Installation - Mechanical

52 RTAC-SVX01J-EN

Water Pressure Gauges

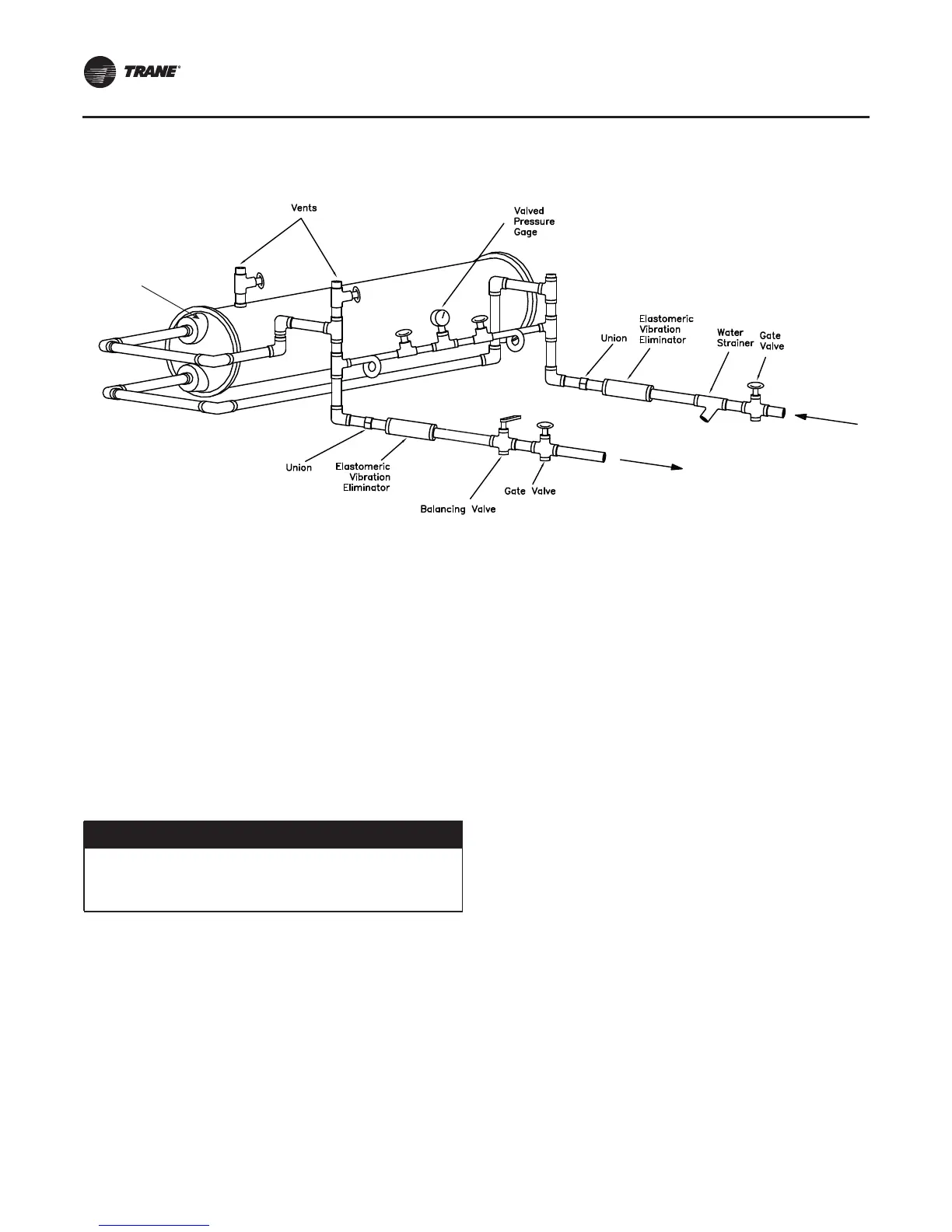

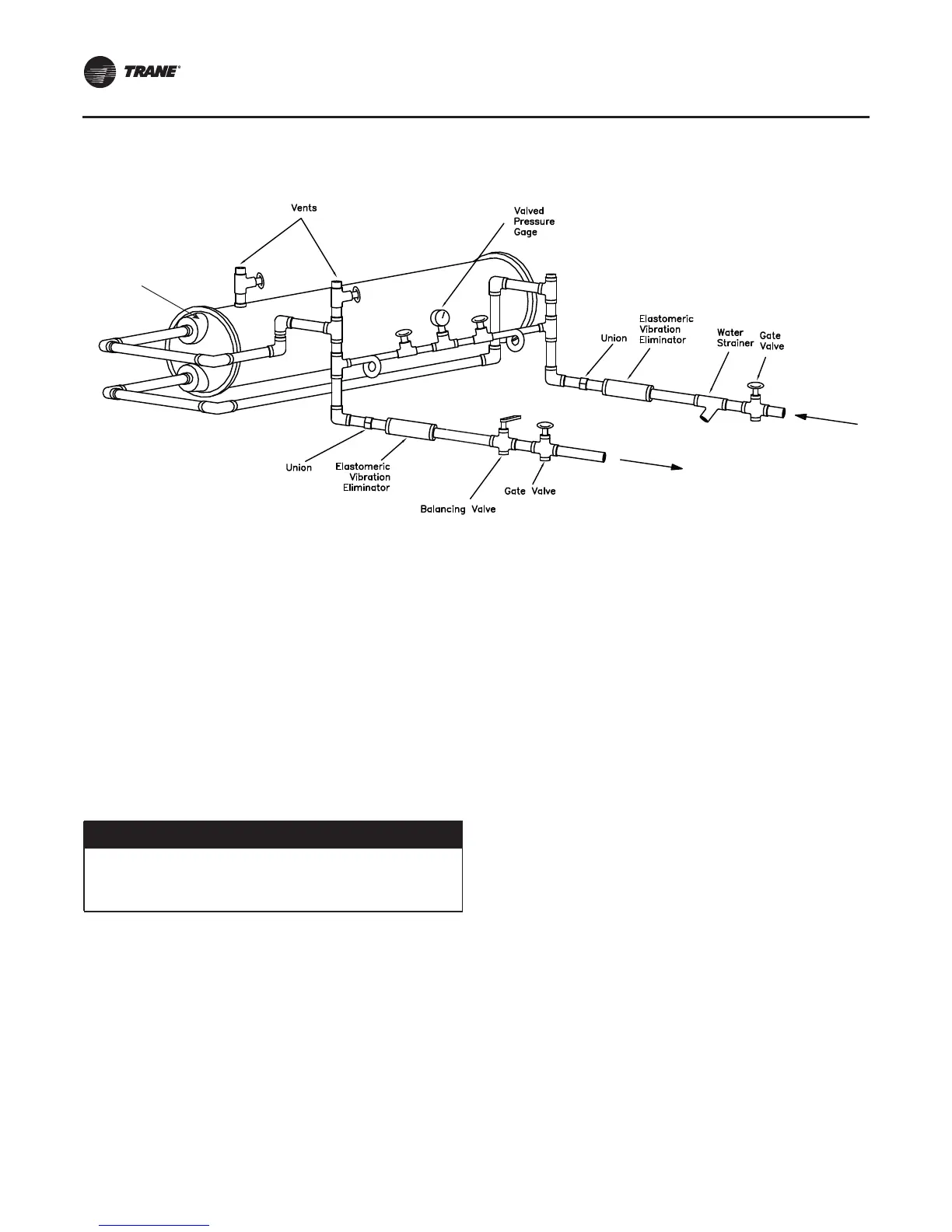

Install field-supplied pressure components as shown in

Figure 22, p. 52. Locate pressure gauges or taps in a

straight run of pipe; avoid placement near elbows, etc. Be

sure to install the gauges at the same elevation on each

shell if the shells have opposite-end water connections.

Note: Once the unit is installed at a site, one vertical or

one diagonal unit support can be permanently

removed if it creates an obstruction for water

piping.

To read manifolded pressure gauges, open one valve and

close the other (depending upon the reading desired).This

eliminates errors resulting from differently calibrated

gauges installed at unmatched elevations.

Water Pressure Relief Valves

Install a water pressure relief valve in the evaporator inlet

piping between the evaporator and the inlet shutoff valve,

as shown in Figure 22, p. 52. Water vessels with close-

coupled shutoff valves have a high potential for

hydrostatic pressure buildup on a water temperature

increase. Refer to applicable codes for relief valve

installation guidelines.

Freeze Protection

Depending on ambient temperature the unit may be

exposed to, there are multiple options for freeze

protection.They are listed in order of highest ambient

(least freeze protection) to lowest ambient (most freeze

protection).

Note: A secondary set of pump interlock is strongly

recommended, but not required.

1. Water pump AND heaters

a. Heaters are factory-installed on the evaporator and

water piping and will protect them from freezing in

ambient temperatures down to -20°F (-29°C).

b. Install heat tape on all water piping, pumps, and

other components that may be damaged if exposed

to freezing temperatures. Heat tape must be

designed for low ambient temperature

applications. Heat tape selection should be based

on the lowest expected ambient temperature.

Important: Heaters alone will provide low ambient

protection down to -20°F (-29°C), but will

NOT protect the evaporator from freezing as

a result of charge migration.Therefore, it is

required that water pump control be

used in conjunction with heaters.

c. CH530 controller can start the pump when freezing

conditions are detected. For this option the pump

must to be controlled by the RTAC unit and this

function must be validated.

d. Water circuit valves need to stay open at all times.

e. Verify heat tape is installed as noted in Step b.

Note: Water pump control and heater combination will

protect the evaporator down to any ambient

Figure 22. Suggested piping for typical RTAC evaporator

Flow Switch

(Factory Installed)

NOTICE:

Evaporator Damage!

To prevent shell damage, install pressure relief valves in

the evaporator water system.

Loading...

Loading...