Chapter 9

Spindle Lubrication (for Series 3 Vision Tables only)

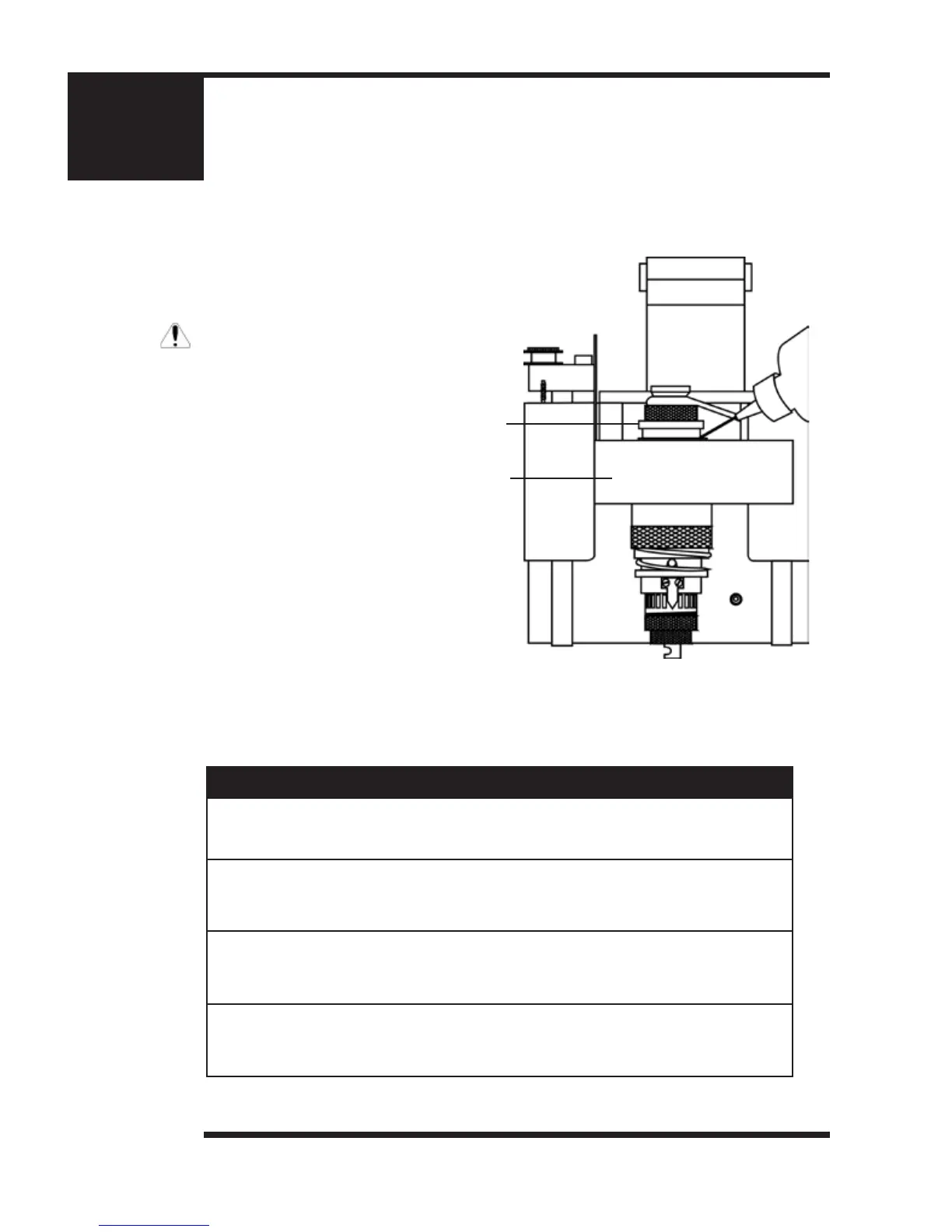

The spindle assembly in the Series 3 Vision Tables requires a

monthly lubrication of the housing (as shown in Fig.9.5). Simply

push the spindle up until there is a 1/3” gap between the

spindle block and the “lip” of the housing. Lubricate with

2 to 3 drops of 3 in 1 oil.

DO NOT OVER LUBRICATE!

Never lubricate the spindle bearings!

This wil cause the spindle to stick.

MAINTENANCE SCHEDULE

The following is a suggested maintenance schedule. Remember that in conditions of

prolonged use, unusual environments, or unusual applications, maintenance items

may need to be performed more frequently than suggested in this schedule.

Spindle Housing “Lip”

Spindle Block

Frequency Maintenance Items

As needed 1. Vacuum and/or brush

2. Clean vacuum canister lters

Every Day 1. Remove chips form the spindle if

you do not have a vacuum chip

removal assembly.

Every Month 1. Lubricate the Z-Axis lead screw

2. Lubricate the Spindle Housing

3. Lubricate steel X, Y lead screws

Every Six Months 1. Check the motor brushes and

replace if necessary.

2. Lubricate the Z-Axis linear bearing

(Figure 9.5)

Loading...

Loading...