Note 1: Criteria for the difference between suction and discharge temperatures

(1) Cooling operation

After operating for a minimum of 30 minutes in “COOL” mode, if the T dry bulb temperature difference

between suction and discharge air of the indoor unit is 8°C or more, it is normal.

(2) Heating operation

After operating for a minimum of 30 minutes in “HEAT” mode, if the T dry bulb temperature difference

between suction and discharge air of the indoor unit is 15°C or more, it is normal.

* If demand from the indoor unit on the outdoor unit is low because the difference between the temperature

set by the remote controller and the temperature of the room is small, then the T temperature difference is

small.

* Consider that T temperature difference may diminish in cases of a system in which the connected indoor

unit capacity exceeds the outdoor unit capacity, the pipe length is long, or a large difference exists among

outdoor units.

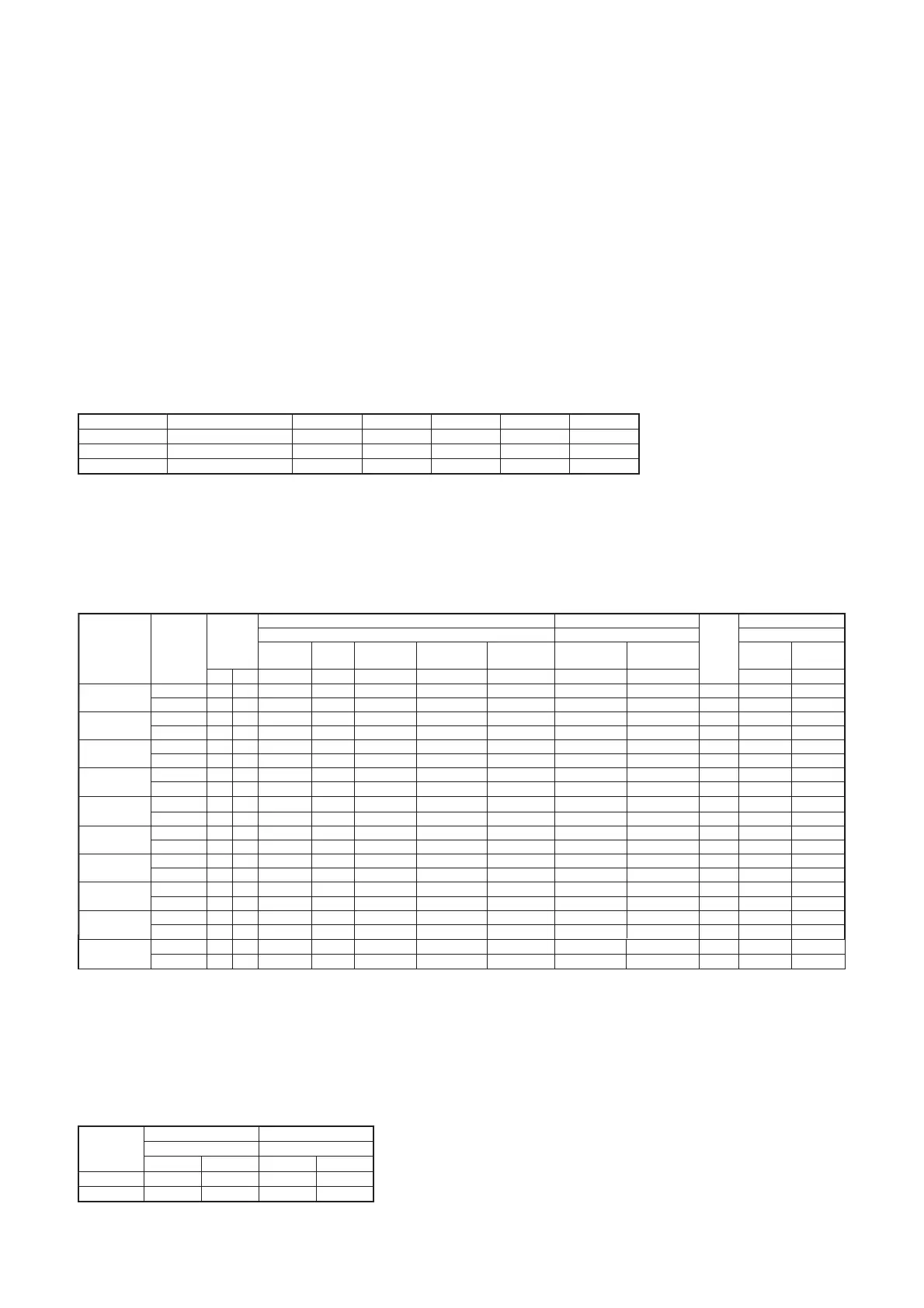

Note 2: Criteria for operating power current

The table below shows the maximum current for each outdoor unit. Under standard conditions, operating

current is about 80% of the value shown in the table below.

Model

Current value

Model

Current value

MMY-MUP

(A)

MMY-MUP

(A)

0801*

15.4

14A1*

27.0

1001*

20.5

1801*

34

1201*

24.5

2001*

36

1401*

27.5

2201*

51

2401*

54

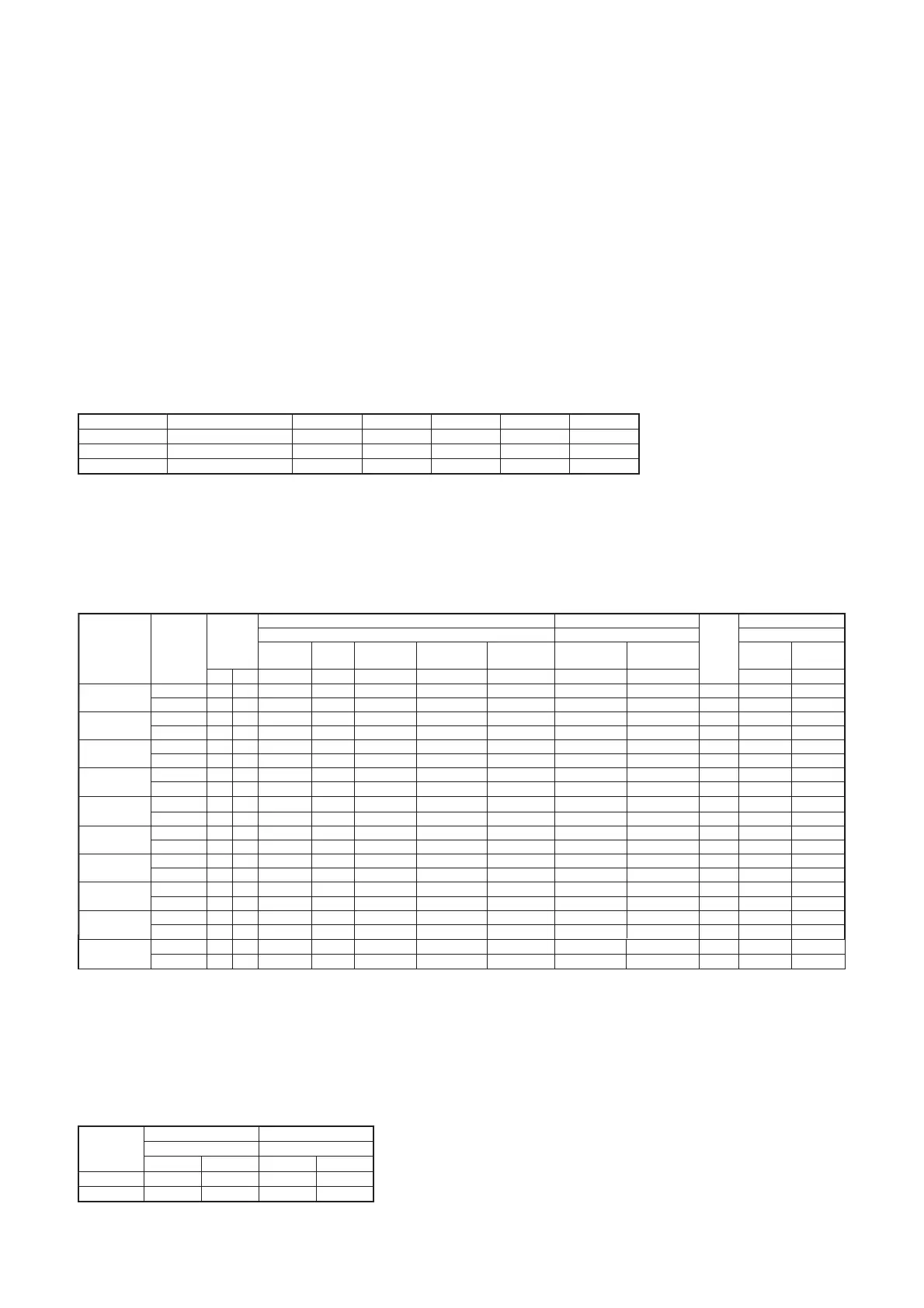

Note 3: Criteria for cycle status

(1) These data are based on operating a 4-way Air Discharge Cassette type air conditioner of 100%

connection with standard piping length.

Data may vary depending on temperature conditions, installed pipe length, and room shape combinations,

or indoor unit connection capacity.

For pressure criteria in different temperature conditions, refer to (2).

* This compressor is driven with a 6-pole motor. The value of the compressor frequency (rps) measured with a

clamp meter at the compressor lead line is three times the rotation count (rps) of the compressor

.

* Each compressor may have a different frequency as a measure against resonance.

* The temperature of the indoor heat exchanger (TC) indicates TCJ sensor temperature when cooling, and

TC2 sensor temperature when heating, respectively.

Operating

Mode

Pressure

(MPa)

Temperature

㧔

ºC

㧕

Indoor

18 ~ 32

15 ~ 32

PS

0.5 ~ 0.9

0.5 ~ 0.7

Pd

2.0 ~ 3.3

2.5 ~ 3.3

Cooling

Heating

Outdoor

25 ~ 35

5 ~ 35

(2) Criteria for operating pressure

* Criteria after 14 minutes or more has passed since operating started

1601*

30.5

Pipe Surface Temperature Compressor Rotation Air Temperature

Outdoor

Pressure

(ºC) (rps) (DB/WB)(ºC)

Unit

Operating

(MPa)

Indoor

Indoor Heat Outdoor Heat Liquid

MMY-MUP

Mode

Discharge Suction

Exchanger Exchanger Temperature

Compressor 1 Compressor 2

Fan

Outdoor Indoor

Pd

Ps

TD1

TS1

TC2

TE1 TL3

Cmp. 1

Cmp. 2 TO

TA

Cooling

3.0

1.0

79

21

15

39 26

50

High

35

27

0801*

Heating

2.4

0.7

67

2

25

1 21

57

High

7

20

Cooling

3.1

1.0

82

21

15

40 26

56

High

35

27

1001*

Heating

2.8

0.7

79

2

23

0 17

63

High

7

20

Cooling

3.4

1.1

86

21

15

40 29

65

High

35

27

1201*

Heating

2.5

0.7

75

1

25

0 16

75

High

7

20

Cooling

3.7

1.1

91

20

16

41 33

77

High

35

28

1401*

Heating

2.4

0.7

73

1

26

-1

22

83

High

7

20

Cooling

3.1

1.0

81

19

15

41 33

77

High

27

14A1*

35

Heating

2.5

0.7

73

1

26

-1

22

83

High

7

20

1601*

Cooling

3.2

1.0

85

19

15 43

28

65

High

35

27

Heating

2.5

0.6

71

-1

27 1

17

68

High

7 20

1801*

Cooling

3.4

1.0

90

19

14 42

28

70

High

35 27

Heating

2.5

0.6

72

-2

27 2

22

77

High

7 20

2001*

Cooling

3.3

0.9

92

20

14 43

31

77

High

35 27

Heating

2.5

0.6

79

0

25 0

1

82

High

7

20

2201*

Cooling

3.5

1.0

94

27

15 42

29

71 70

High

35

27

Heating

2.7

0.6

82

-1

25 0

-4

79 77

High

7

20

2401*

Cooling

3.7

1.0

98

21

15 43

30

78 77

High

35

27

Heating

2.6

0.6

81

-1

24 0

20

79 77

High

7

20

―

―

―

―

―

―

―

―

―

―

―

―

―

―

Loading...

Loading...