24

Filling the Fuel Tank

Use only clean, fresh diesel fuel or biodiesel fuels with low

(<500 ppm) or ultra low (<15 ppm) sulfur content. The

minimum cetane rating should be 40. Purchase fuel in

quantities that can be used within 180 days to ensure fuel

freshness.

Fuel tank capacity: 6.5 U.S. gallons (25 l)

Use summer grade diesel fuel (No. 2–D) at temperatures

above 20 degrees F (–7 degrees C) and winter grade (No.

1–D or No. 1–D/2–D blend) below that temperature. Use of

winter grade fuel at lower temperatures provides lower

flash point and cold flow characteristics which will ease

starting and reduce fuel filter plugging.

Use of summer grade fuel above 20 degrees F (–7 degrees

C) will contribute toward longer fuel pump life and

increased power compared to winter grade fuel.

Danger

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A fire

or explosion from fuel can burn you and others

and can cause property damage.

• Use a funnel and fill the fuel tank outdoors, in

an open area, when the engine is off and is cold.

Wipe up any fuel that spills.

• Do not fill the fuel tank completely full. Add fuel

to the fuel tank until the level is 1/4 to 1/2 in. (6

to 13 mm) below the bottom of the filler neck.

This empty space in the tank allows the fuel to

expand.

• Never smoke when handling fuel, and stay away

from an open flame or where fuel fumes may be

ignited by a spark.

• Store fuel in a clean, sealed, safety-approved

container.

Biodiesel Ready

This machine can also use a biodiesel blended fuel of up to

B20 (20% biodiesel, 80% petrodiesel). The petrodiesel

portion should be low or ultra low sulfur. Observe the

following precautions:

• The biodiesel portion of the fuel must meet

specification ASTM D6751 or EN14214.

• The blended fuel composition should meet ASTM

D975 or EN590.

• Painted surfaces may be damaged by biodiesel blends.

• Use B5 (biodiesel content of 5%) or lesser blends in

cold weather

• Monitor seals, hoses, gaskets in contact with fuel as

they may be degraded over time.

• Fuel filter plugging may be expected for a time after

converting to biodiesel blends.

• Contact your distributor if you wish for more

information on biodiesel

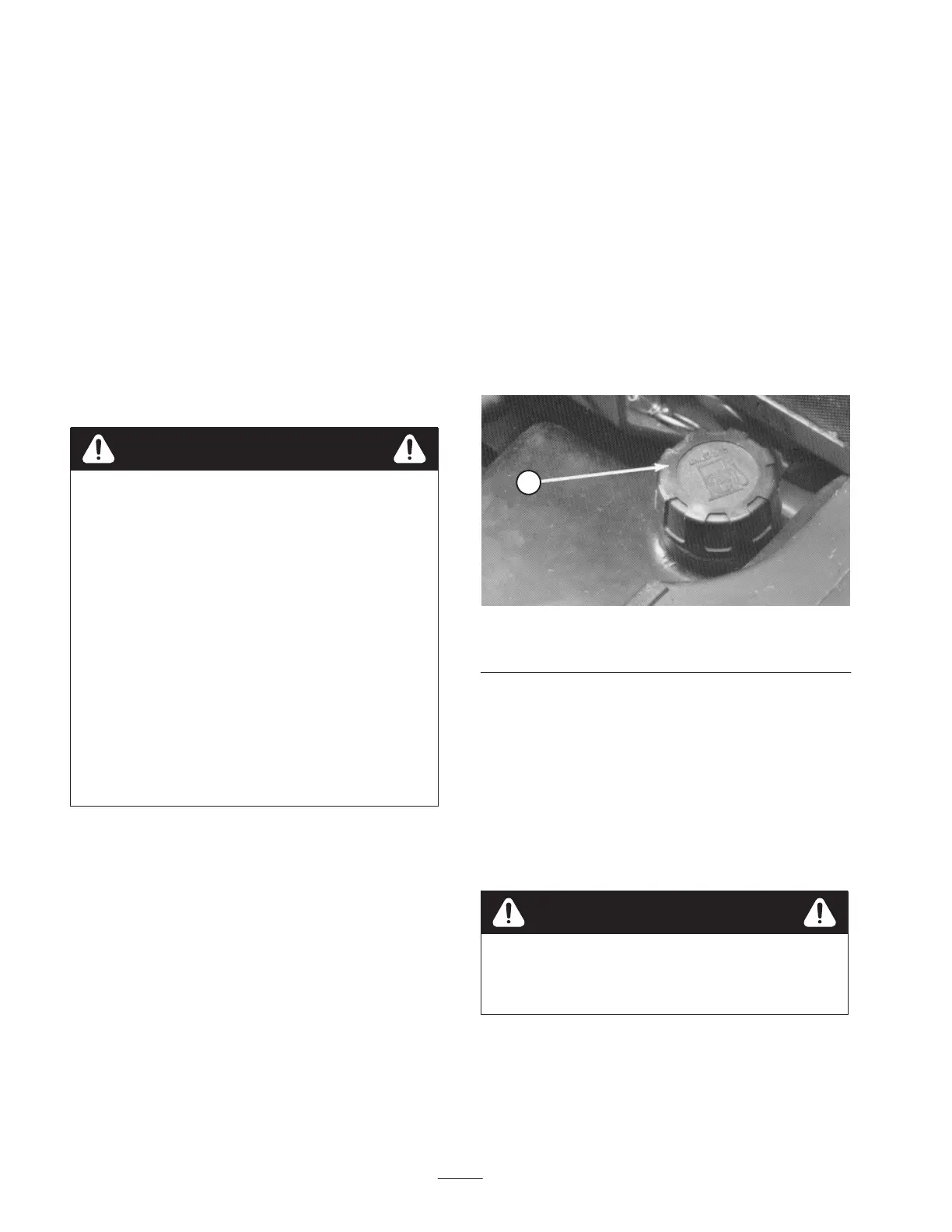

1. Tip seat forward and prop it with the support rod so it

cannot fall accidentally. Using a clean rag, clean area

around fuel tank cap (Fig. 23).

2. Remove cap from the fuel tank and fill the 6-1/2 gallon

(25 l) tank to within 1 in. (25 mm) from the top with

diesel fuel. Install fuel tank cap tightly after filling tank.

1

Figure 23

1. Fuel tank cap

Check Cooling System

Clean debris off screen and radiator/oil cooler daily, more

often if conditions are extremely dusty and dirty.

The cooling system is filled with a 50 / 50 solution of water

and permanent ethylene glycol anti–freeze. Check level of

coolant in expansion tank at beginning of each day before

starting the engine. Capacity of cooling system is 6 quarts

(5.6 l).

• If engine has been running, pressurized hot

coolant can escape when radiator cap is

removed and cause burns.

Caution

1. Check level of coolant in expansion tank. Coolant level

should be between the marks on side of tank.

Loading...

Loading...