19

Note: The injection operation starts approximately 4–5

seconds after the pump engages. Also, the injection system

will automatically stop if the traction bail is not engaged

within 3–4 seconds after starting the water system.

11. When aerating, work moving perpendicular from the

water supply to avoid running over the garden hose.

Use the front edge of the hood or rear corner of the

frame to align rows, if desired. When at the end of a

row, make an “S” maneuver and reverse the direction of

the aerator. Do not make sharp turns on a green or

scuffing from the tire may occur. Always maintain

awareness of what lies ahead in the direction of forward

travel.

12. Regulate the roller spray wash, if required, to remove

debris from the rollers.

Note: A small amount of water from the regulator bypass

may come out of the spray wash nozzles even with the

spray wash in the “OFF” position.

13. In areas where greater hole depth or more frequent

holes are desired, the engage button can be held down

to allow multiple shots while machine is stopped.

Important Hole depths can reach 20 inches or more

when making multiple shots, so be aware of what is buried

below the turf. Also, an excessive amount of holes and

muddy turf conditions may occur when making multiple

shots.

14. To stop water injection, press the red button. The

system continues for a few seconds after the button is

pressed. Raise the machine to the transport position,

disconnect the supply hose, and move to the next

location.

Checking the Interlock System

If safety interlock switches are disconnected or

damaged the machine could operate unexpectedly,

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

• Replace switches every two years regardless of

whether they are operating properly or not.

Caution

The purpose of the safety interlock system is to prevent the

engine from cranking or starting unless the traction bail is

in NEUTRAL and prevents the water system from

engaging if the machine is in the transport (raised) position.

It also stops aeration if the traction bail is released while

operating or if the machine is raised to the transport

position.

To do a functional check of interlock system:

1. Position the machine in a flat, open area on rough turf

and away from buried wires, plumbing, etc. Stop the

engine.

2. Move the traction bail up and down while trying to start

the engine. If the engine cranks, there is a malfunction

in the interlock system that must be corrected. If the

engine does not crank, proceed to step 3.

3. Connect the water supply to the machine. Turn on the

water supply and bleed all air out of the system. The

water pressure must be 30 psi or more. Start the engine.

Raise the machine to the transport position (up off the

rollers). Push the aerate ENGAGE button. If the water

pump engages and the machine begins aerating, there is

a malfunction in the interlock system that must be

corrected. If the machine does not begin aerating,

proceed to step 4.

4. Lower the machine to the aerate position (on the

rollers). Engage the traction bail to start the machine

moving. Push, then release the aerate ENGAGE button.

The water pump should engage immediately, then the

machine should begin aerating 5 seconds after the pump

engages. Release the traction bail to the neutral position

so that the machine stops moving. The water pump

should disengage 4 seconds after the traction bail

returns to neutral, then stop aerating after another 3

seconds. If the machine does not stop aerating when the

traction bail returns to neutral, there is a malfunction in

the interlock system that must be corrected. If the

machine stops aerating, proceed to step 5.

5. Engage the traction bail to start the machine moving,

then push the aerate ENGAGE button to begin aerating.

Push the aerate DISENGAGE button. The water pump

should disengage immediately, then stop aerating after 3

seconds. If the machine does not stop aerating, there is a

malfunction in the interlock system that must be

corrected.

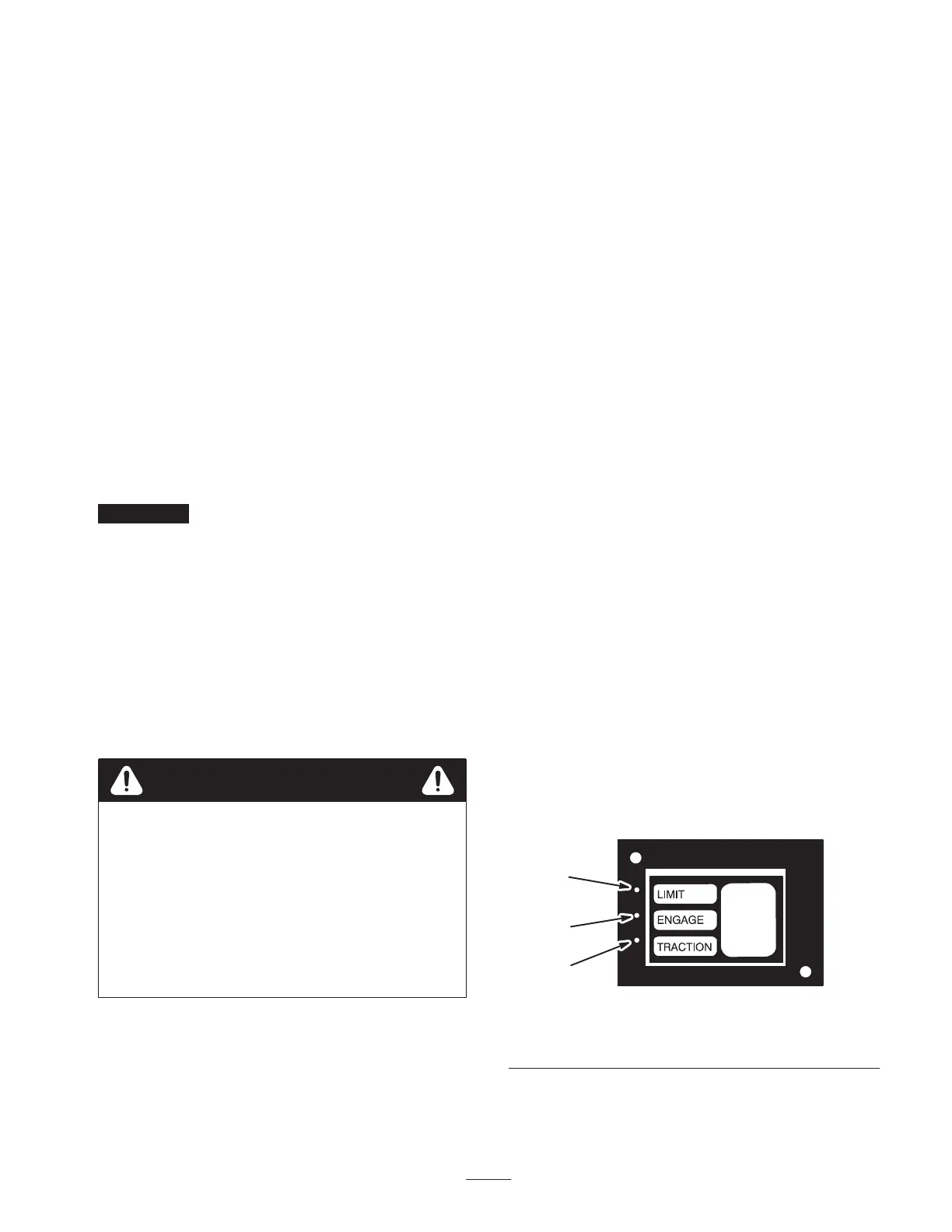

Note: Lights (LED’s) on the controller (Fig. 13) indicate

when the following inputs are made to the controller:

1

2

3

Figure 13

1. Red light

2. Green light

3. Yellow light

Red: Transport switch closed (traction bail in neutral)

Loading...

Loading...