81

Repair instructions

Gear ring, replacement

(Flywheel removed)

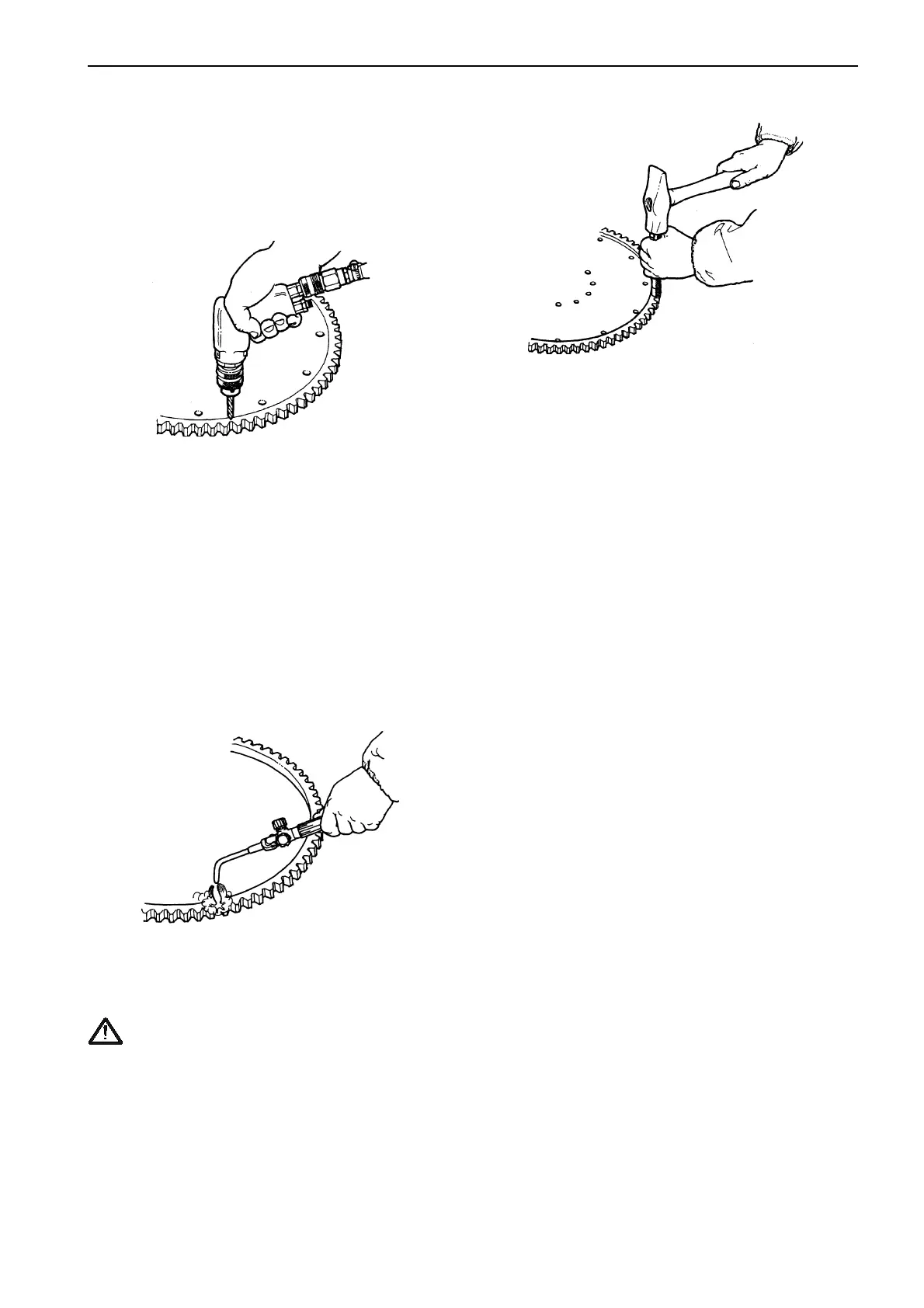

1

Drill 1–2 holes in the gap between two teeth on the

gear ring.

Split the gear ring across the drilled holes, using a

hammer and cold chisel.

2

Brush the mating surface of the flywheel with a wire

brush.

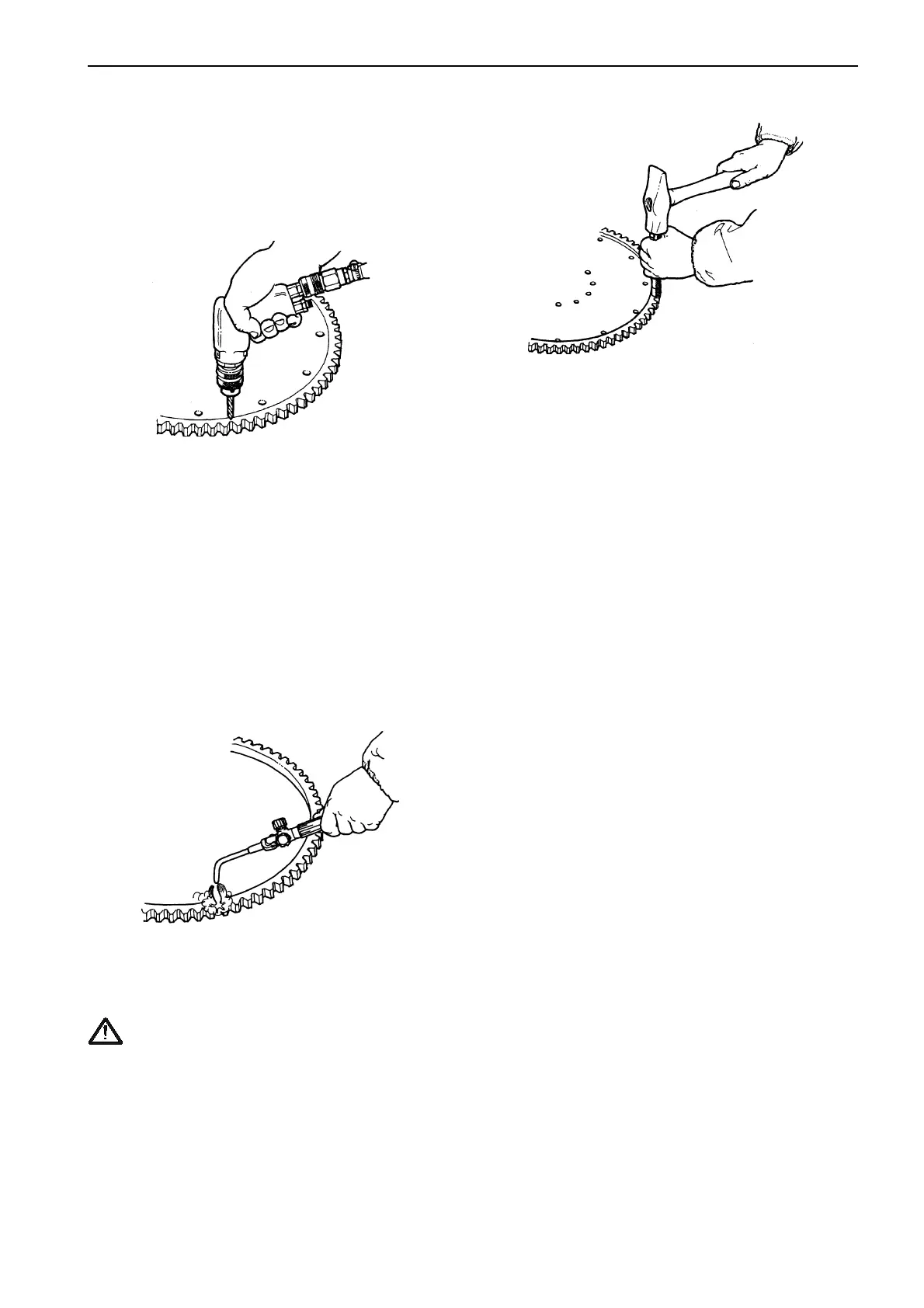

3

Heat up the new gear ring in an oven, or with a weld-

ing torch, to max 180–200°C.

WARNING. If you use a welding torch, take

great care to ensure that the gear ring is evenly

heated, and not spot heated, which would

cause annealing. To check the heating

process, polish the gear ring bright at several

places before heating it. Stop heating when

these surfaces become blued.

4

Put the heated gear ring on the flywheel and tap it

into place with a soft punch and hammer.

Allow the gear ring to air cool.

5

Clean the mating surfaces on the flywheel and crank-

shaft. Check the location dowel in the crankshaft

flange and the rear crankshaft seal. Replace

if necessary.

Install the flywheel. Tightening torque is 190 ±10 Nm

(19 ±1.0 kpm).

Loading...

Loading...