70

It has been found that the damage only gets worse in

very rare cases.

Check the camshaft bearing surface and cam profiles

for wear. The cams can be worn obliquely in the

lengthwise direction, for example.

This can be adjusted in milder cases by stoning the

cam profile. Replace the camshaft if there is any

other damage or wear.

When the camshaft is replaced, all the valve

lifters must be replaced at the same time.

Camshaft measurement

Camshaft measurement

Measure the camshaft bearing surface with a mi-

crometer. The maximum wear and ovality is

0.07 mm.

The straightness of the shaft is checked by indication.

The maximum run-out in relation to the end bearings

is 0.04 mm.

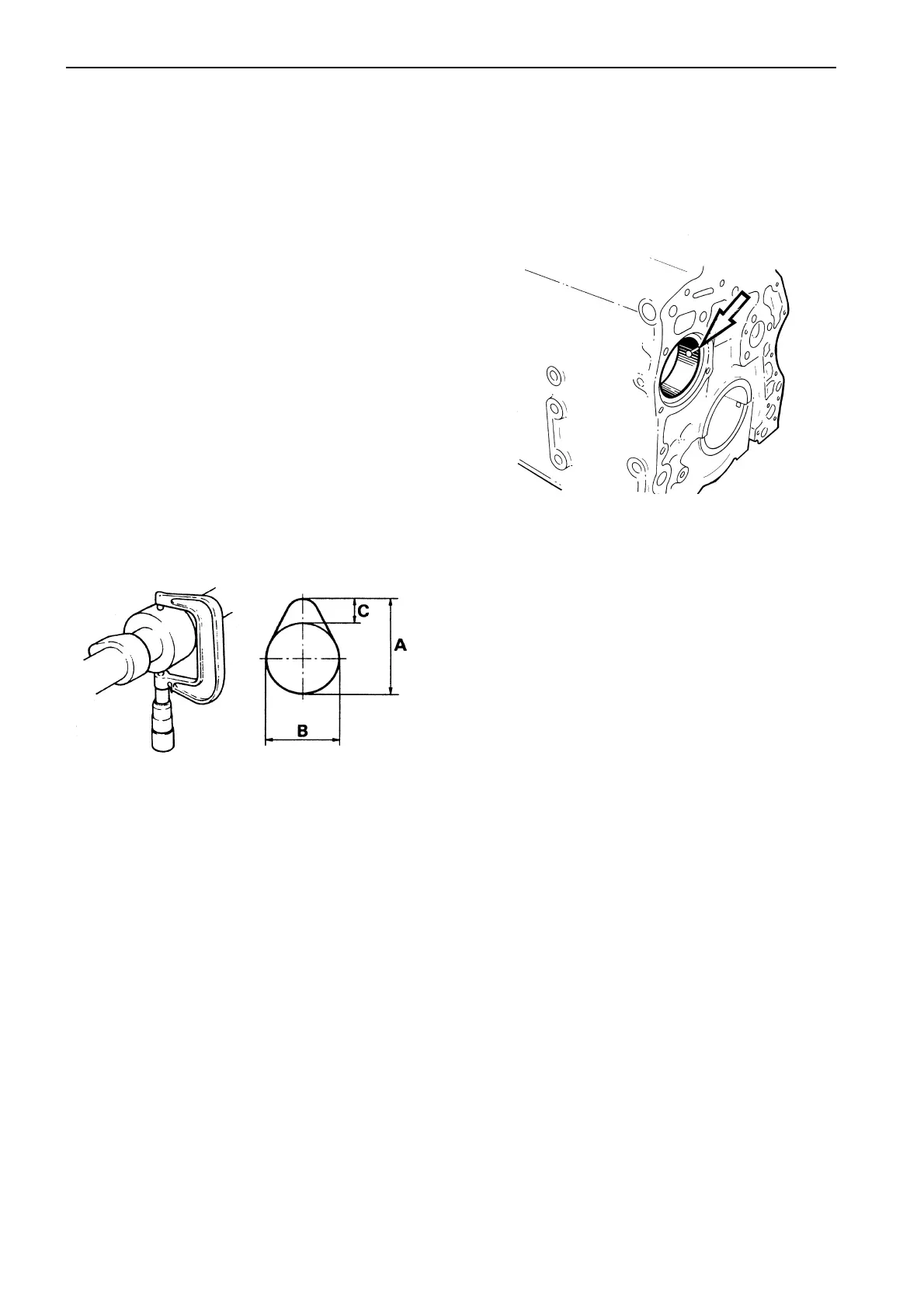

Measure the lift height (cam height) with a calliper

gauge, as in the illustration above.

Lift height C = A – B (The lift height can also be mea-

sured by the “Camshaft wear check” method on page

67.

Please refer to “Technical Data” for the measurements

of the camshaft and camshaft bearings. Also, please

refer to the table on page 68 for the lift height.

Camshaft bearing,

replacement

The bearings are pressed into their locations and must

be bored after pressing in. This means that the cam-

shaft can only be replaced in conjunction with a total

overhaul of the engine.

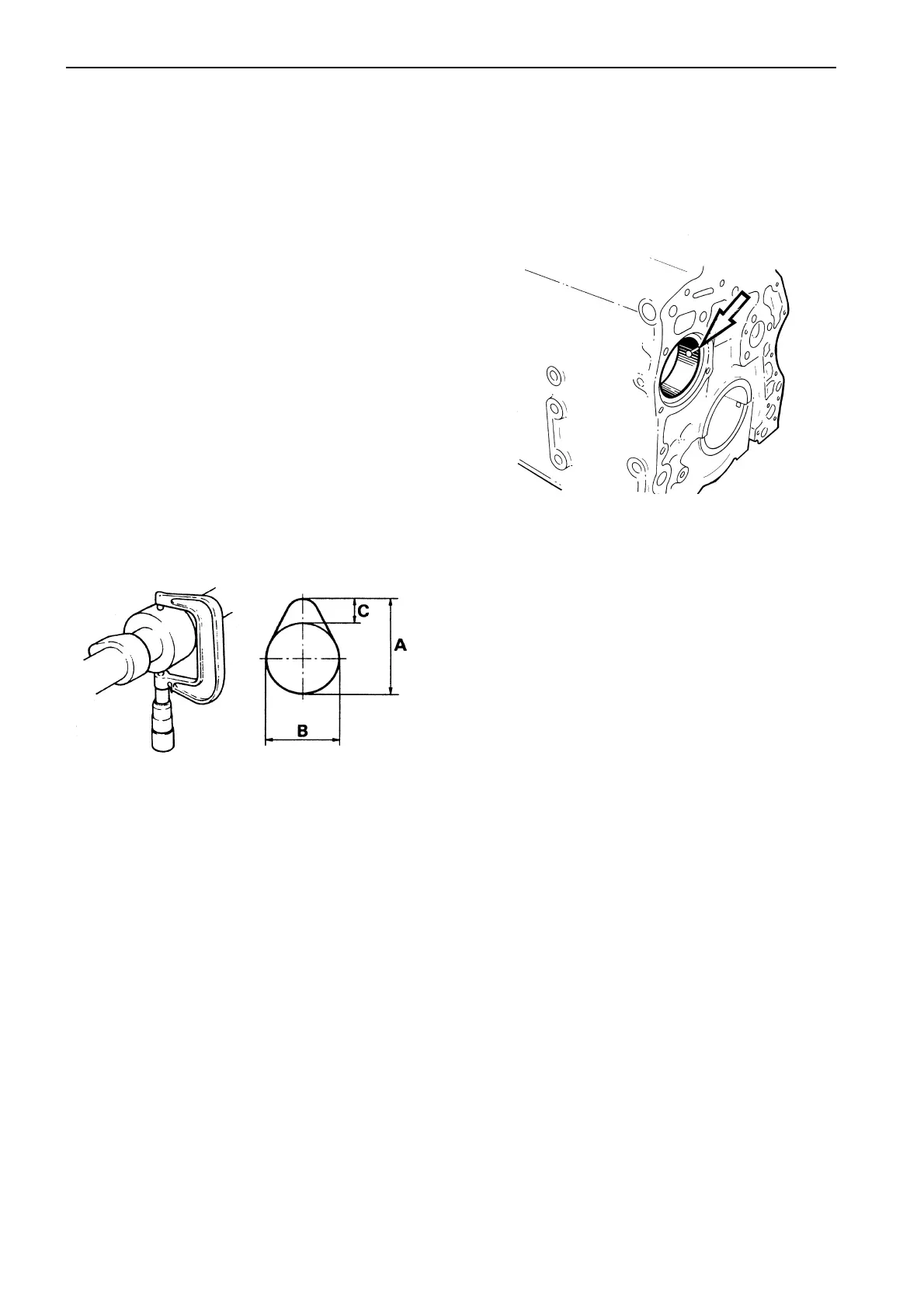

Oil holes in bearings

Check when you press the bearings in, that the oil

holes are centred on the corresponding oil duct in the

block.

The front camshaft bearing should be installed with

the groove aligned forwards.

Repair instructions

Loading...

Loading...