Safety

Operation Manual15

Attachments

Warning

Improper connection of an auxiliary attachment could

result in death or serious injury. Attachments not locked

into place can become unstable and fall on the operator or

other personnel near the forklift.

• Make sure attachment locking devices are always in

place.

• DO NOT operate the forklift until you have positive

indication that the coupler pin and lever are fully

engaged.

• Hydraulic attachments have a maximum hydraulic

pressure rating. Failure to make sure the attachment

is equipped with a pressure reducing valve, or is rated

to be equal or greater than 3,900 psi, which is the

maximum pressure of the forklift auxiliary hydraulic

system at the quick-disconnect couplers, could result in

death or serious injury.

• Make sure all hydraulic connections are tight (if

equipped).

Shut Down Procedure

Warning

To prevent death or serious injury, follow these procedures

before leaving the forklift cab:

• Park forklift on a rm, level surface.

• Move travel select lever to NEUTRAL (N).

• Set parking brake to ON (engaged).

• Lower forks and attachments to the ground.

Always engage the parking

brake before leaving the

forklift. The forklift can roll if

the parking brake is not ON

(engaged), which could result in

death, serious injury, or property damage.

• Turn Ignition switch to the OFF position.

• Remove the key.

• Unbuckle the seat belt.

• Place “Do Not Operate” tags on the Starter switch

and steering wheel when maintenance or service is

required.

• Block wheels when maintenance is required.

Forklift Maintenance

Warning

Follow the manufacturer’s instructions for proper

maintenance to make sure the forklift continues to meet

manufacturer’s specications. Failure to properly maintain

the forklift can result in improper performance, which could

cause death, serious injury, or property damage.

Attach “Do Not Operate” tags to the Ignition

switch and steering wheel before beginning

any service or maintenance.

• “Do Not Operate” tags indicate the forklift should

not be operated until all service or maintenance is

completed.

• Keep two (2) legible “Do Not Operate” tags with the

forklift at all times. “Do Not Operate” tags are provided

at the end of this manual.

• DO NOT operate the forklift and attachments if they

require repairs.

• Make sure basic maintenance is completed and service

problems are corrected.

• Death or serious injury can result from operating a

forklift before all repairs have been made and all prop-

er maintenance is completed.

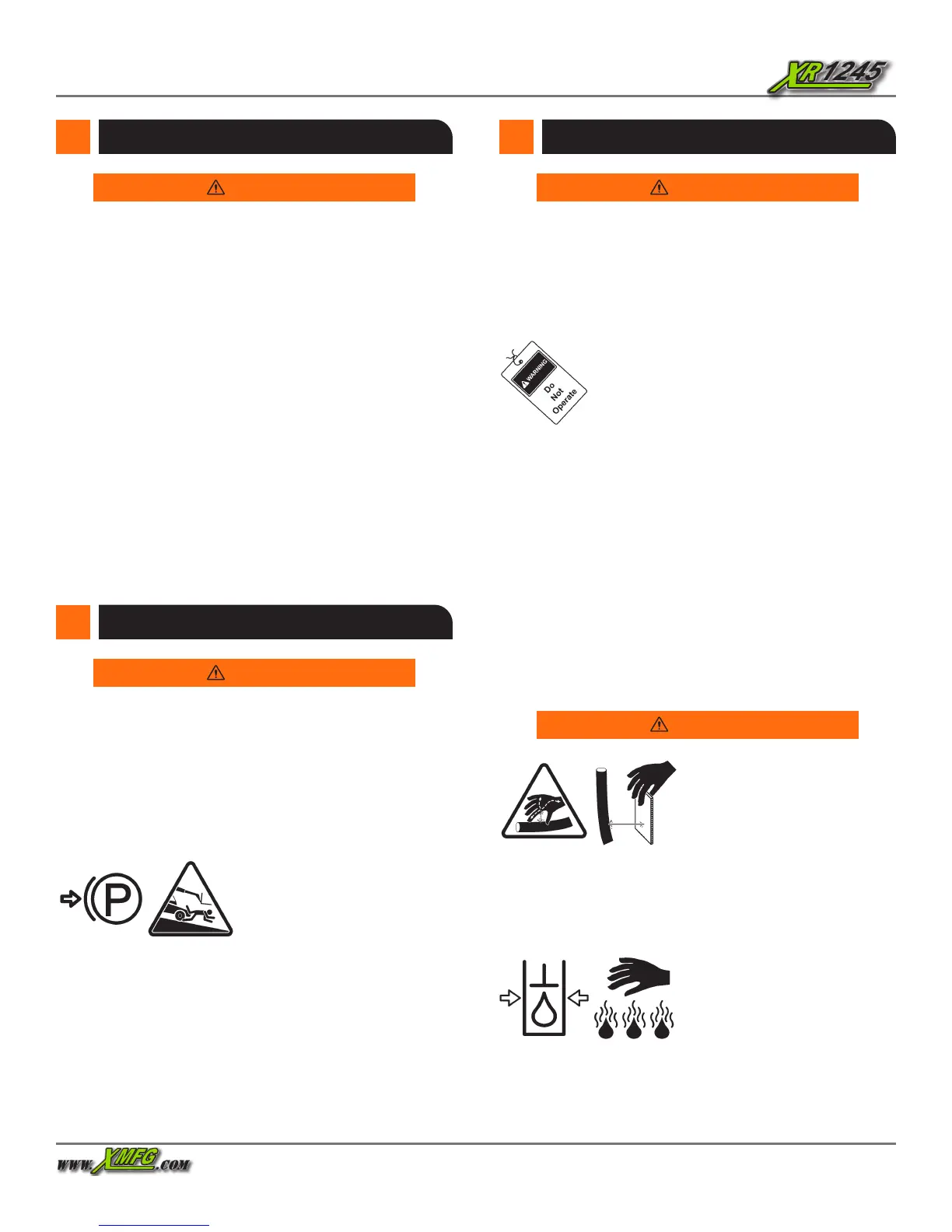

Check hydraulic oil lines, tubes,

and hoses carefully. DO NOT

use your bare hand to check for

leaks. Always use a board or

cardboard when checking for

a hydraulic leak. Escaping hydraulic uid under pressure,

even a pinhole size leak, can penetrate body tissue, which

could cause death or serious injury. If hydraulic oil is inject-

ed into your skin, a doctor familiar with this type of injury

must treat it immediately.

Warning

Serious injury could result from

hydraulic oil pressure or hot

oil. DO NOT remove a hydrau-

lic tank ller cap unless it is

cool enough to touch with bare

hands. Remove the hydraulic tank ller cap slowly to relieve

pressure. Relieve all pressure in a hydraulic system before

any caps, lines, ttings, or related items are disconnected

or removed.

Loading...

Loading...