82

Repair instructions

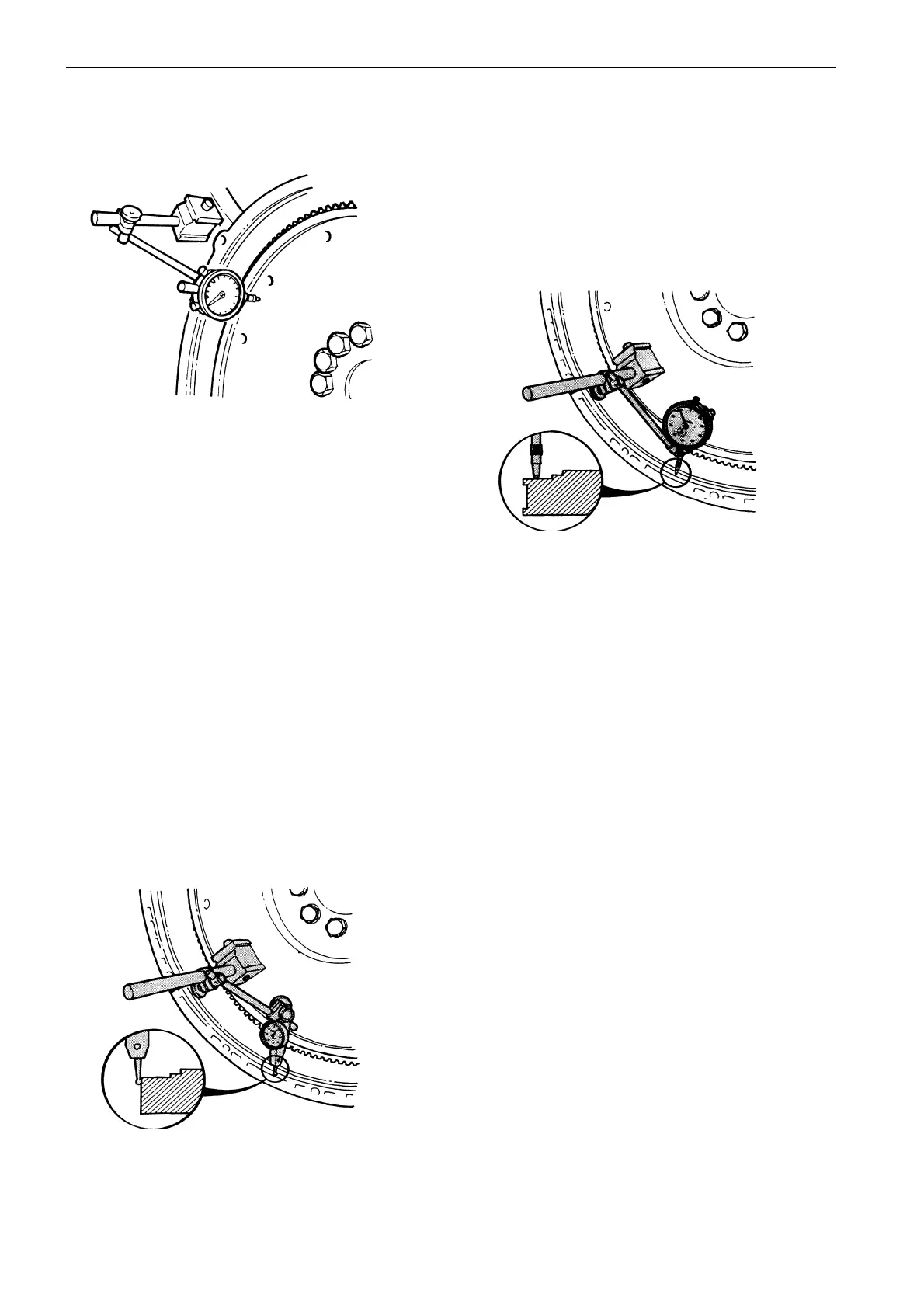

Flywheel, indication

Special tools: 9999696, 9989876

1

Place a dial indicator with its tip on the flywheel.

2

Zero the dial gauge. Turn the flywheel round and

read off the greatest value.

The measured value must not exceed 0.15 mm, at a

measurement radius of 150 mm.

If the flywheel is more skewed, remove the flywheel

and check whether there is dirt or unevenness be-

tween the flywheel and the crankshaft flange.

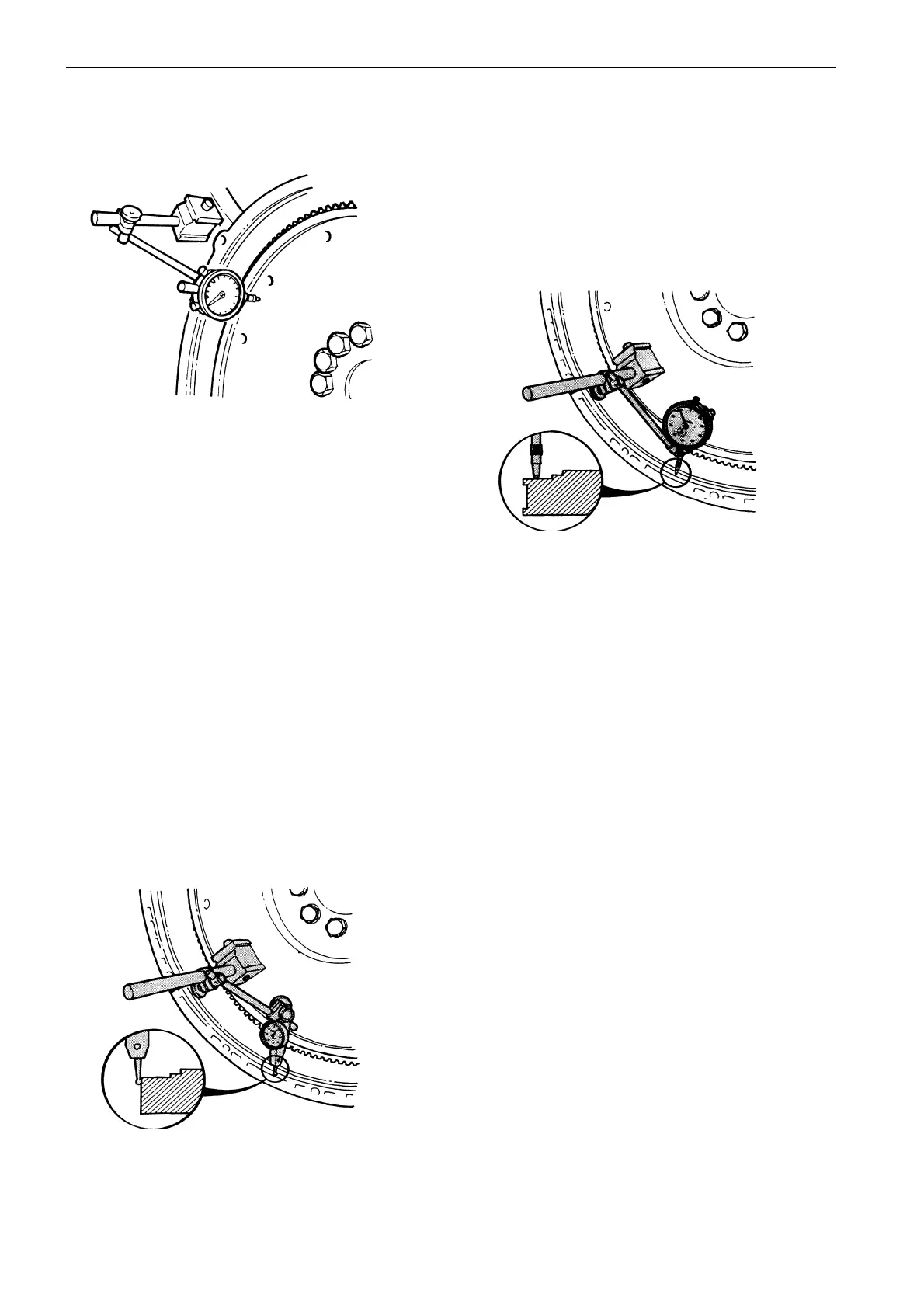

Put the magnetic base of the dial gauge on the fly-

wheel, and put the tip of the dial gauge on the outer

edge of the flywheel housing (see illustration).

Read off the value, and move the dial gauge with

base round to the opposite side of the flywheel.

The value of these measurements must not exceed

0.15 mm.

Put the magnetic base of the dial gauge on the fly-

wheel, and put the tip of the dial gauge on the inner

edge of the flywheel housing (see illustration). Pull

the flywheel round and read off the indication.

Centring of the inner edge of the flywheel housing,

relative to the flywheel, must be within 0.25 mm.

If any of the values should exceed 0.25 mm, the lo-

cation of the flywheel housing against the engine

block should be checked.

2

1

Flywheel housing, indication

Special tools: 9999696, 9989876

Loading...

Loading...