MaterialProperties:

Viscosity,ASTMD445cSt@40°C55to62

cSt@100°C9.1to9.8

ViscosityIndexASTM

D2270

140to152

PourPoint,ASTMD97-35°Fto-46°F

IndustrySpecications:

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT,JohnDeereJ20C,

Vickers35VQ25,andVolvoWB-101/BM

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicuidisavailablein20ml(2/3oz)

bottles.Abottleissufcientfor15to22L(4to6US

gallons)ofhydraulicuid.OrderPartNo.44-2500

fromyourauthorizedTorodistributor.

ServicingtheHydraulic

System

PreparingtoServicetheHydraulic

System

1.Movemachinetoalevelsurfaceandengage

theparkingbrake.

2.PlaceallcontrolsintheNEUTRALpositionand

starttheengine.

3.Runtheengineatlowestpossibleenginespeed

topurgethesystemofair.

Important:DonotrunthePTO.

4.Cyclesteeringwheelseveraltimesfullytothe

leftandright,andalignthesteeringwheels

straightforward.

CheckingtheHydraulicSystem

andFluidLevel

ServiceInterval:Beforeeachuseordaily

Note:Thetransaxlehousingactsasthereservoir

forthehydraulicsystem.

1.Raisethedecktoextendthedeck-liftcylinders,

shutofftheengine,andremovethekeyfrom

thekeyswitch.

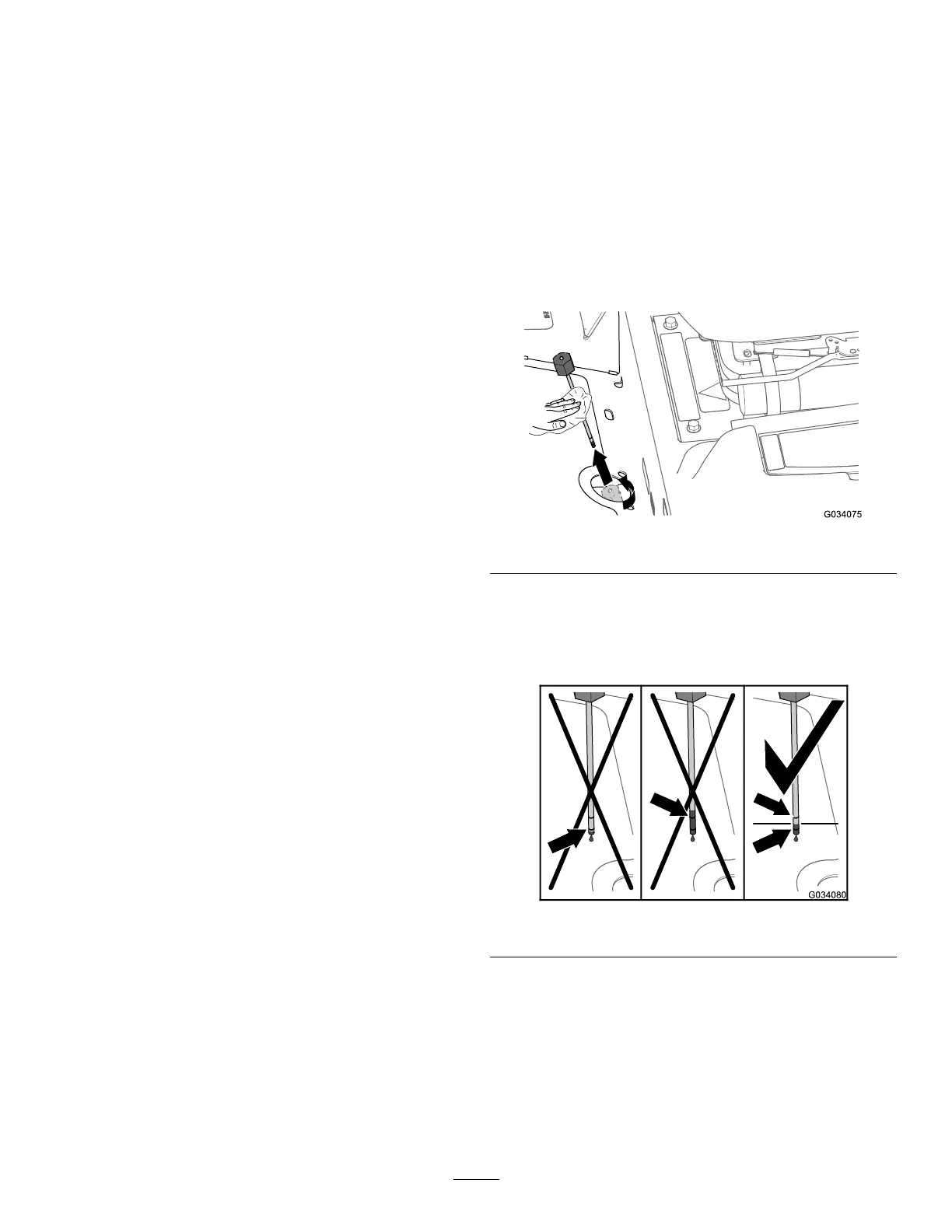

2.Loosendipstickcap(Figure78)andremovethe

dipstickfromtransaxlellertubeandwipethe

dipstickwithacleanrag.

g034075

Figure78

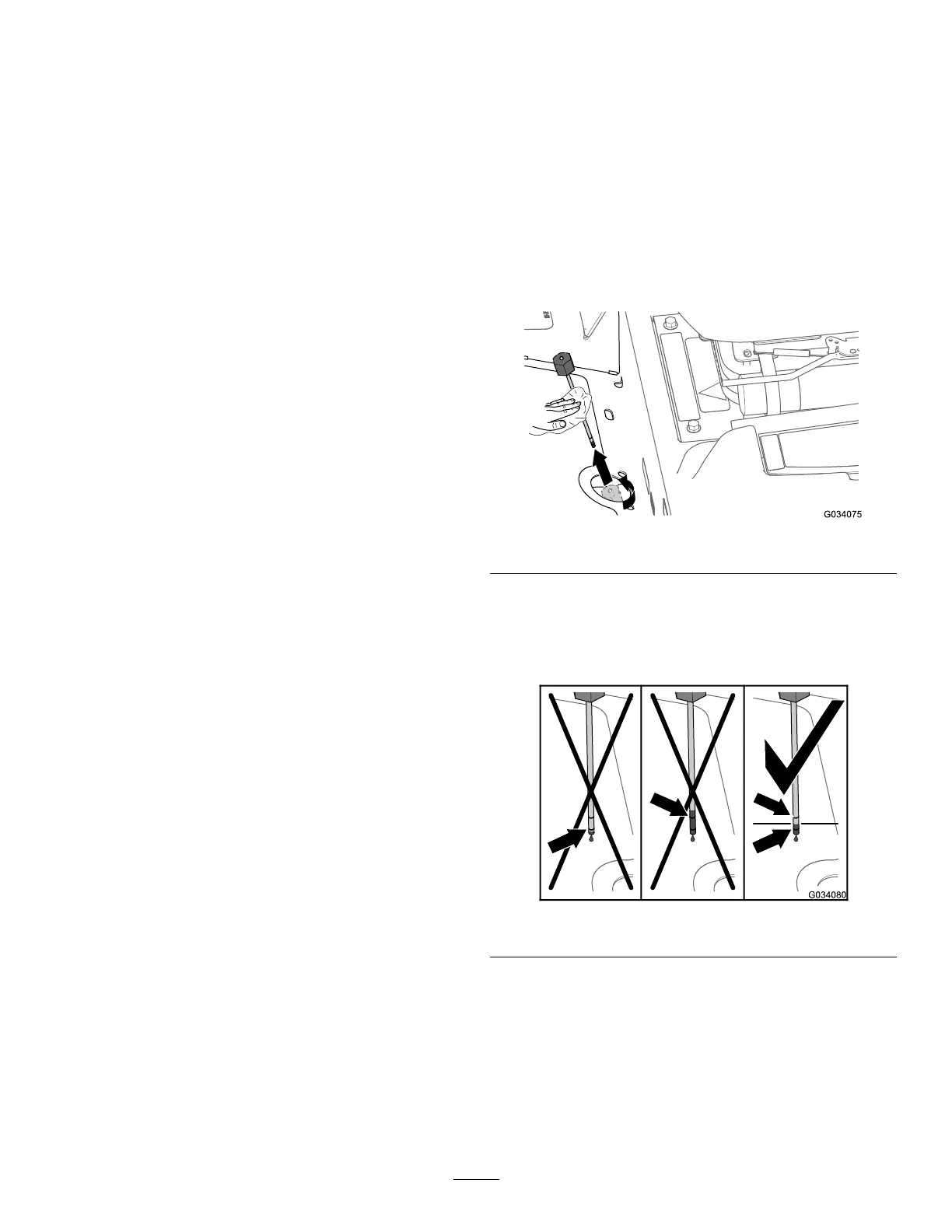

3.Insertthedipstickintothelltubeandthread

dipstickcapontothetube.

4.Removethedipstickandchecktheuidlevel

(Figure79).

g034080

Figure79

5.Iftheuidlevelisbelowthelowermarkofthe

dipstick,addthespeciedhydraulicuidintothe

lltube(Figure80)untiluidlevelrisesbetween

theupperandlowermarkswhencheckedwith

thedipstick(Figure79).

Important:Donotllthetransaxlehousing

withhydraulicuidabovetheuppermarkof

thedipstick.

64

Loading...

Loading...