28

5. After setting the air gap at .025 in., install the spark

plugs in the cylinder head. Tighten the plugs to

10–15 ft.-lb. (14–20 N⋅m). Push the wires onto the

spark plugs.

6. Lower the hood and secure the latches.

Cleaning the Cylinder Head

Fins

To avoid overheating and possible engine damage, clean

the cooling fins on the cylinder head every day if necessary.

1. Disengage the hood latches and open the hood.

2. Pull the wires off of the spark plugs.

3. Clean dirt, grass, and chaff from the outside of the

cylinder, the cylinder head fins, and the air intake

screen.

4. Push the wires onto the spark plugs.

5. Lower the hood and secure the latches.

Changing the Gear Case Oil

and Filter

Change the hydraulic oil and filter initially after 25 hours of

operation; thereafter change them every 200 hours of

operation.

Important The gear case oil and filter must be changed

immediately when any contamination, sludge, water or

condensation appears.

1. Disengage the hood latches and open the hood.

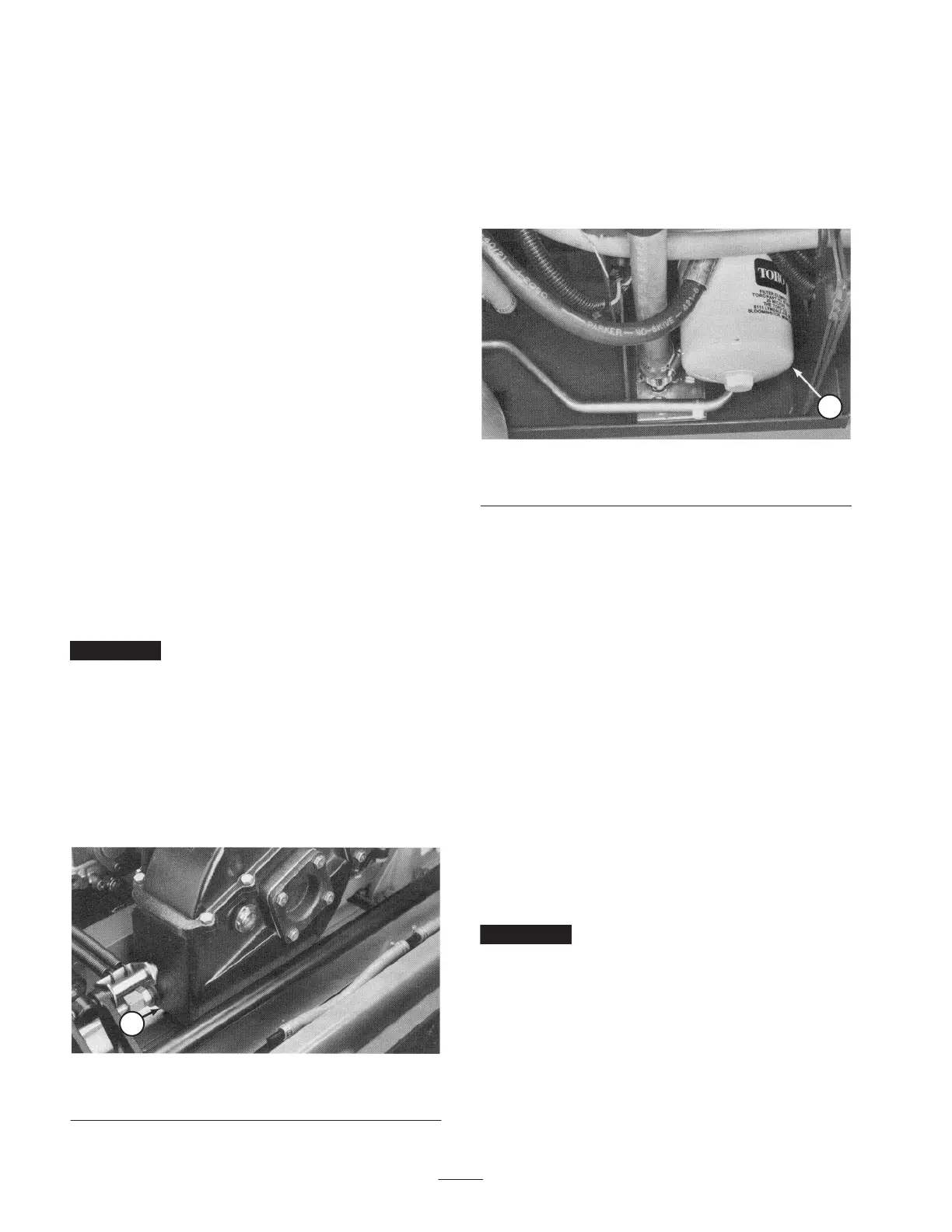

2. Place a drain pan under the bottom of the gear case.

Clean the area around the drain plug (Fig. 28).

Note: When draining the oil, use a funnel or some type of

channel to divert the draining oil away from the machine

components and into a drain pan.

1

Figure 28

1. Drain plug location

3. Remove the drain plug and allow the oil to flow into a

drain pan. After the oil has drained, install the oil drain

plug.

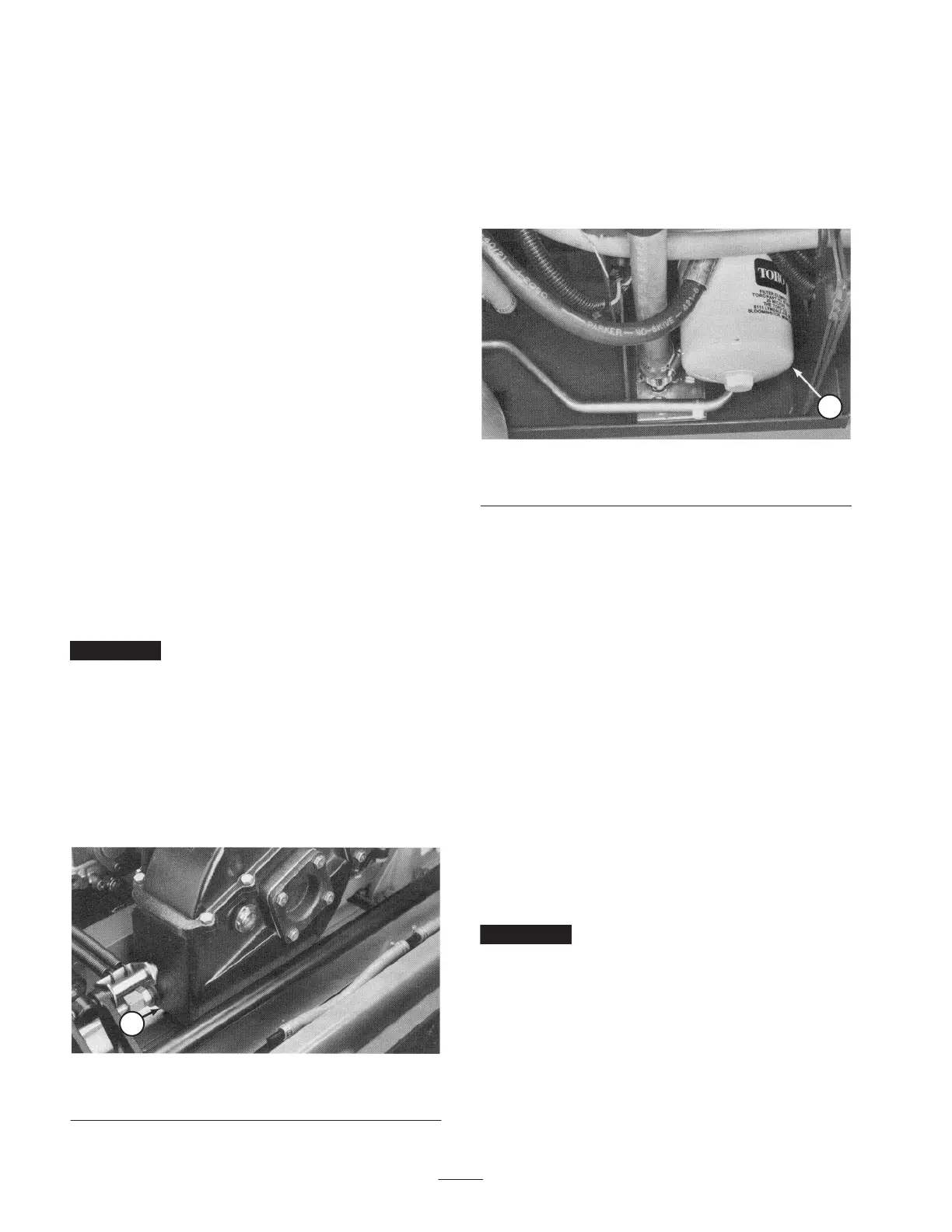

4. Remove the oil filter (Fig. 29), mounted below control

panel base, and discard the filter. Thoroughly clean the

filter mounting surface and make sure that a new gasket

is installed in the new filter.

1

Figure 29

1. Oil filter

5. Fill the new filter with new Mobil DTE 26 hydraulic oil

or equivalent oil (refer to Fluid Recommendations,

page 10). Apply a thin film of clean oil to the filter

gasket.

6. Install the new filter by hand until the gasket just

touches the mounting surface, then turn it an additional

1/2 to 3/4 turn.

7. Remove the filler cap and add approximately 4–5 quarts

of Mobil DTE 26 hydraulic oil or equivalent oil (refer

to Fluid Recommendations, page 10) to the gear case

reservoir. Install the filler cap.

8. Check for leaks around the oil filter. Tighten the filter

only enough to eliminate leaks. Do not overtighten.

9. Lower the hood and secure the latches.

Changing the Pump Case Oil

Change the pump oil initially after 25 hours of operation;

thereafter change it every 200 hours of operation.

Important The pump case oil must be changed

immediately when any contamination, sludge, water or

condensation appears.

1. Disengage the hood latches and open the hood.

2. Place a drain pan under the pump case. Clean the area

around the drain plug on the bottom of the case

(Fig. 30).

Note: When draining the oil, use a funnel or some type of

channel to divert the draining oil away from the machine

components and into a drain pan.

Loading...

Loading...