上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

- 72 - Specialized, Concentrated, Focused

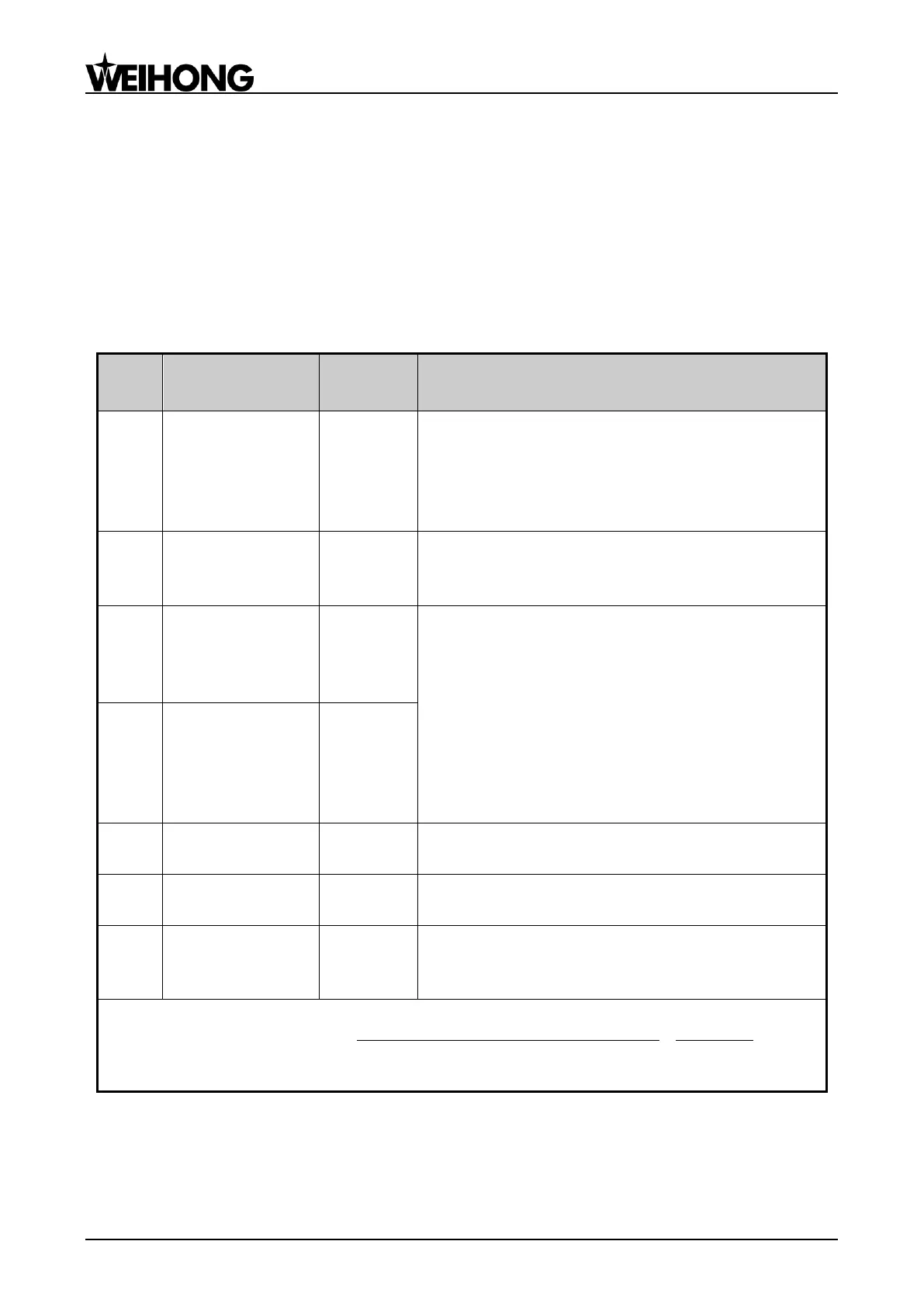

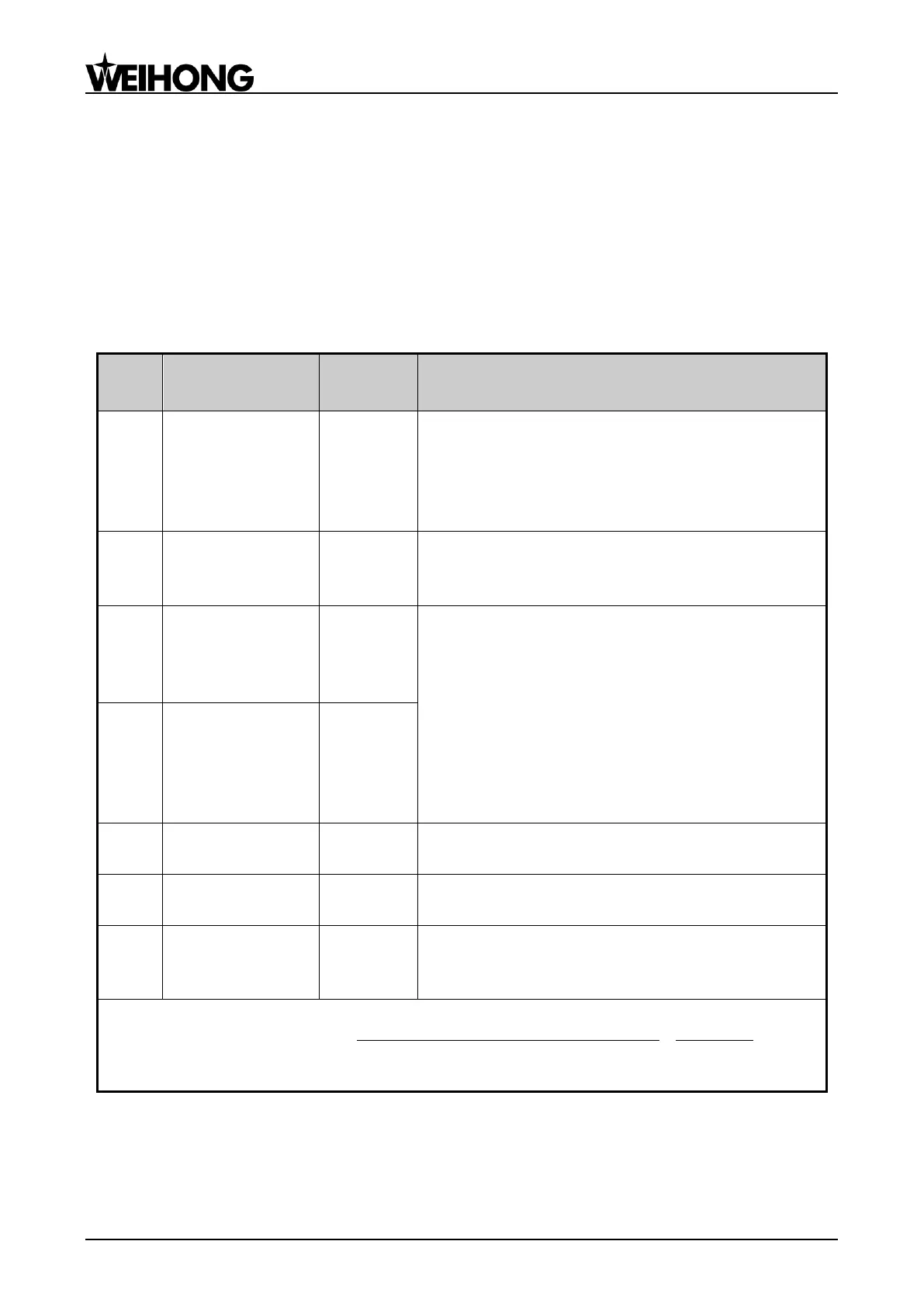

5.4 Driver Parameters

Driver parameters listed in the following chapters can only ensure normal working of a machine tool,

without ensuring machining results. To get a better machining result, you need to set those parameters

according to actual situations.

5.4.1 Lambda 3S/3L Series

5.4.1.1 Parameter Setting of WISE Servo Driver

Monitor if the number of sent and received pulses is

correct by setting this parameter. In Weihong control

system, the correct quantity of pulses sent by control

card is detected by pulse inspection in order to

determine whether there is electrical interference.

Command pulse

No. per motor

circle

When it is set to ―0‖, parameters Pr009 and Pr010 are

valid.

1

st

numerator of

command pulse

frequency division/

multiplication

Range: 0~2

30

Typical value: pitch 5 mm, encoder resolution 10000,

deceleration ratio 1:1, pulse equivalent 0.001 mm:

Pr009=10000

Pr010=pitch 5mm/ pulse equivalent 0.001mm=5000

Pr009/Pr010=10000/5000=2/1

Denominator of

command pulse

frequency

division/multiplicati

on

Unit: 0.1/s. Set it according to the actual situation.

Unit: 0.1Hz. Set it according to the actual situation.

1st velocity loop

integrated time

constant

Unit: 0.1ms. Set it according to the actual situation.

When the value of Pr008 is not ―0‖, it can be calculated in terms of the following formula:

Screw pitch 5mm

Command pulse No. per motor circle 5000

Pulse equivalent Mechanical deceleration ratio 0.001mm/ p

When screw pitch is 5mm and pulse equivalent 0.001, the value of Pr008 is ―5000‖.

Loading...

Loading...