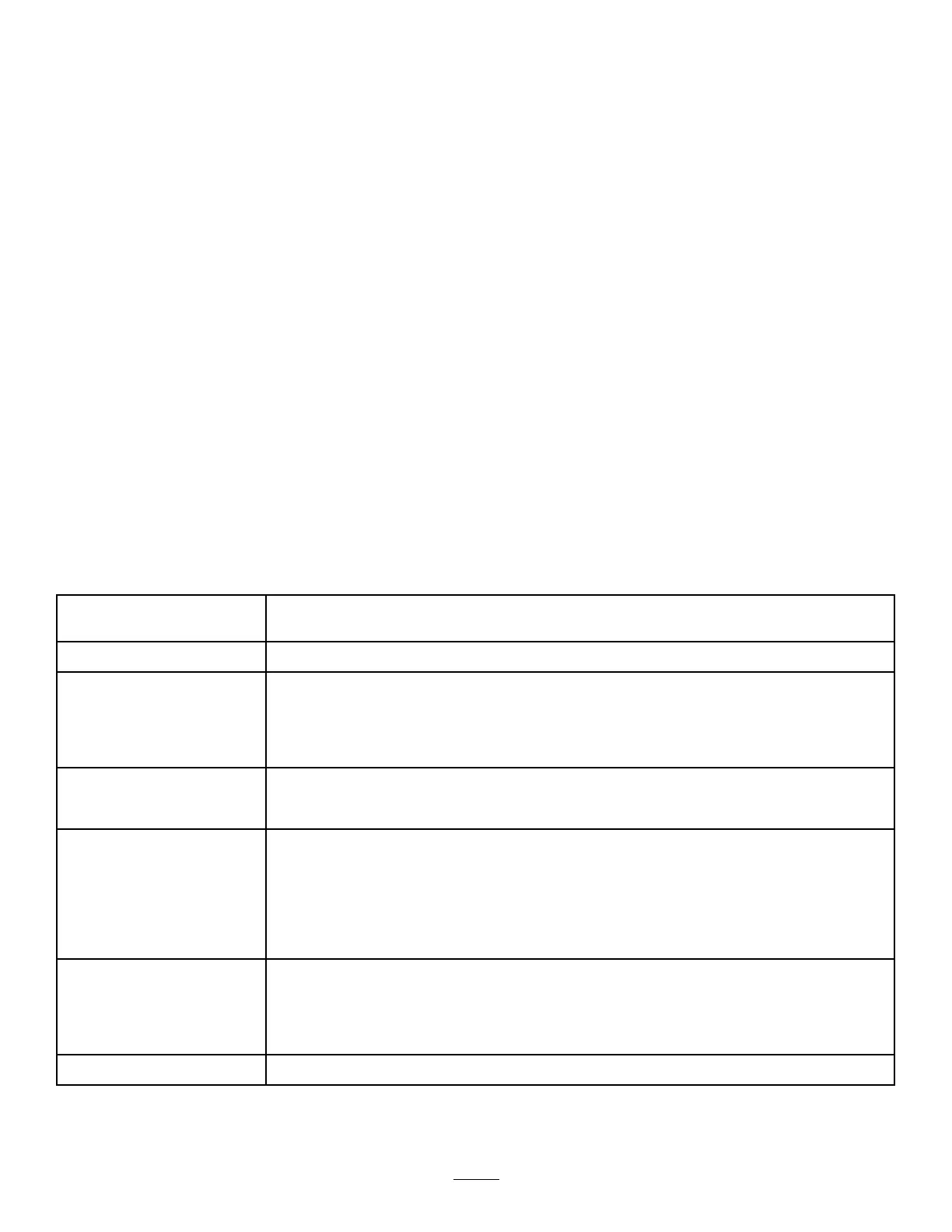

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Torquethewheel-lugnuts.

Aftertherst10hours

•Torquethewheel-lugnuts.

•Checkandadjusttheservicebrakes.

•Checkthetensiononthealternatorbelt.

•CheckthetensiononthePTObelt.

•Changethehydraulic-uidlter.

Aftertherst50hours

•Changetheengineoilandlter.

•Checkandadjusttheservicebrakes.

•CheckthetensiononthePTObelt.

Beforeeachuseordaily

•Checktheairpressureinthetires.

•Checktheinterlocksystem.

•Checktheair-cleanerindicator.

•Checktheengine-oillevel.

•Checkthecoolingsystemandthecoolantlevel.

•Checkthehoodscreenandradiatorfordebris.

•Checkthehydraulicsystemanduidlevel.

Every50hours

•Greasethebearingsandbushings.

•Inspecttheair-cleanerelement.

•Checkthebattery-cableconnections.

•Checkthebatteryelectrolytelevelwheninoperation.

•Lubricatethebrakecables.

Every150hours

•Changetheengineoilandlter.

35

Loading...

Loading...