Installation - Mechanical

48 RTAC-SVX01J-EN

Drainage

Provide a large capacity drain for vessel drain-down

during shutdown or repair. Evaporator is provided with

drain connection. All local and national codes apply. Vent

on top of evaporator waterbox is provided to prevent

vacuum by allowing air into evaporator for complete

drainage.

Evaporator Water Piping

Thoroughly flush all water piping to the unit before making

the final piping connections to the unit.

Evaporator Piping

Components and layout will vary slightly, depending on

the location of connections and the water source.

Provide shutoff valves in lines to the gauges to isolate

them from the system when they are not in use. Use

rubber vibration eliminators to prevent vibration

transmission through the water lines. If desired, install

thermometers in the lines to monitor entering and leaving

water temperatures. Install a balancing valve in the leaving

water line to control water flow balance. Install shutoff

valves on both the entering and leaving water lines so that

the evaporator can be isolated for service.

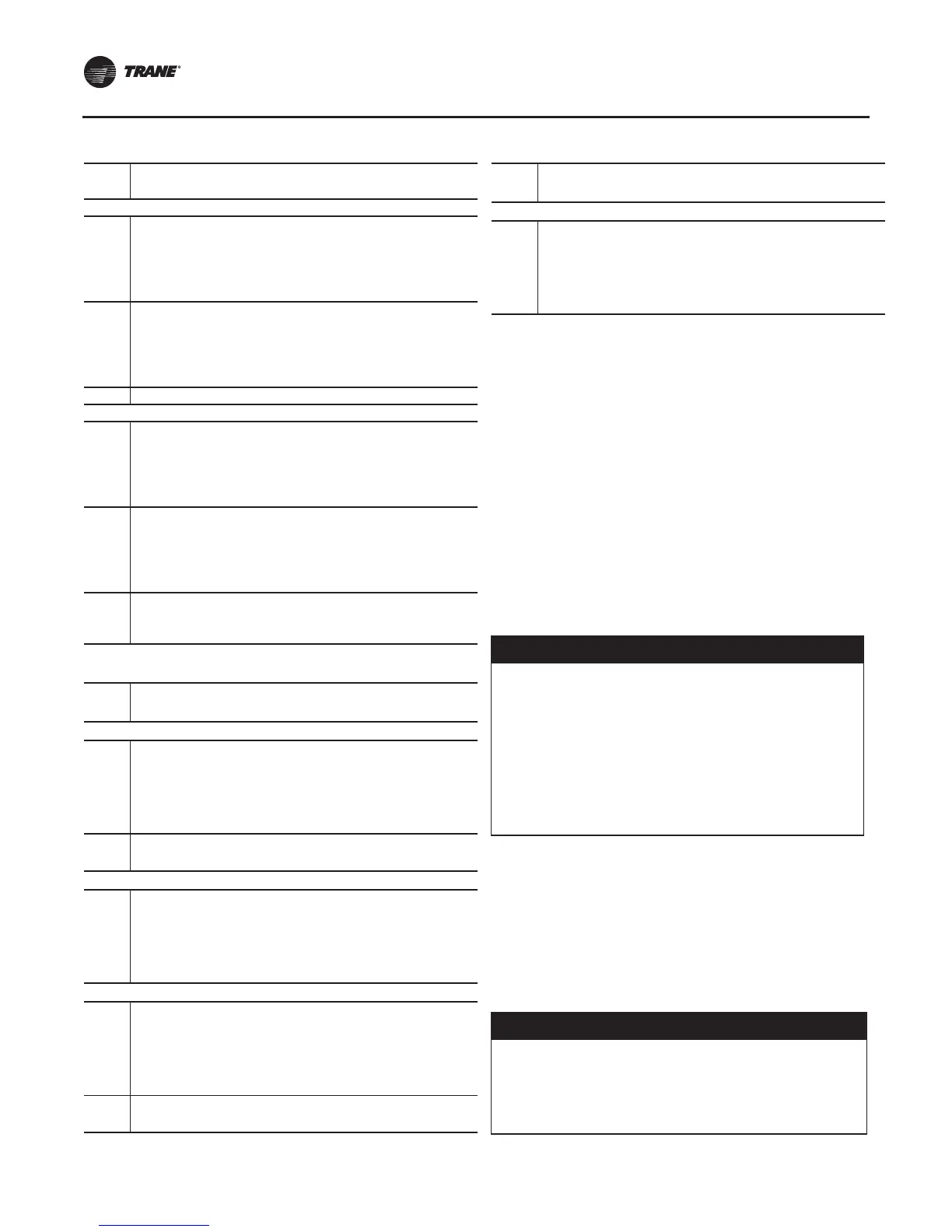

Copper Coils - Standard Efficiency

140 1658 1720 1675 1737 1695 1757 1715 1777 - -

155 1717 1728 1737 1742 1748 1750 1765 1775 - -

170 1717 1774 1737 1798 1765 1827 1793 1855 - -

185 2042 2121 2034 2112 2020 2038 2006 2090 - -

200 2056 2130 2055 2130 2055 2112 2054 2129 - -

250 2078 2332 2089 2356 2118 2385 2146 2413 2170 2437

275 2638 2933 2529 2805 2358 2653 2215 2501 2079 2384

300 2462 2718 2477 2732 2495 2784 2545 2782 2543 2798

350 3158 3137 3039 3018 2951 2894 2894 2873 2784 2779

375 3576 3579 3291 3255 3083 2948 2948 2912 2689 2690

400 3538 3498 3372 3350 3272 3207 3207 3184 3082 3077

Copper Coils - High Efficiency

120 1658 1720 1675 1737 1695 1757 1715 1777 - -

130 1658 1720 1675 1737 1695 1757 1715 1777 - -

140 1658 1720 1675 1737 1695 1757 1715 1777 - -

155 2025 2040 2012 2035 2009 2033 2007 2031 - -

170 2025 2100 3034 2098 2020 2038 2016 2090 - -

185 1839 1954 1842 1945 1846 1920 1859 1956 1857 1961

200 1891 1961 1890 1960 1887 1957 1885 1956 1883 1953

250 2505 2767 2418 2685 2321 2588 2224 2491 2170 2437

275 2488 2740 2529 2805 2581 2833 2639 2828 2720 2972

300 2825 3097 2766 3037 2690 2962 2605 2876 2526 2798

350 3000 2934 3184 3118 3281 3214 3429 3362 3628 3562

375 3576 3579 3442 3445 3309 3176 3176 3179 3043 3046

400 3445 3396 3516 3467 3587 3538 3658 3609 3730 3681

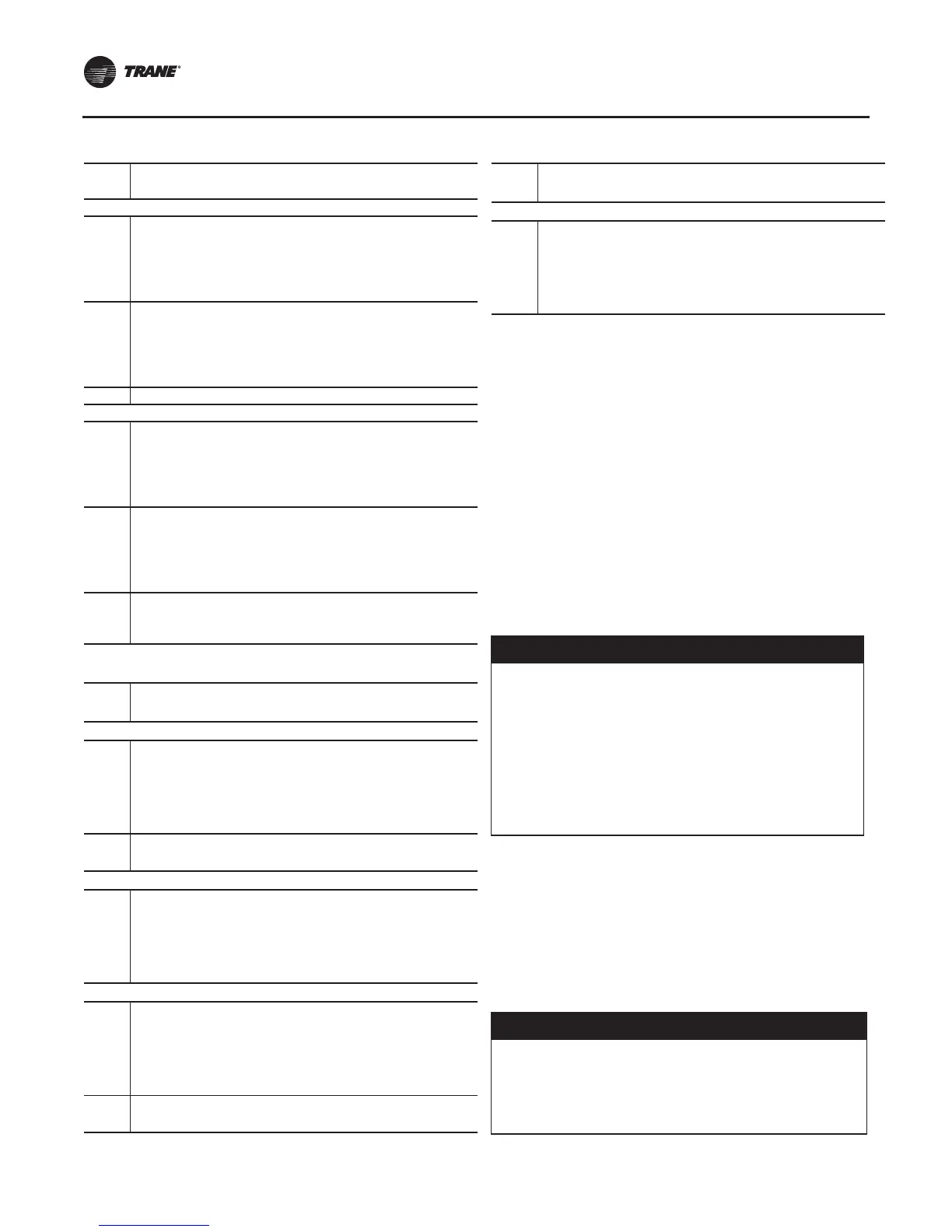

Table 26. Point weights (lbs) - remote units - 60 Hz

Size

(tons)

Isolator Location

12345678910

Aluminum Coils - Standard Efficiency

140 1150 1183 1095 1128 1032 1065 969 1002 - -

155 1150 1183 1095 1128 1032 1065 969 1002 - -

170 1150 1183 1095 1128 1032 1065 969 1002 - -

185 1381 1384 1325 1331 1241 1246 1156 1162 - -

200 1397 1437 1351 1391 1279 1318 1206 1246 - -

225 1251 1307 1222 1279 1172 1229 1126 1190 1081 1140

250 1274 1312 1246 1283 1196 1233 1149 1190 1103 1140

Aluminum Coils - High Efficiency

140 1150 1183 1095 1128 1032 1065 969 1002 - -

155 1321 1361 1270 1301 1190 1230 1109 1149 - -

170 1321 1361 1270 1314 1190 1230 1109 1149 - -

185 1175 1267 1151 1242 1107 1199 1067 1159 1027 1118

200 1251 1295 1222 1259 1172 1207 1122 1159 1081 1118

Copper Coils - Standard Efficiency

140 1406 1454 1388 1435 1366 1414 1345 1392 - -

155 1406 1454 1388 1435 1366 1414 1345 1392 - -

170 1406 1454 1388 1435 1366 1414 1345 1392 - -

185 1749 1772 1718 1744 1675 1700 1631 1656 - -

200 1768 1825 1745 1805 1713 1772 1680 1740 - -

225 1622 1697 1608 1686 1587 1665 1568 1645 1549 1625

250 1645 1702 1633 1690 1611 1668 1591 1648 1571 1628

Table 25. Point weights (lbs) - packaged units - 50 Hz

Size

(tons)

Isolator Location

12345678910

Copper Coils - High Efficiency

140 1406 1454 1388 1435 1366 1414 1345 1392 - -

155 1689 1749 1664 1714 1624 1673 1583 1644 - -

170 1689 1749 1664 1727 1624 1695 1583 1644 - -

185 1546 1657 1537 1649 1523 1634 1509 1621 1495 1599

200 1622 1686 1608 1666 1587 1642 1568 1621 1549 1607

NOTICE:

Evaporator Damage!

The chilled water connections to the evaporator are to

be “victaulic” type connections. Do not attempt to

weld these connections, as the heat generated from

welding can cause microscopic and macroscopic

fractures on the cast iron waterboxes that can lead to

premature failure of the waterbox. To prevent damage

to chilled water components, do not allow evaporator

pressure (maximum working pressure) to exceed 150

psig (10.5 bar).

NOTICE:

Evaporator Damage!

To prevent evaporator damage, pipe strainers must be

installed in the water supplies to protect components

from water born debris. Trane is not responsible for

equipment-only-damage caused by water born debris.

Table 26. Point weights (lbs) - remote units - 60 Hz

Size

(tons)

Isolator Location

12345678910

Loading...

Loading...