52

Repair instructions

6

Remove the press tool and mandrel.

(6x series): Install the cylinder head screws and

torque them. Please refer to “Cylinder head, installa-

tion” on pages 46 and 47.

7

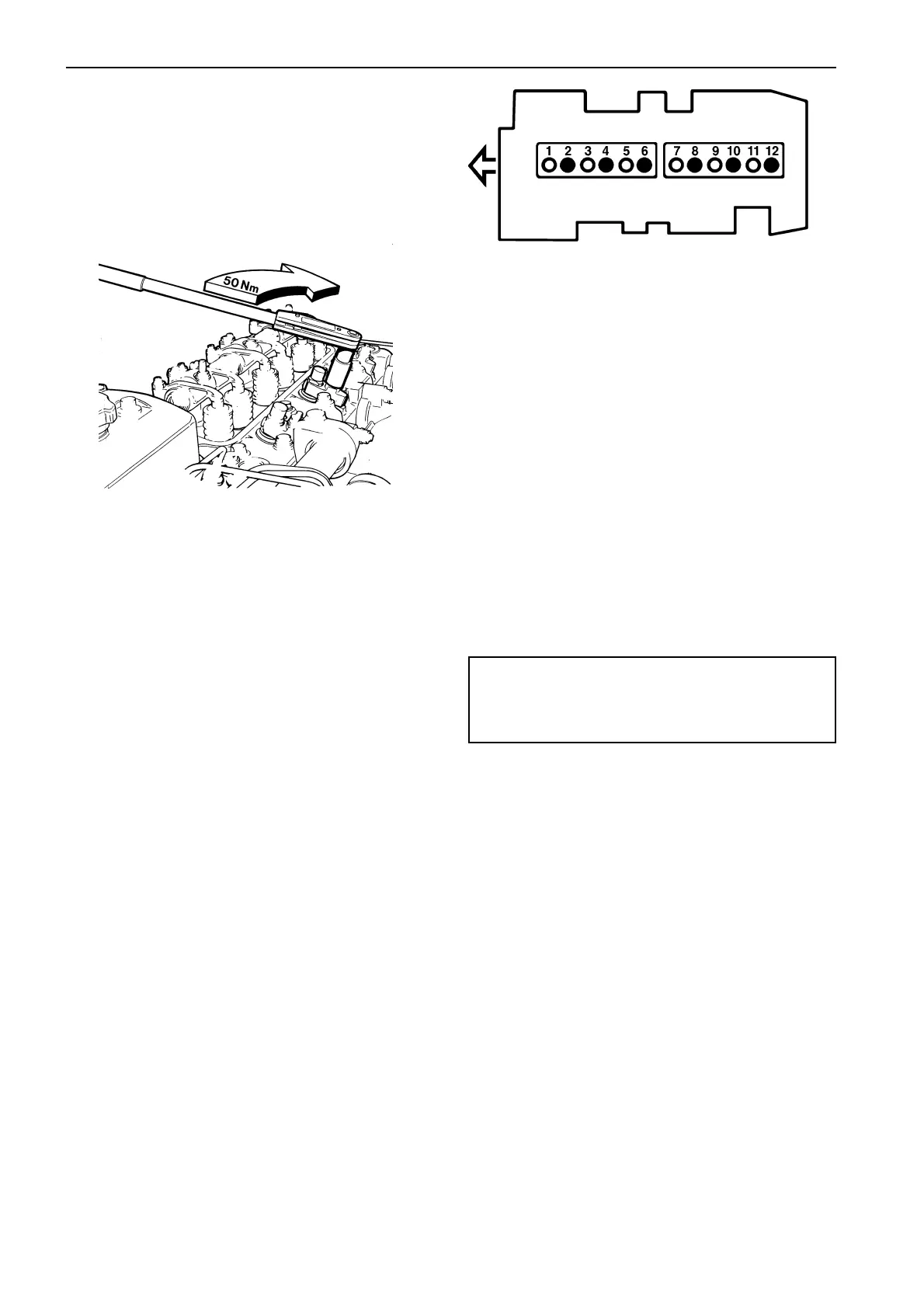

Install the injectors with dust covers and yokes.

Tightening torque is 50 Nm (5.0 kpm/37 lbf.ft). Install

the valve covers and oil leakage pipes.

8

Install the delivery pipes. Check that they have not

been skewed and tighten the nuts.

Tightening torque is 15–25 Nm (1.5–2.5 kpm/11–18

lbf.ft).

9

Fill up with coolant. Do a leakage check.

Valves, adjustment

NOTE! The clearance must never be checked when

the engine is running, it must be done with the engine

stationary, cold or at operating temperature.

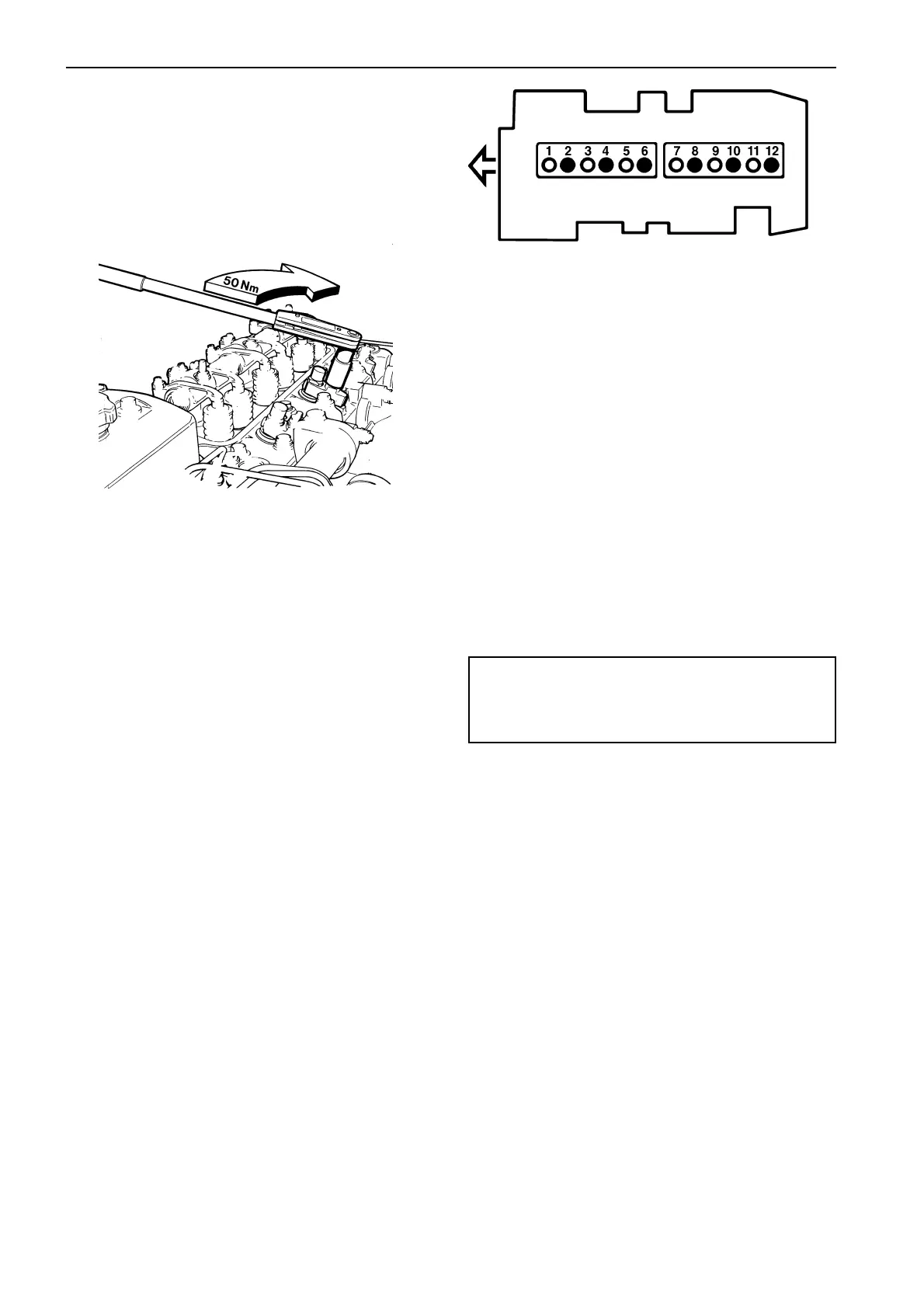

Inlet ❍

Exhaust ●

Valve location and cylinder numbering

Valve clearance,

Inlet Exhaust

TAMD61, TAMD62,............. 0.40 mm 0.55 mm

TAMD71 (0.0157”) (0.0217”)

TAMD63, TAMD72,............. 0.50 mm 0.65 mm

TAMD73, TAMD74 (0.0197”) (0.0256”)

1

Remove the valve covers. When the valve clearance

is checked, the engine must only be cranked in its

normal direction of rotation. Cranking is done by turn-

ing the polygon hub on the crankshaft nose with a 21

mm ratchet spanner.

Firing sequence 1 5 3 6 2 4

Cylinder whose

rockers “tip” 6 2 4 1 5 3

2

Crank the engine in its normal direction of rotation un-

til the No. 1 piston is at TDC after the compression

stroke. This will cause the valves for cylinder No. 6 to

“tip”.

3

Crank the engine a third of a stroke in the correct di-

rection of rotation, and check the valve clearance for

piston No. 5. At the same time, the valves for cylinder

No. 2 will “tip”. Check the valve clearance for the

other cylinders in the firing sequence.

4

Clean the valve covers, replace damaged gaskets.

Tightening torque for nuts for the valve cover is

24 Nm (2.4 kpm/18 lbf.ft).

Test the engine and check that no oil leakage occurs.

Loading...

Loading...