Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyourengineowner’smanual

foradditionalmaintenanceprocedures.

Note:Downloadafreecopyoftheelectricalor

hydraulicschematicbyvisitingwww.T oro.comand

searchingforyourmachinefromtheManualslinkon

thehomepage.

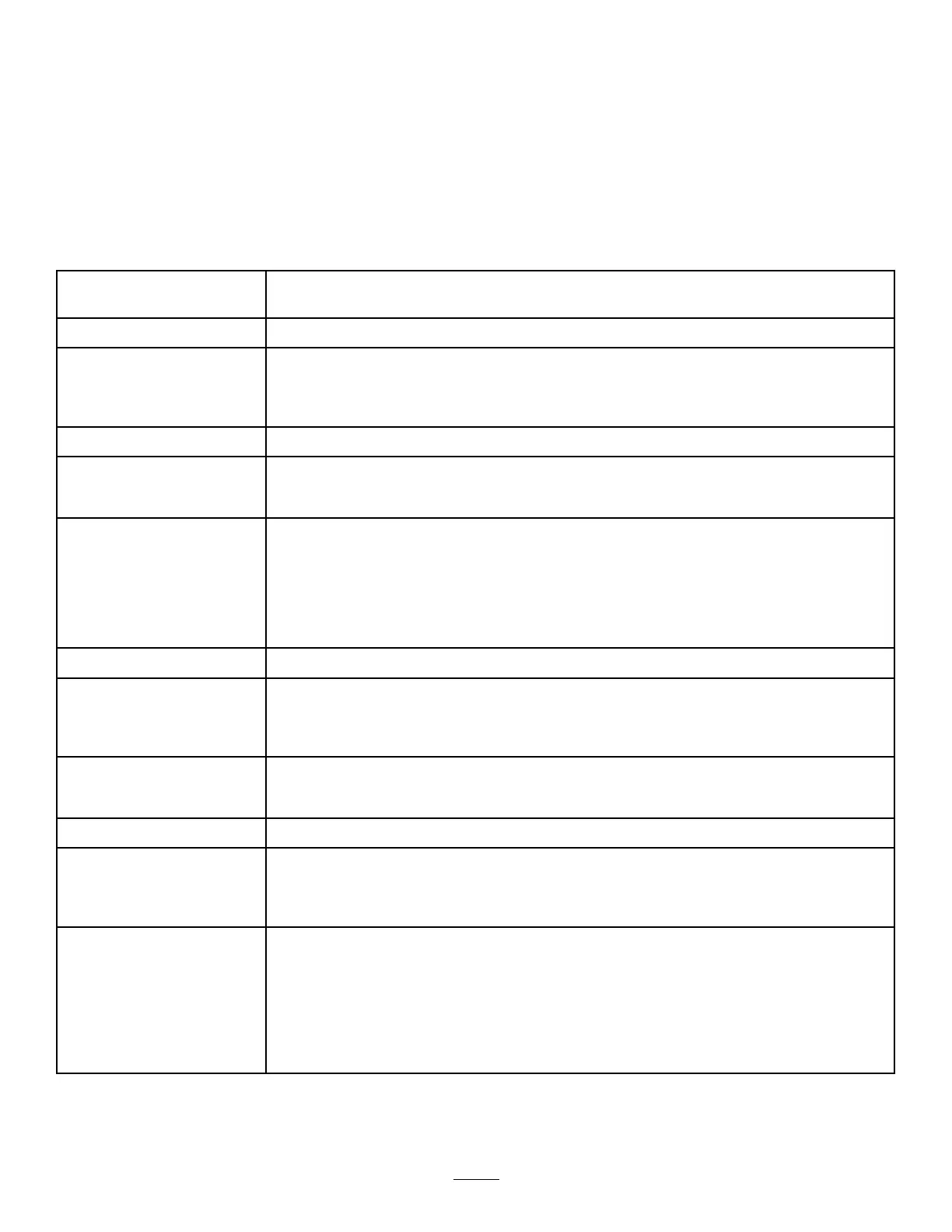

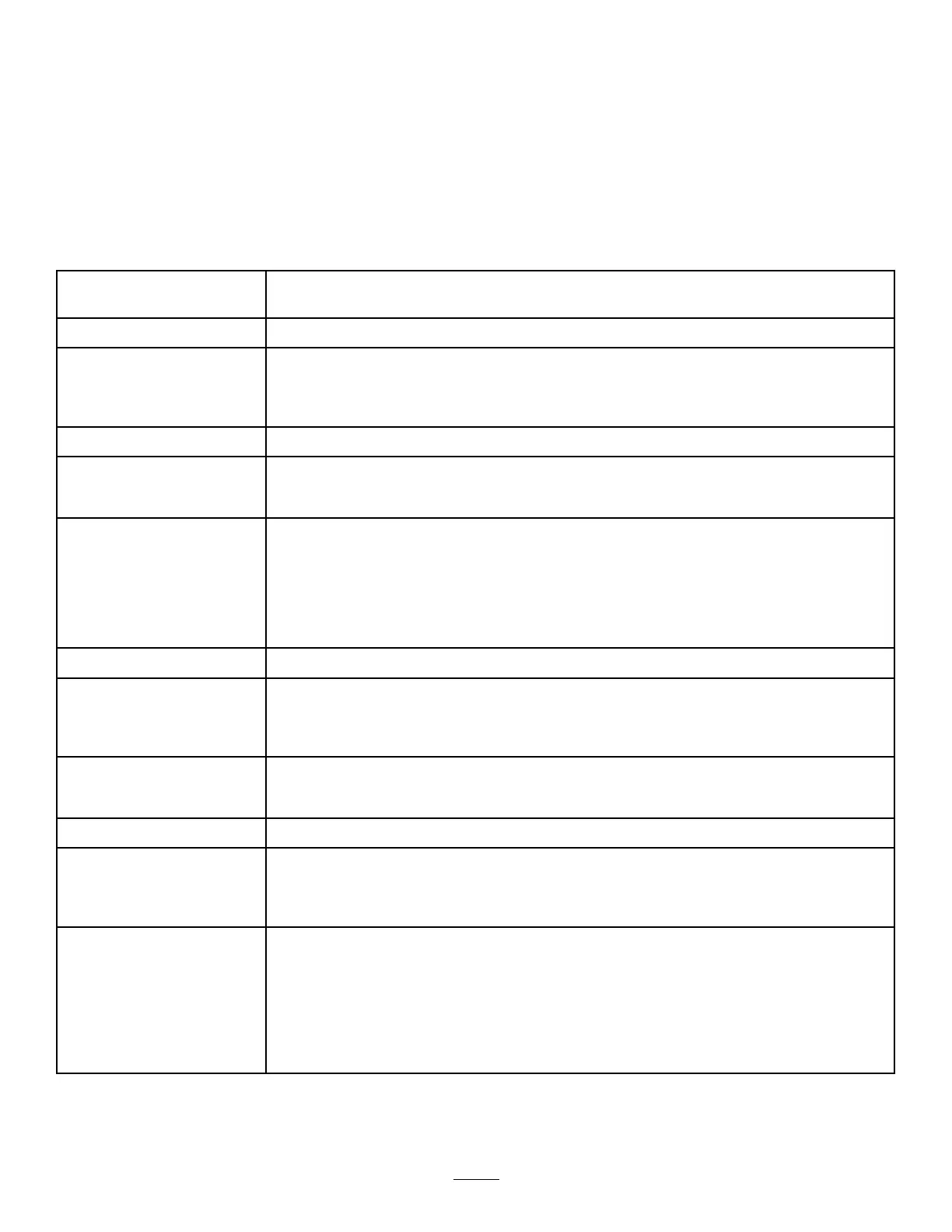

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Afterthersthour

•Torquethewheellugnuts.

Aftertherst10hours

•Torquethewheellugnuts.

•Checkthealternator-belttension.

•Checkthecompressorbelttension.

•Checktheblade-drive-belttension.

Aftertherst50hours

•Changetheengineoilandlter.

Aftertherst200hours

•Changethefrontplanetary-gearoil.

•Changetherear-axlelubricant.

•Changethehydrauliclters.

Beforeeachuseordaily

•Checkthetirepressure.

•Checkthesafety-interlockswitches.

•Checktheengine-oillevel.

•Checktheair-cleanerindicator

•Drainwaterorothercontaminantsfromthewaterseparator.

•Checkthecoolantlevel.

•Checkthehydraulic-uidlevel.

Every25hours

•Checktheelectrolytelevel(orevery30daysifthemachineisinstorage).

Every50hours

•Lubricateallbearingsandbushings.

•Inspecttheaircleaner.

•Checktheconditionofthebattery.

•Checktheblade-drive-belttension.

Every100hours

•Inspectthecooling-systemhosesandclamps.

•Checkthealternator-belttension.

•Checkthecompressorbelttension.

Every200hours

•Torquethewheellugnuts.

Every250hours

•Changetheengineoilandlter.

•Cleanthecabairlters;replacethemiftheyaretornorexcessivelydirty.

•Cleantheair-conditioningcoil.(Cleanmorefrequentlyinextremelydustyordirty

conditions)

Every400hours

•Servicetheaircleaner(earlieriftheaircleanerindicatorshowsred,andmore

frequentlyinextremelydirtyordustyconditions).

•Inspectthefuellinesandconnections.

•Replacetheltercanister.

•Checktheplanetary-gear-driveoil(checkifyounoticeexternalleakage).

•Checkforend-playintheplanetarydrives.

•Checktherear-axlelubricant.

•Checktherear-axle-gearboxlubricant.

56

Loading...

Loading...