20 Troubleshooting

YASKAWA TOEPC7106171FD FP605 DRIVE INSTALLATION & PRIMARY OPERATION 115

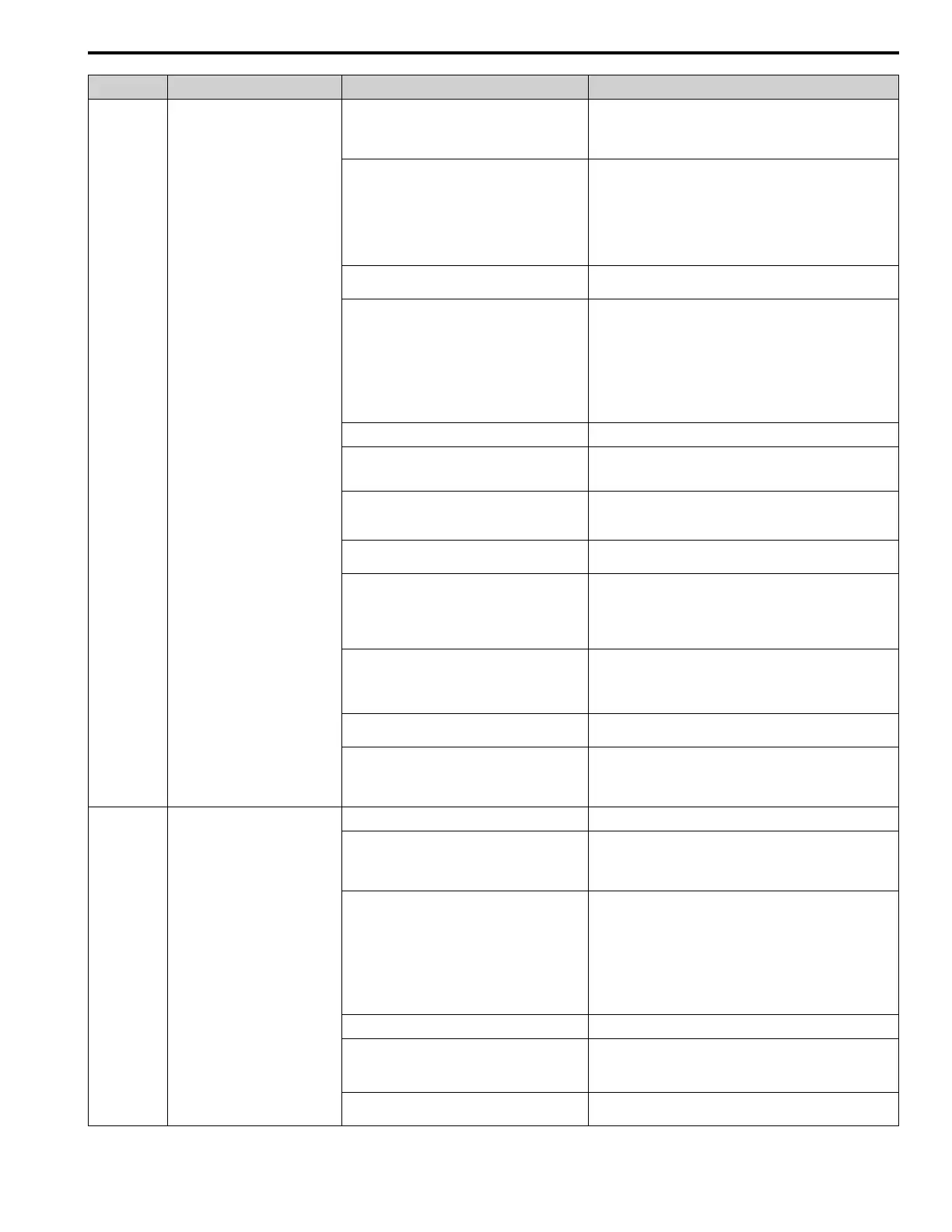

Code Name Causes Possible Solutions

The acceleration/deceleration times or cycle times are

too short.

• Examine the acceleration/deceleration times and the motor start/

stop frequencies (cycle times).

• Increase the values set in C1-01 to C1-04 [Acceleration/

Deceleration Times].

Overload occurred while running at low speed. • Decrease the load when running at low speed.

• Increase the motor speed.

• If the motor is run frequently at low speeds, replace the motor

with a larger motor or use a drive-dedicated motor.

Note:

For general-purpose motors, overload can occur while running

at low speed when operating at below the rated current.

L1-01 [Motor Overload (oL1) Protection] is set

incorrectly.

Set L1-01 in as specified by the motor qualities for a drive-dedicated

motor.

The V/f pattern does not fit the motor qualities. • Examine the ratios between the V/f pattern frequency and

voltage. Decrease the voltage if it is too high compared to the

frequency.

• Adjust E1-04 to E1-10 [V/f Pattern Parameters]. For motor 2,

adjust E3-04 to E3-10. Decrease the values set in E1-08 [Mid

Point A Voltage] and E1-10 [Minimum Output Voltage].

Note:

If the values set in E1-08 and E1-10 are too low, the overload

tolerance will decrease at low speeds.

E1-06 [Base Frequency] is set incorrectly. Set E1-06 to the rated frequency shown on the motor nameplate.

One drive is operating more than one motor. Set L1-01 = 0 [Motor Overload (oL1) Protection = Disabled],

connect thermal overload relay to each motor to prevent damage to

the motor.

The electronic thermal protector qualities and the

motor overload properties do not align.

• Examine the motor qualities and set L1-01 [Motor Overload

(oL1) Protection] correctly.

• Connect a thermal overload relay to the motor.

The electronic thermal protector is operating at an

incorrect level.

Set E2-01 [Motor Rated Current (FLA)] correctly to the value

specified by the motor nameplate.

There is increased motor loss from overexcitation

operation.

• Lower the value set in n3-13 [OverexcitationBraking (OEB)

Gain].

• Set L3-04 ≠ 4 [Stall Prevention during Decel ≠ Overexcitation/

High Flux].

• Set n3-23 = 0 [Overexcitation Braking Operation = Disabled].

The speed search-related parameters are set

incorrectly.

• Examine the settings for all speed search related parameters.

• Adjust b3-03 [Speed Search Deceleration Time].

• Set b3-24 = 1 [Speed Search Method Selection = Speed

Estimation] after Auto-Tuning.

Phase loss in the input power supply is causing the

output current to change.

Make sure that there is no phase loss, and repair problems.

Overload occurred during overexcitation deceleration. • Decrease the value set in n3-13 [OverexcitationBraking (OEB)

Gain].

• Decrease the value set in n3-21 [HSB Current Suppression

Level].

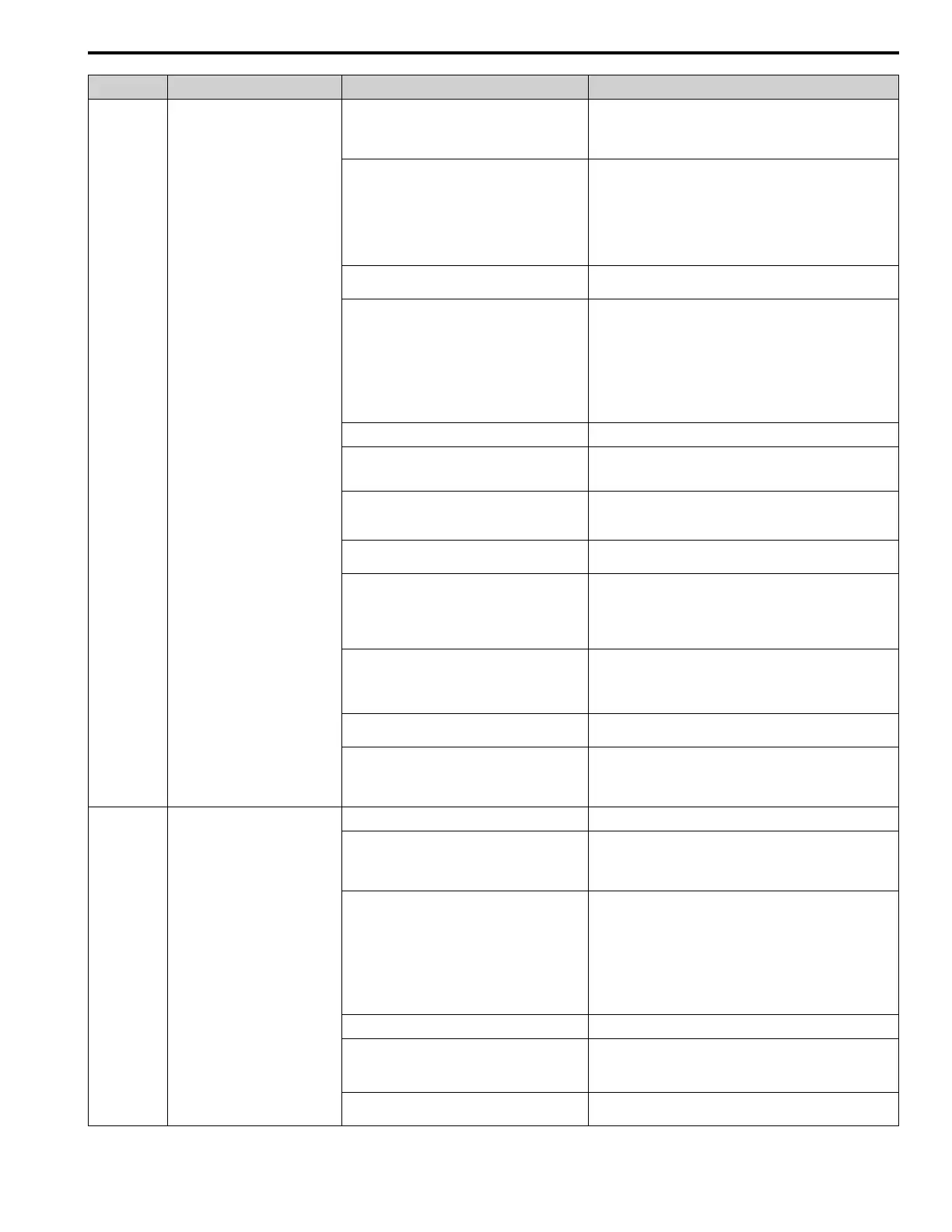

oL2 Drive Overload

The load is too large. Decrease the load.

The acceleration/deceleration times or cycle times are

too short.

• Examine the acceleration/deceleration times and the motor start/

stop frequencies (cycle times).

• Increase the values set in C1-01 to C1-04 [Acceleration/

Deceleration Times].

The V/f pattern does not fit the motor qualities. • Examine the ratios between the V/f pattern frequency and

voltage. Decrease the voltage if it is too high compared to the

frequency.

• Adjust E1-04 to E1-10 [V/f Pattern Parameters]. Decrease the

values set in E1-08 [Mid Point A Voltage] and E1-10 [Minimum

Output Voltage]. For motor 2, adjust E3-04 to E3-10.

Note:

If the values set in E1-08 and E1-10 are too low, the overload

tolerance will decrease at low speeds.

The drive capacity is too small. Replace the drive with a larger capacity model.

Overload occurred while running at low speed. • Decrease the load when running at low speed.

• Replace the drive with a larger capacity model.

• Decrease the value set in C6-02 [Carrier Frequency Selection].

The torque compensation gain is too large. Decrease the value set in C4-01 [Torque Compensation Gain] to

make sure that the motor does not stall.

Loading...

Loading...