上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

- 74 - Specialized, Concentrated, Focused

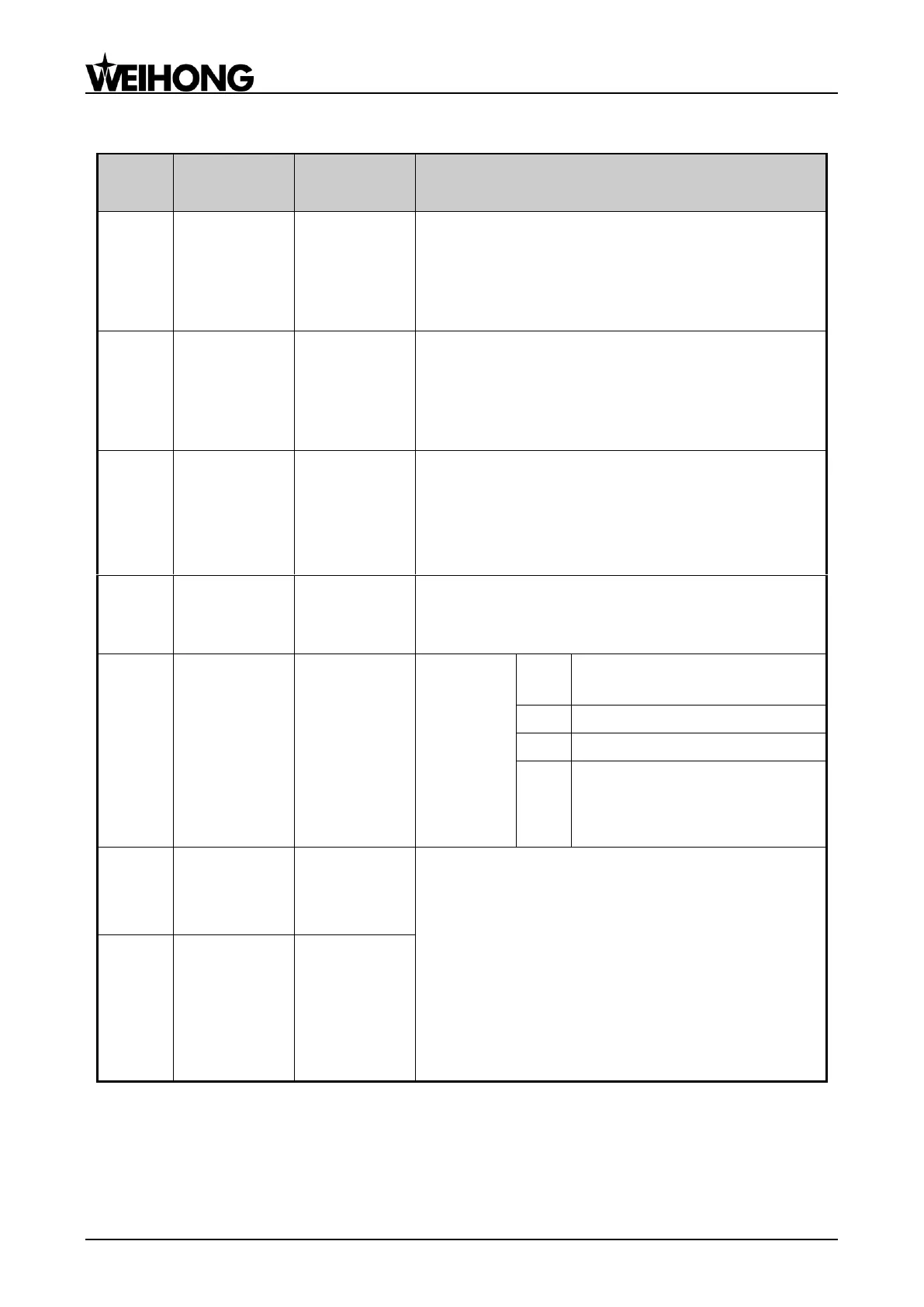

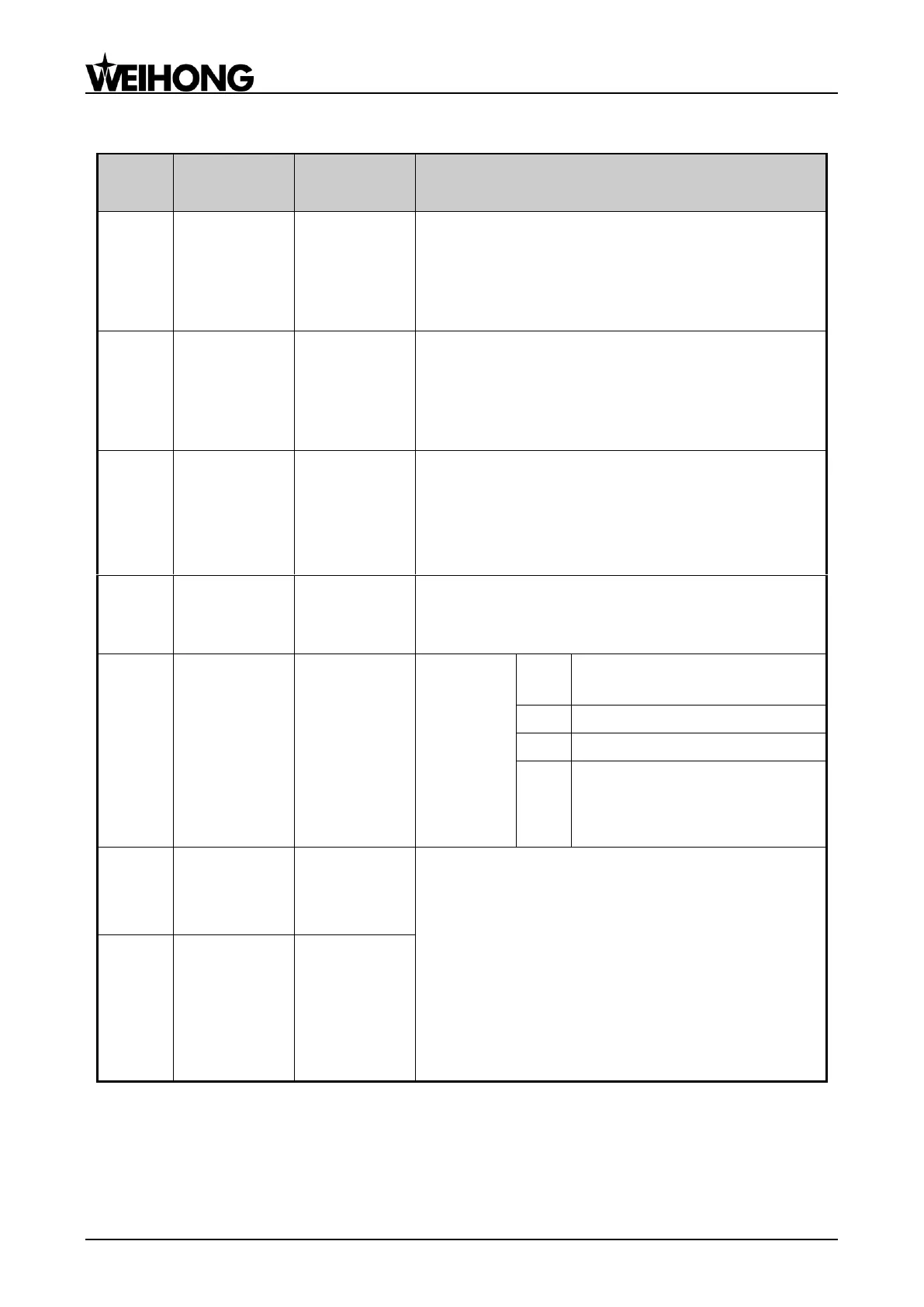

5.4.1.2 Parameter Setting of YASKAWA Σ–Ⅱ Servo Driver

LXXXX

(Hexadecimal

system)

Monitor if the number of sent and received pulses is

correct by setting this parameter. In Weihong control

system, the correct quantity of pulses sent by control

card is detected by pulse inspection in order to

determine whether there is electrical interference.

Direction

selection

Control mode

selection

Bit 0: Set 0, ―CCW‖ is forward rotation (viewed from the

load end of screw ball); Set 1, the rotation direction of

the motor is reversed.

Bit 1: Set 1, position control mode (calculate pulse

instruction all the time).

Selection

servo off or

alarm stop

mode

Bit 0: Set ‖0‖, stopping the motor by applying dynamic

brake(DB) which will be maintained after stop;

Set ‖1‖, stopping the motor by applying dynamic

brake(DB) and then the motor can rotate freely after

stop.

Select pulse

instruction

mode

Bit 0: Set 5, select the instruction input mode as ―pulse

+ direction‖, negative logic.

Bit 3: Set 0, input differential signal into filter.

Encoder

cycle-divided

ratio

(Pulses output

per motor

cycle by

encoder after

cycle-divided)

Encoder Pulse No. per Motor

Circle (pulse/ revolution)

Electronic

gear ratio

(numerator)

Pn202 = pulse No. of each encoder circle × 4 ×

mechanical deceleration ratio.

Pn203 = (screw pitch/ pulse equivalent).

Typical value: pitch 5mm, encoder 17-bit, deceleration

ratio 1:1, pulse equivalent 0.001mm, Pn202=16384;

Pn203=625.

Pitch 5mm, encoder 17-bit, deceleration ratio 1:1,

pulse equivalent 0.0005mm, Pn202=8192; Pn203=

625.

Electronic

gear ratio

(denominator)

Loading...

Loading...