59

Repair instructions

Cylinder liner seat, renovation

Special tools: 9989876, 9992479, 9996847 (2 No.),

9999508 (7x series), 9999514 (7x series), 9999538

(6x series), 9999553 (6x series)

A damaged cylinder liner seat is repaired by milling

the lining shelf. Check the mating face of the upper

lining seat with marking dye if there is any doubt

about the extent of the damage. The material which is

removed during milling should be compensated

by spacers which are available in thicknesses of

1.12 mm (only 7x series), 0.20 mm, 0.30 mm and

0.50 mm.

NOTE! If spacers are to be used, the lining seats will

have to be machined slightly, even if the seats are un-

damaged, this is because the fillet radius has to be re-

moved to allow the spacers to seat correctly.

Clean the upper and lower lining seats and estimate

the extent of the damage. The upper seat must be ab-

solutely clean from carbon deposits. Clean

the mating surfaces with a brush and cleaning fluid.

Scraping tools must not be used in any circum-

stances. Blow dry with compressed air.

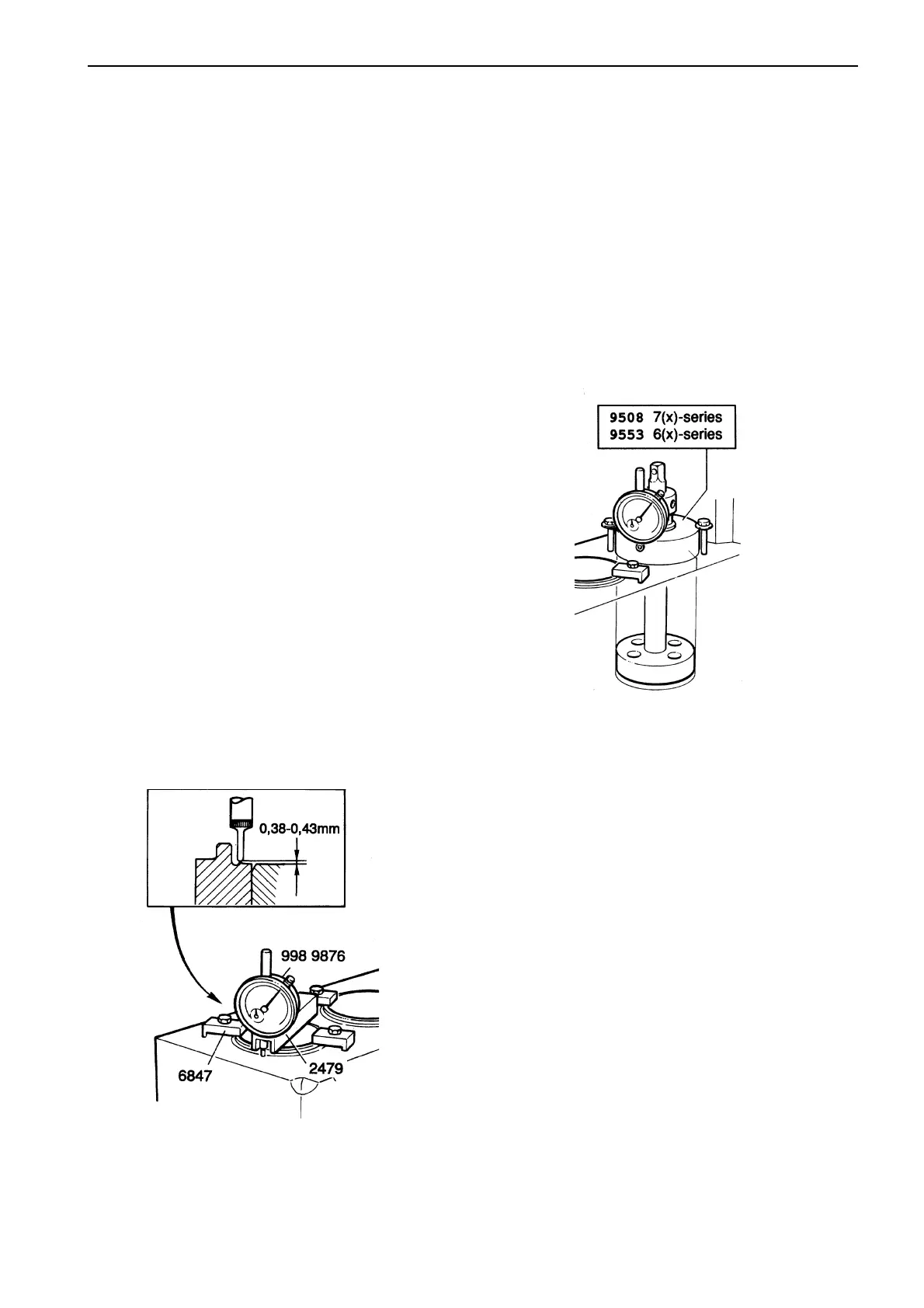

Calculate the thickness of spacers needed, on the ba-

sis of the measurements you have made. Try to use

the thinnest possible spacer, preferably only one

should be used. The correct height above the block

plane should be 0.38–0.43 mm.

2

Remove the liner and roughen up the surface of the

lining seat with an emery cloth.

Install the cylinder liner without sealing rings, and

press it down with holder 9996847 (2 No.).

Measure the height of the liner above the plane of the

block at four different locations, using a dial gauge

and measurement jig 9992479.

1

3

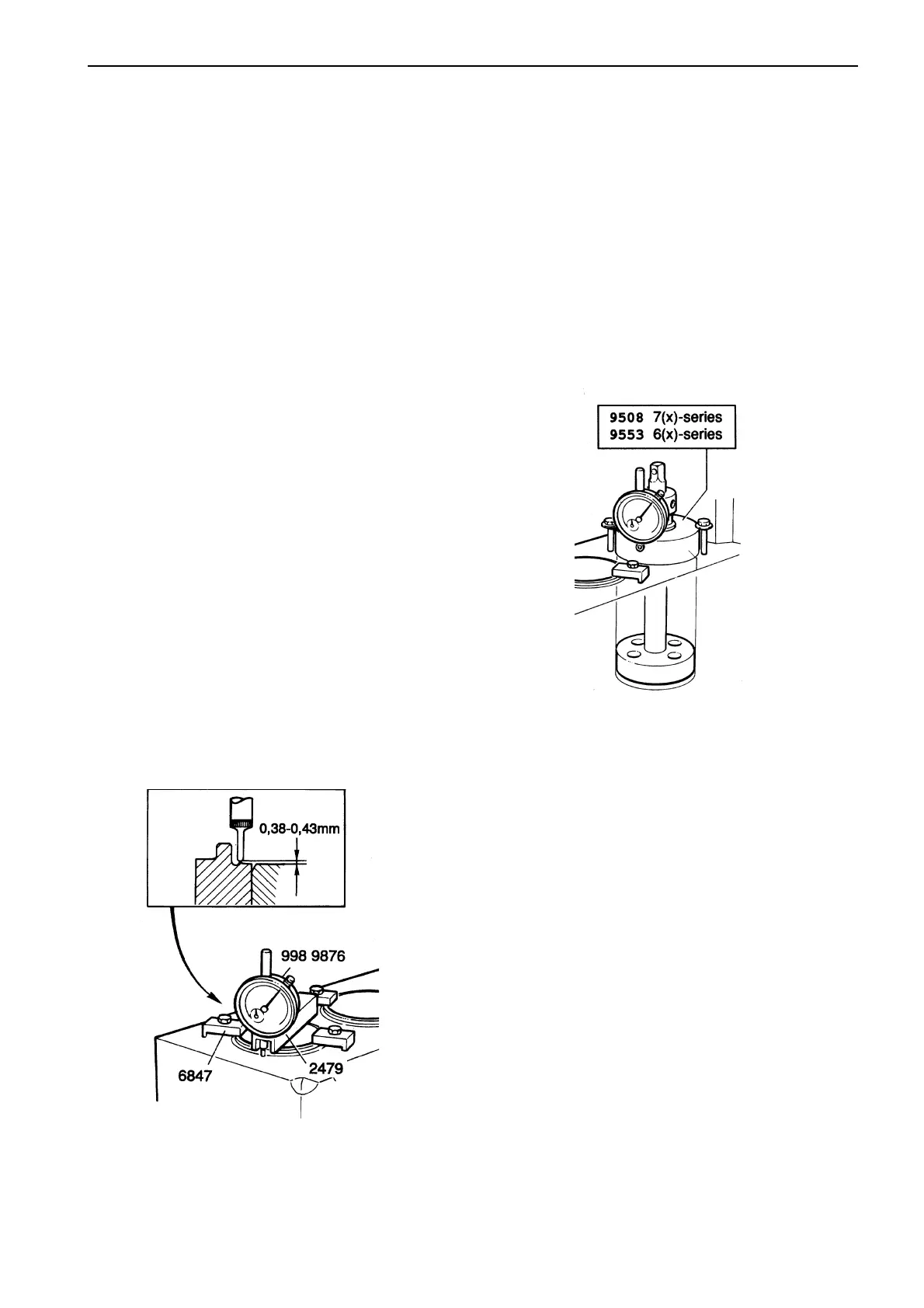

Screw milling tool no. 9999553 (6x series) or 9999508

(7x series) to the cylinder block.

Make sure that the feed sleeve does not press on the

cutter.

4

Screw down the feed sleeve so that it presses the

cutter lightly. Use a T handle (not a ratchet handle) to

turn the cutter.

The cutter should be turned with an even movement,

at the same

time as the feed sleeve is turned. When

the correct height has been reached, stop feeding and

turn the cutter a few turns.

Remove the milling tool and clean the liner seat care-

fully.

Check the mating surface of the lining seat very care-

fully, and the height of the step edge at regular inter-

vals.

NOTE! Mark the position of the liner against the cylin-

der block with a felt tip marker pen, so that it comes

back to the same position again.

Loading...

Loading...