21

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

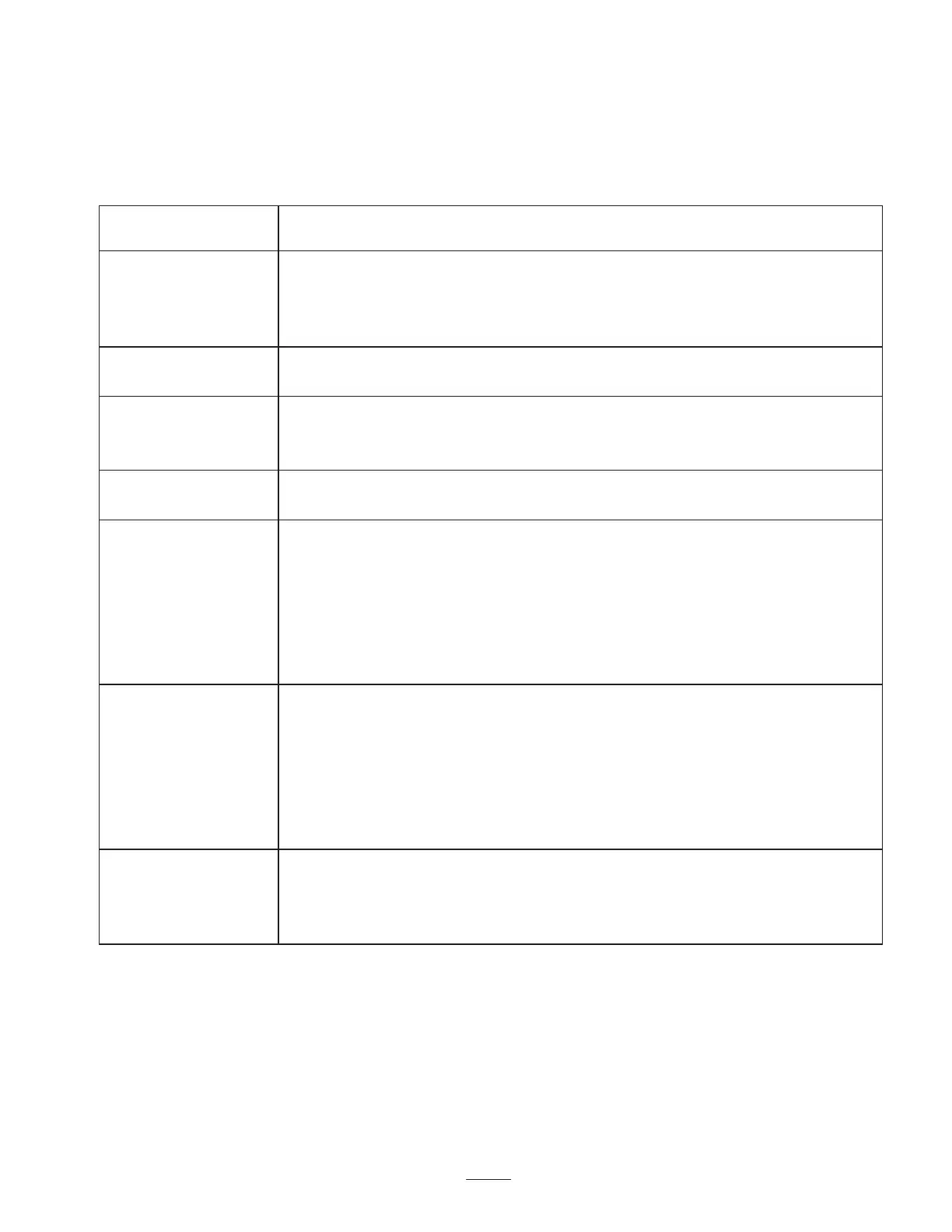

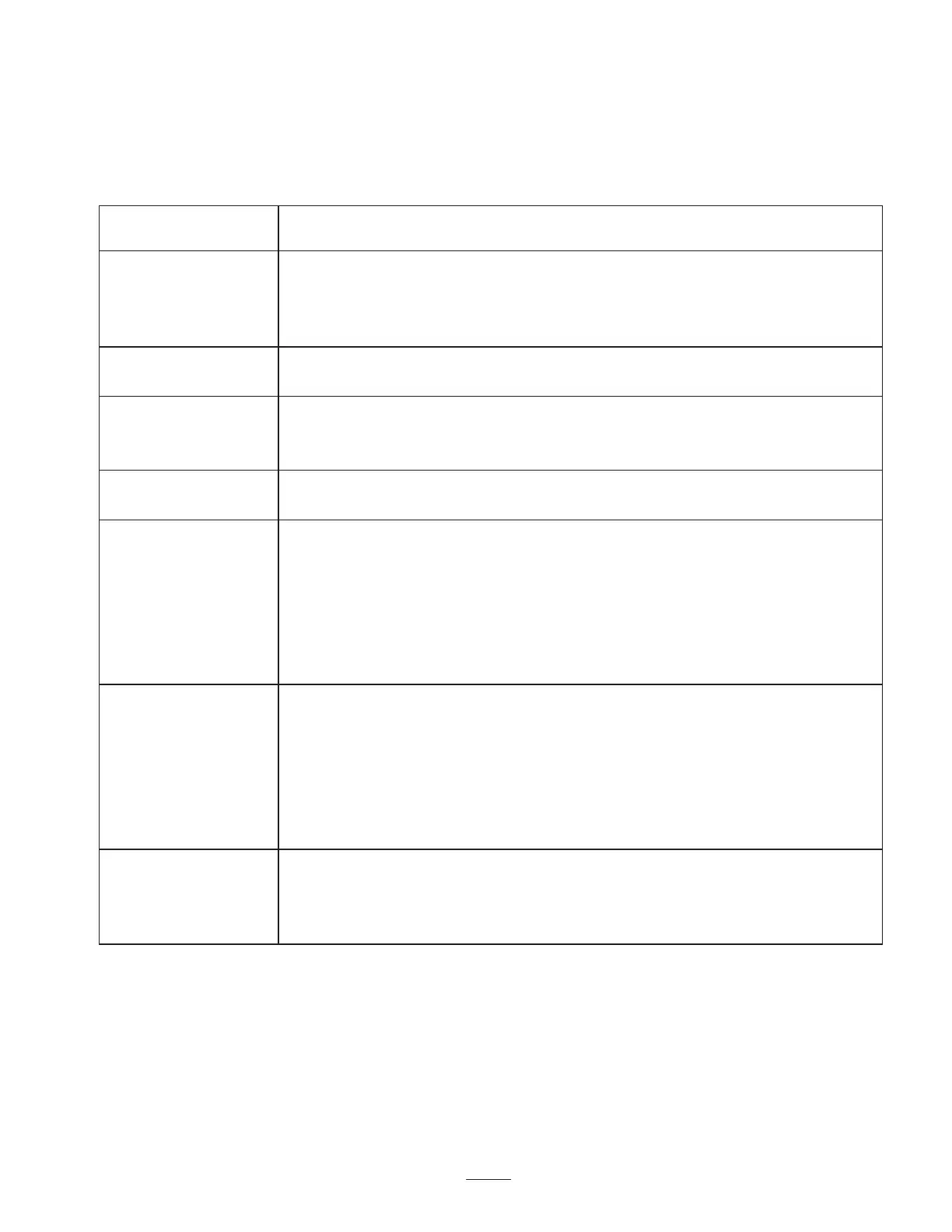

Recommended Maintenance Schedule

Maintenance Service

Interval

Maintenance Procedure

After first 25 hours

• Change the engine oil and filter.

• Change the gear case oil and filter.

• Change the pump case oil.

• Torque the wheel lug nuts.

After first 50 hours

• Torque head and adjust the valves.

• Check the engine RPM (idle and full throttle).

Every 50 hours

• Check the battery fluid level.

• Check the battery cable connections.

• Lubricate all grease fittings.

Every 100 hours

• Change the engine oil and filter.

• Change the engine pre-cleaner (air filter).

Every 200 hours

• Replace the air filter element.

• Replace the fuel filter.

• Adjust the water system cam—valve clearance.

• Clean the engine crankcase breather.

• Change the gear case oil and filter.

• Change the pump case oil.

• Torque the wheel lug nuts.

Every 400 hours

• Adjust the parking brake.

• Calibrate the aeration traction speed.

• Service the injector nozzles and springs.

• Replace the spark plugs.

• Decarbon the combustion chambers.

• Torque head and adjust the valves.

• Check the engine RPM (idle and full throttle).

Every 1000 hours or 2

years, whichever occurs

first

• Replace moving hoses.

• Replace safety switches.

• Drain and flush the fuel tank.

• Drain and flush the hydraulic tank.

Water System Accumulator

Due to the operational requirements of the accumulator design, the high pressure internal gas pre–charge can bleed out during

periods of inactivity. Storing the Hydroject for extended periods of time (3 months or longer) and/or seasonal temperature

variances can affect the accumulators ability to retain a sufficient pre–charge and seasonal servicing (recharge) may be

required.

If one of the accumulator charge indicator lamps illuminates, contact your authorized Toro Distributor for accumulator

maintenance services.

Loading...

Loading...