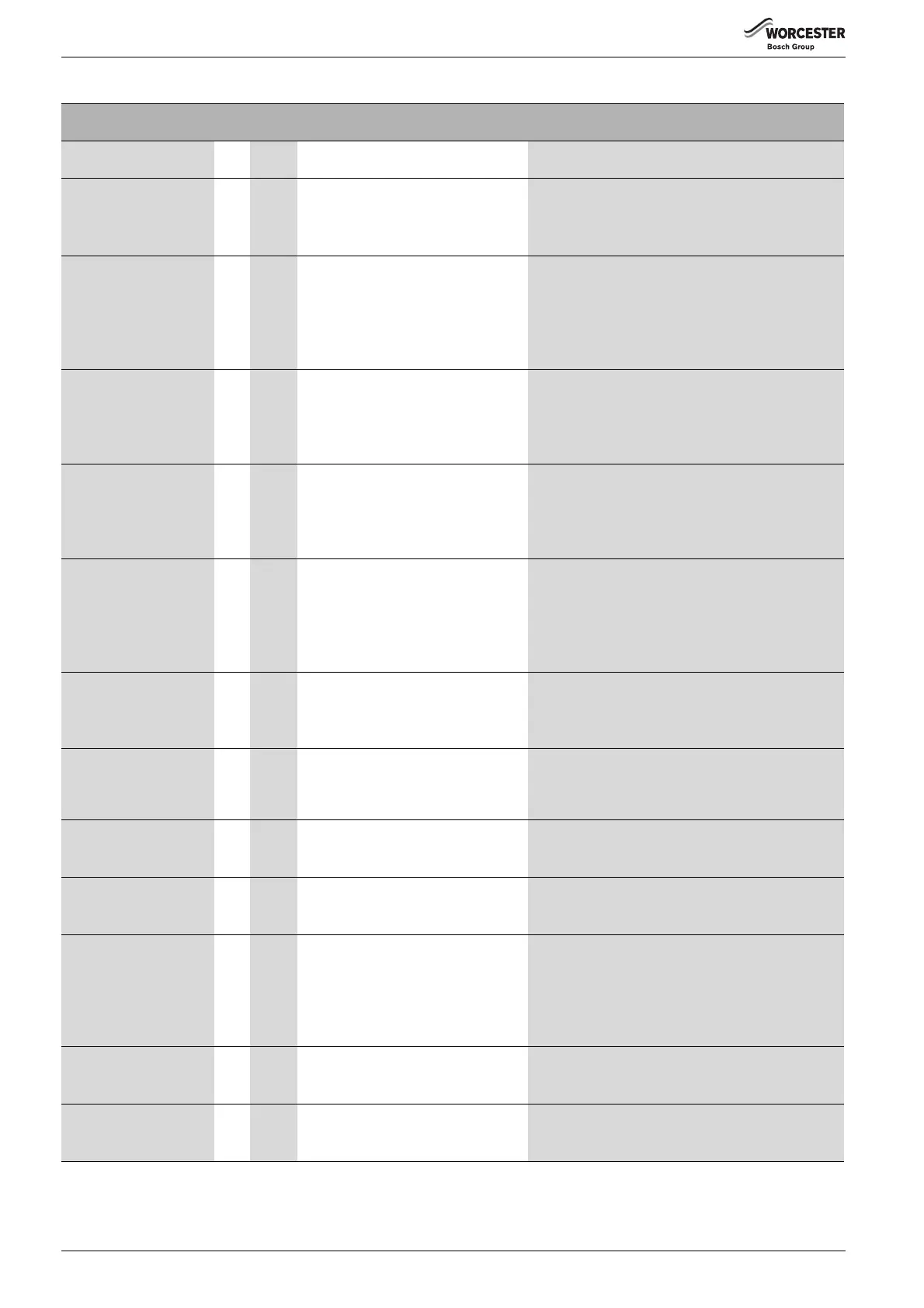

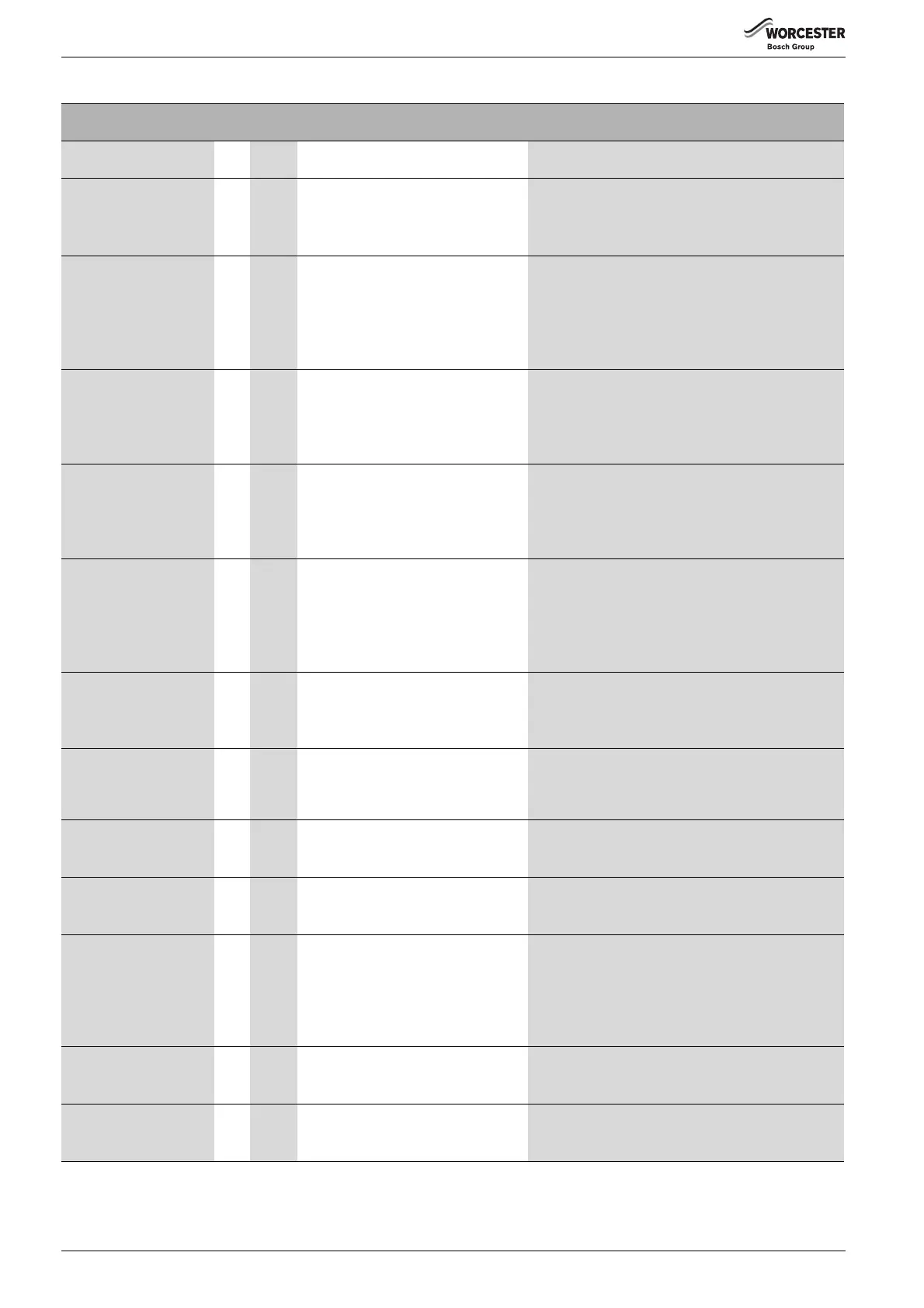

Fault finding and diagnosis

Greenstar i System

ErP

- 6 720 806 945 (2015/07)66

8.1.2 Error codes

Display text

Fault

code

Cause

code

Description Possible solution/check

226 Service tool has been connected In the blocking error history menu it records if the service

tool has been connected

Electrical interruption fault Fd 231 The power has been interrupted during a

lockout

▶ Check locking error history:

– Lockout fault will always be last code before FD

code.

▶ Reset the appliance

Fan/Airflow fault C7 214 Fan does not run during the start up phase ▶Check:

– Fan harness and connector.

– 230 Vac across brown and blue wires.

– Fan operation, replace if necessary.

– Connections of the control box.

▶ Replace control box if necessary.

Fan/Airflow fault C6 215 Fan speed too high ▶Check:

– Fan harness and connector.

– Fan operation, replace if necessary.

– Connections of the control box.

▶ Replace control box if necessary.

Fan/Airflow fault C6 216 Fan speed too low ▶Check:

– Fan harness and connector.

– Fan operation, replace if necessary.

– Connections of the control box.

▶ Replace control box if necessary.

Fan/Airflow fault C7 217 Fan has stopped during appliance

operation

▶Check:

– Fan harness and connector.

– 230 Vac across brown and blue wires.

– Fan operation, replace if necessary.

– Connections of the control box.

▶ Replace control box if necessary.

Fan/Airflow fault C1 264 Fan stopped during operation ▶Check:

– Fan harness and connector.

– 230 Vac across brown and blue wires.

– Operation, replace if necessary.

Fan/Airflow fault C4 273 Continuous fan operation for the last 24

hours (appliance temporary blocked)

▶ Check if demand has been calling for the 24 hours.

Appliance has been blocked from firing for a minimum

of 2 minutes as it has been operated continuously for

24 hours.

Flow sensor fault E2 222 Flow temperature sensor shorted ▶Check:

– Sensor harness and connector.

– Operation, replace if necessary.

Flow sensor fault E2 223 Flow temperature sensor disconnected ▶Check:

– Sensor harness and connector.

– Operation, replace if necessary.

Flow sensor fault E9 276 Primary Flow temperature exceeded 95 °C ▶Check:

– Primary system water pressure.

– For air in the system

– Circulation within heating system.

– Wiring and operation of the pump and flow

temperature sensor, replace part/s if necessary.

Flow sensor fault E2 350 Flow temperature sensor shorted ▶Check:

– Sensor harness and connector.

– Operation, replace if necessary.

Flow sensor fault E2 351 Flow temperature sensor disconnected ▶Check:

– Sensor harness and connector.

– Operation, replace if necessary.

Table 49

Loading...

Loading...