30

Maintenance: Engine, general

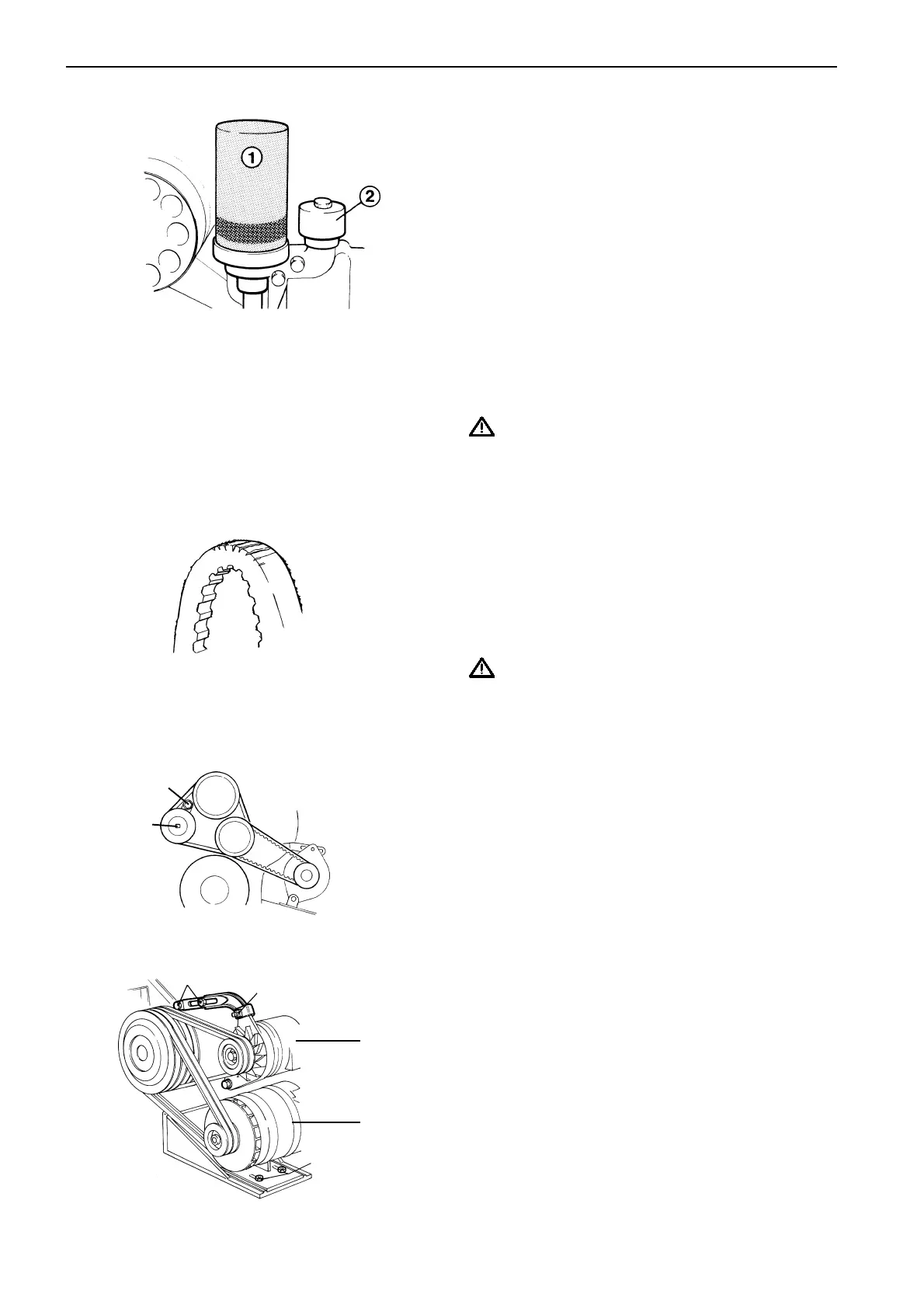

Crankcase ventilation. Change filter

Change the filter (1) earlier than recommended if oil is

forced out of the relief valve (2).

1. Dismantle the filter (1) by screwing it anti-clock-

wise.

2. Check the rubber gasket in the bracket and

change if necessary. Screw on the new filter by

hand.

Drive belts. Check/Adjust/Change

WARNING! Stop the engine before commenc-

ing maintenance work.

General

Check belt tension and condition regularly. If the belt

is too taut it can damage bearings and if it is too loose

it may slip. Check and adjust after operation when the

belt is warm.

The belt is correctly tensioned when it can be de-

pressed approximately 10 mm between the pulleys.

Clean the belt grooves before fitting a new belt.

IMPORTANT! Always change a belt that ap-

pears worn or is cracked (belts working in pairs

must be replaced together).

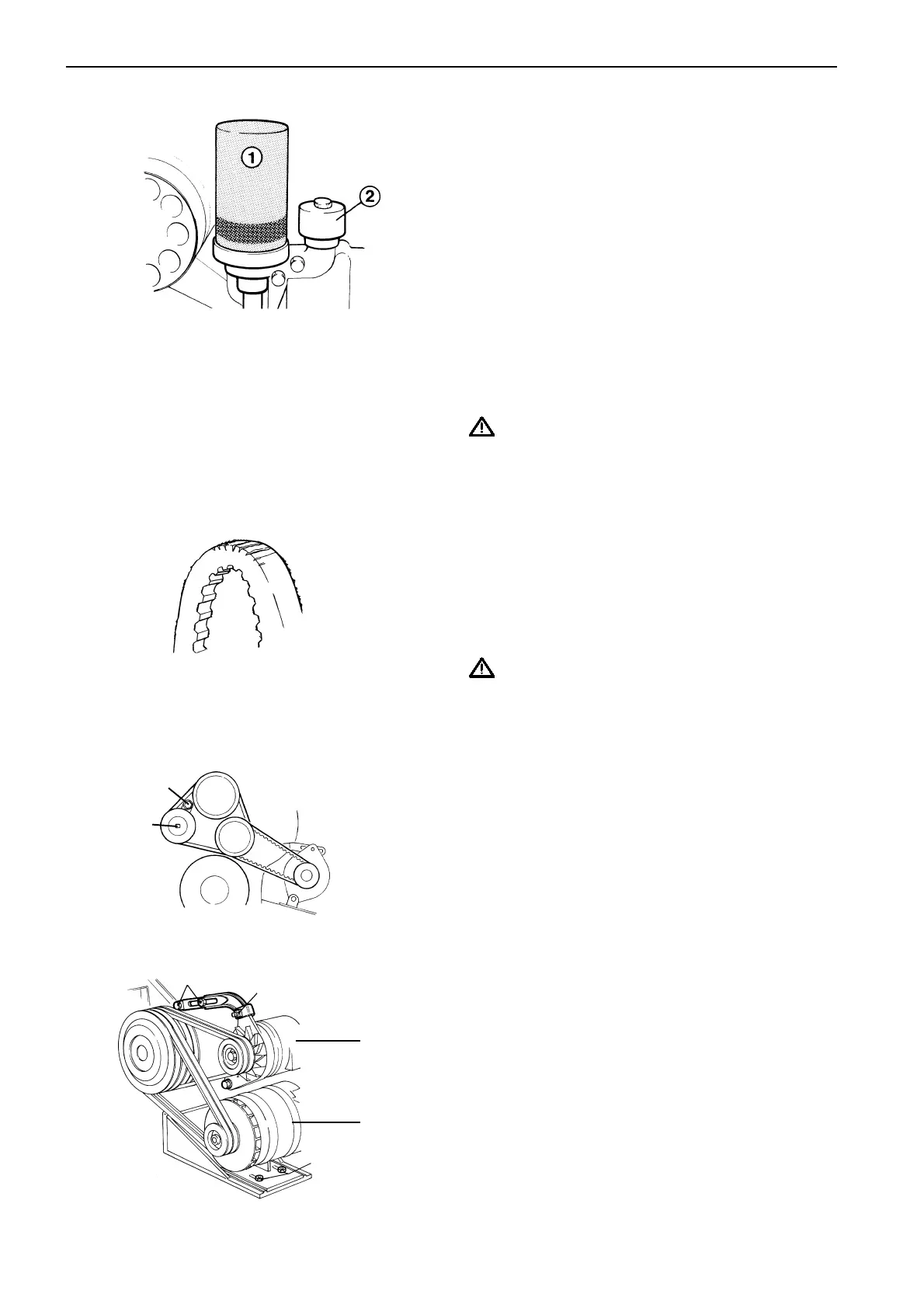

Adjust/Change

Circulation pump belts

1. Undo the belt (A)

2. Change belts if necessary

3. Place the drive pin of a ratchet handle into the

square hole (B) and tighten the belts.

4. Tighten the bolt (A)

Generator belts

The standard generator (1) can be placed low or high.

The generator (2) is an accessory.

1. Undo the bolt/bolts (C)

2. Change belts if necessary

3. Tension the belts

4. Tighten the bolt/bolts (C)

Other belts

Check also belts for other equipment. Adjust and

change as necessary.

A

B

C

C

C

2

1

Loading...

Loading...