FuelSystem

Maintenance

Note:RefertoFuelSpecication(page27)forproper

thefuelrecommendations.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwhereaspark

mayignitefuelfumes.

ServicingtheWater

Separator

ServiceInterval:Every400hours

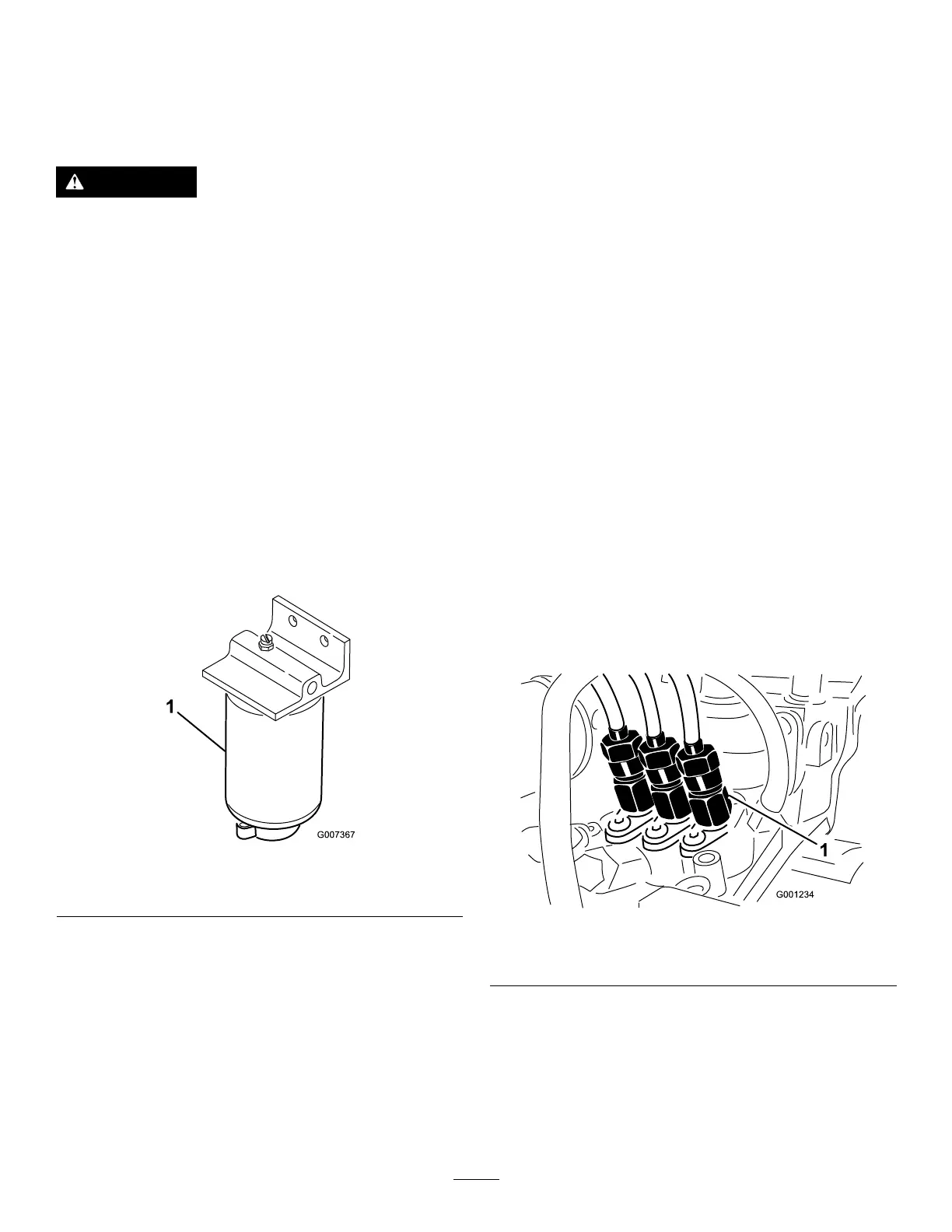

Drainthewaterorothercontaminantsfromthewater

separator(Figure49)daily.

1.Placeacleancontainerunderthefuellter.

2.Loosenthedrainplugonthebottomofthelter

canister(Figure49).

g007367

Figure49

1.Filtercanister

3.Cleantheareawheretheltercanistermounts.

4.Removetheltercanisterandcleanthe

mountingsurface.

5.Lubricatethegasketontheltercanisterwith

cleanoil.

6.Installtheltercanisterbyhanduntilthegasket

contactsmountingsurface,thenrotateitan

additional1/2turn.

7.Tightenthedrainplugonthebottomofthelter

canister.

CleaningtheFuelTank

ServiceInterval:Every400hours/Yearly(whichever

comesrst)—Drainandcleanthe

fueltank

Drainandcleantankiffuelsystembecomes

contaminatedorifyoustorethemachineforan

extendedperiod.Usecleandieselfueltoushout

thetank.

InspectingtheFuelLines

andConnections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Inspectthefuellinesfordeterioration,damage,or

looseconnections.

PurgingtheAirfromthe

Fuel-InjectorTubing

Note:Performthisprocedureonlyifyouhavepurged

airfromthefuelsystemusingthenormalpriming

proceduresandenginedoesnotstart;refertoPurging

theFuel-InjectionPump(page32).

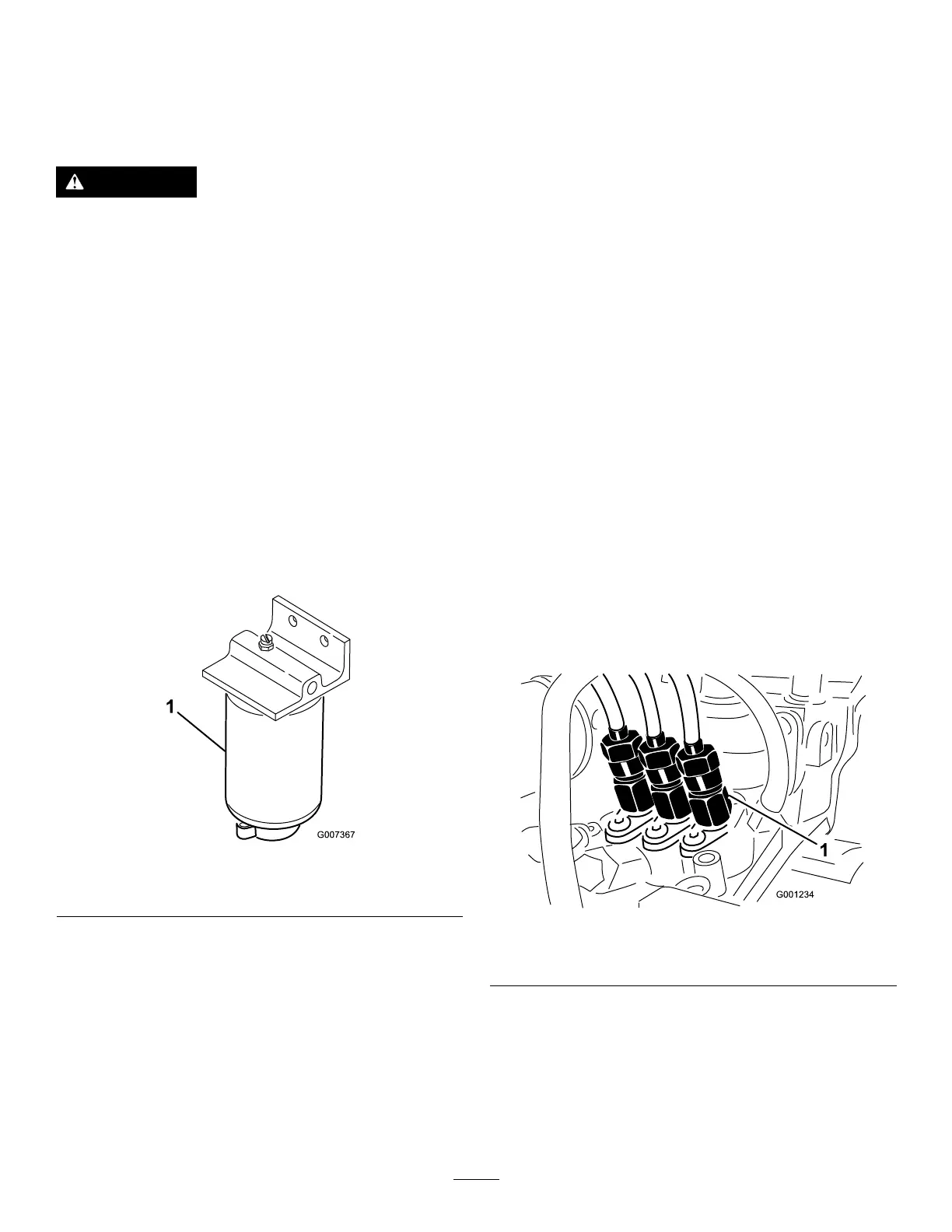

1.LoosenthetubenutattheNo.1injectornozzle

andholderassemblyattheinjectionpump

(Figure50).

g001234

Figure50

1.No.1injectornozzle

2.MovethethrottletotheFASTposition.

3.RotatethekeyswitchtotheSTARTpositionand

watchthefuelowaroundthetubenut.

4.RotatethekeyswitchtotheOFFpositionwhen

youattainasolidowoffuelfromthetube.

5.Tightenthetubenutsecurely.

45

Loading...

Loading...