29

1

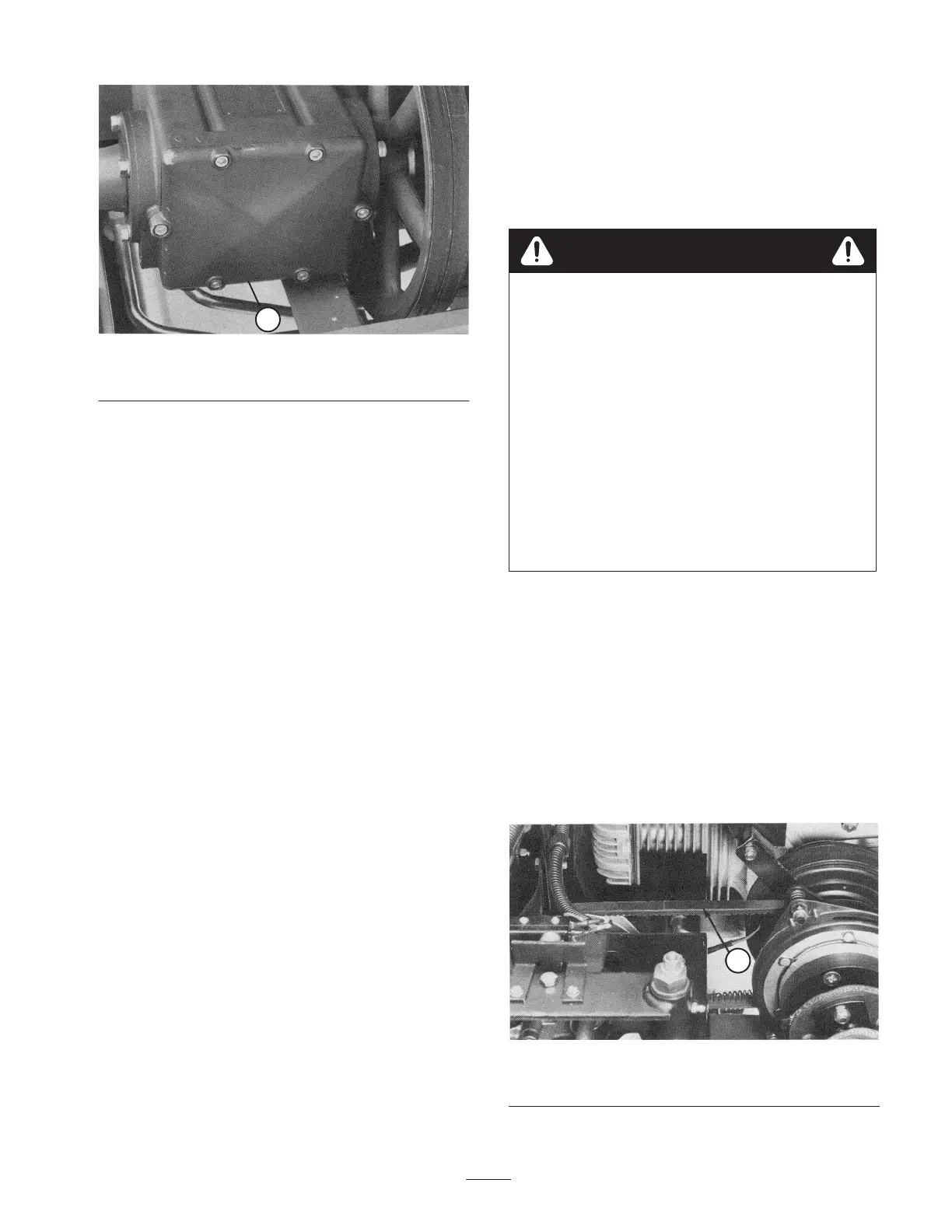

Figure 30

1. Drain plug location

3. Remove the drain plug and allow oil to flow into a drain

pan. After the oil has drained, install the oil drain plug.

4. Remove the dipstick/filler cap and add approximately

40 ounces of Mobil DTE Extra Heavy oil or equivalent

oil (refer to Fluid Recommendations, page 10) to the

pump case. Install the filler cap.

5. Check the oil level. If the fluid level is low, add enough

Mobil DTE Extra Heavy oil or equivalent to bring the

oil up to the proper level. Do not overfill.

6. Check for possible leaks. Lower the hood and secure

the latches.

Checking the Hydraulic Lines

and Hoses

Check the hydraulic lines and hoses daily for leaks, kinked

lines, loose mounting supports, wear, loose fittings, weather

deterioration, and chemical deterioration. Make all

necessary repairs before operating.

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

• Make sure all hydraulic fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

• Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic leaks.

• Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

• Get immediate medical help if fluid is injected

into skin.

Warning

Adjusting the Traction Pump

Belt

Make sure that the traction pump belt is properly tensioned

to ensure correct operation of the unit and unnecessary

wear. Check the belt midway in the span of the belt.

1. Disengage the hood latches and open the hood.

2. Check the belt tension by depressing the belt midway

between the pulleys with 3 lb. of force. The belt should

deflect 9/64 in. (Fig. 31).

1

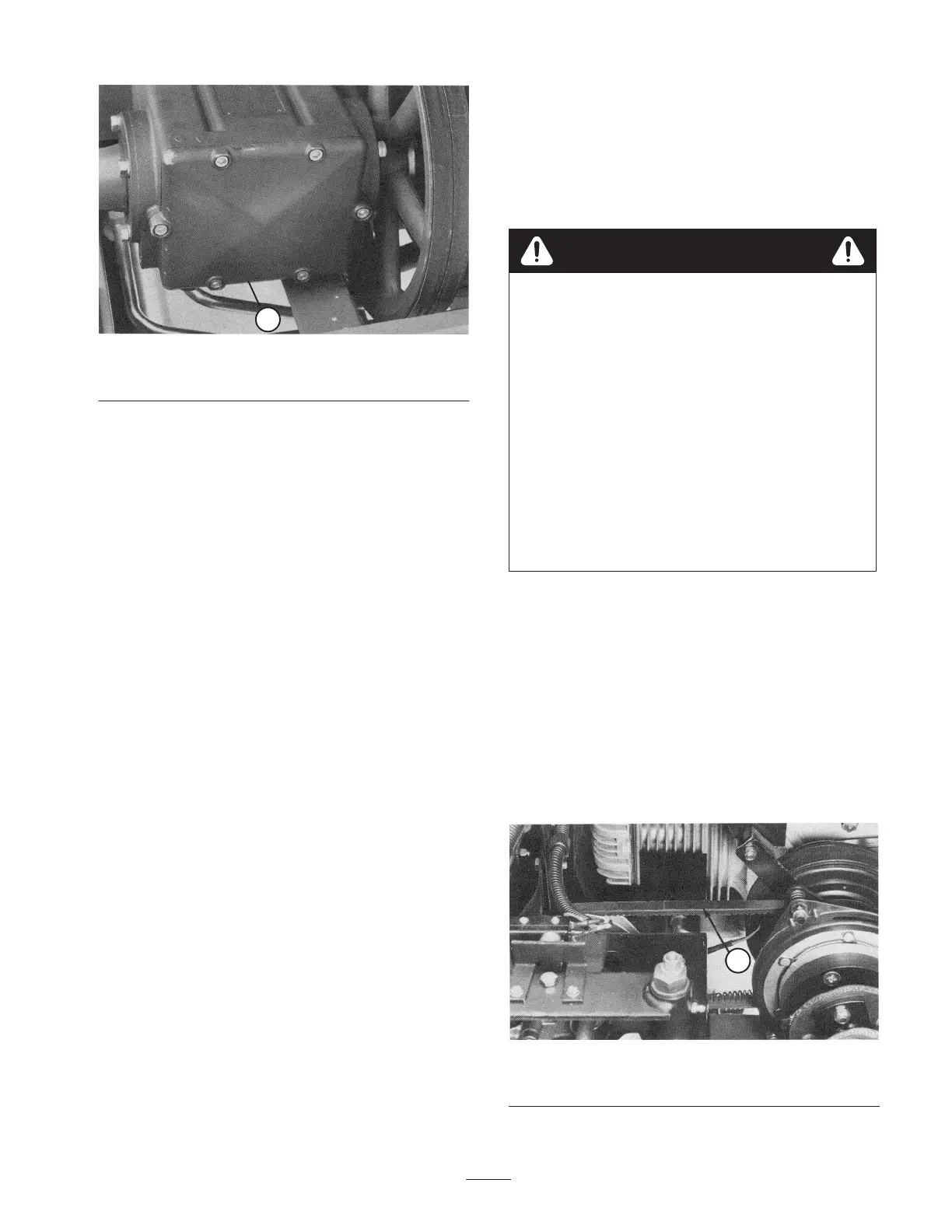

Figure 31

1. Traction pump belt

Loading...

Loading...