Controls Interface

RTAC-SVX01J-EN 11 5

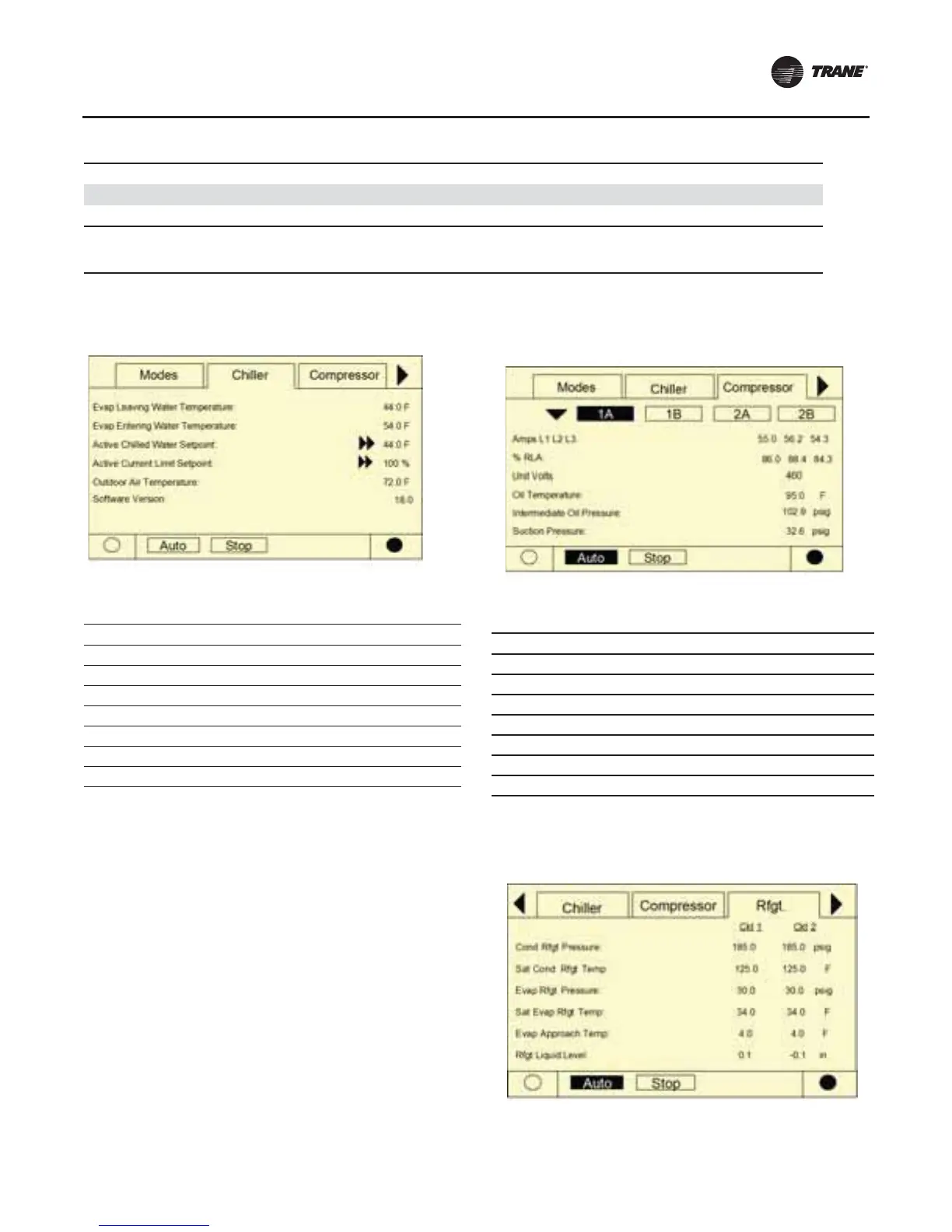

Chiller Screen

The chiller screen is a summary of the chiller activity.

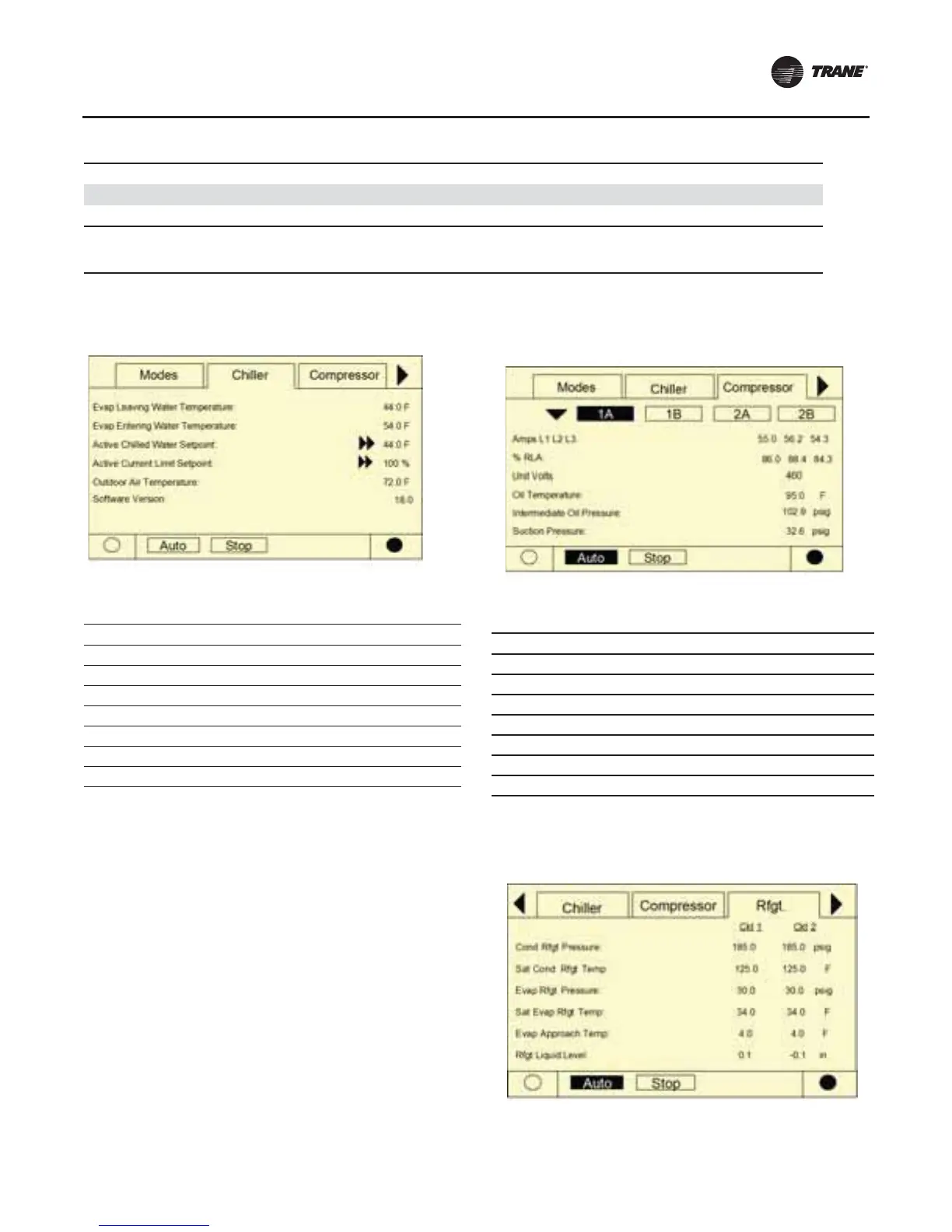

Compressor Screen

The compressor screen displays information for the one,

two, three, or four compressors in the format shown.The

top line of radio buttons allows you to select the

compressor of interest.The next three lines show the

compressor operating mode.The compressor radio

buttons and the compressor operating mode lines don’t

change as you scroll down in the menu.

The top screen has no upward scroll keys.The single arrow

down

scrolls the screen one line at a time. As soon as the

display is one line away from the top, the upward pointing

arrow appears.

The last screen has a single arrow to scroll upward one line

at

a time.When in the last position, the single down arrow

disappears.

Each compressor has its own screen depending on which

radio

key is pressed. When toggling between compressor

screens, say to compare starts and run time, the same lines

can be seen without additional key strokes. For example,

toggling from the bottom of the compressor 1A menu

accesses the top of the compressor 2A menu.

.

Refrigerant Screen

The refrigerant screen displays those aspects of the chiller

related to the refrigerant circuits.

Service Tool Lockout

The compressor is in the process of shutdown due to a command from the TechView

Service T

ool to be "locked out" and inoperative. This setting is nonvolatile and operation

can only be restored by using TechView to "unlock" it.

Table 56. Compressor modes (continued)

Compressor Modes Description

Top Level Mode

Sub-modes

Table 57. Chiller screen

Description Resolution Units

Evap Leaving Water Temperature X.X F / C

Evap Entering Water Temperature X.X F / C

Active Chilled Water Setpoint X.X F / C

Active Current Limit Setpoint X % RLA

Out Door Temperature X.X F / C

Software Type RTA Text

Software Version X.XX Text

Table 58. Compressor screen

Description Resolution Units

Amps L1 L2 L3 XXX Amps

% RLA L1 L2 L3 X.X % RLA

Unit Volts XXX Volts

Oil Temperature X.X F / C

Intermediate Oil Pressure X.X Pressure

Suction Pressure X.X Pressure

Starts/ Run Hours X, XX:XX hr:min

Loading...

Loading...