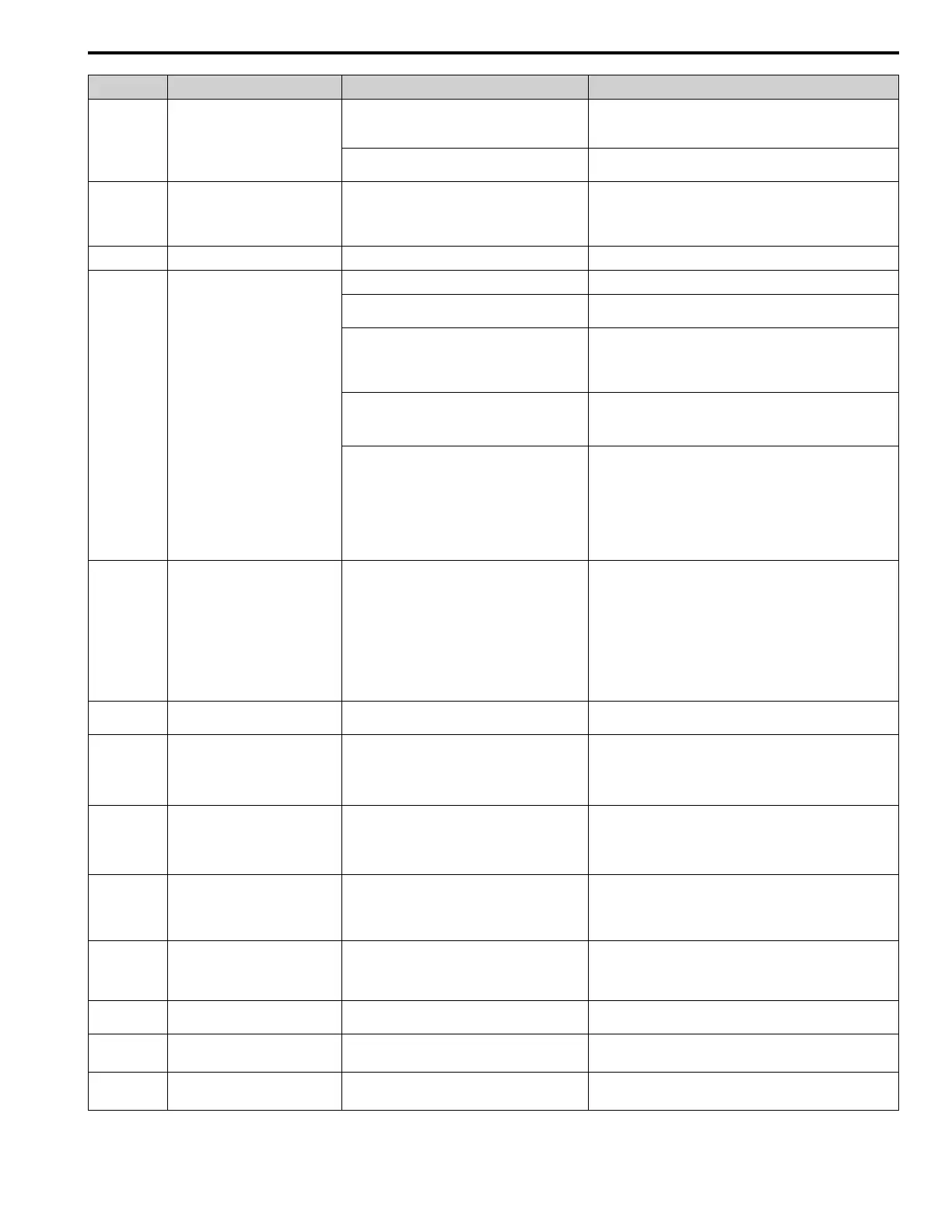

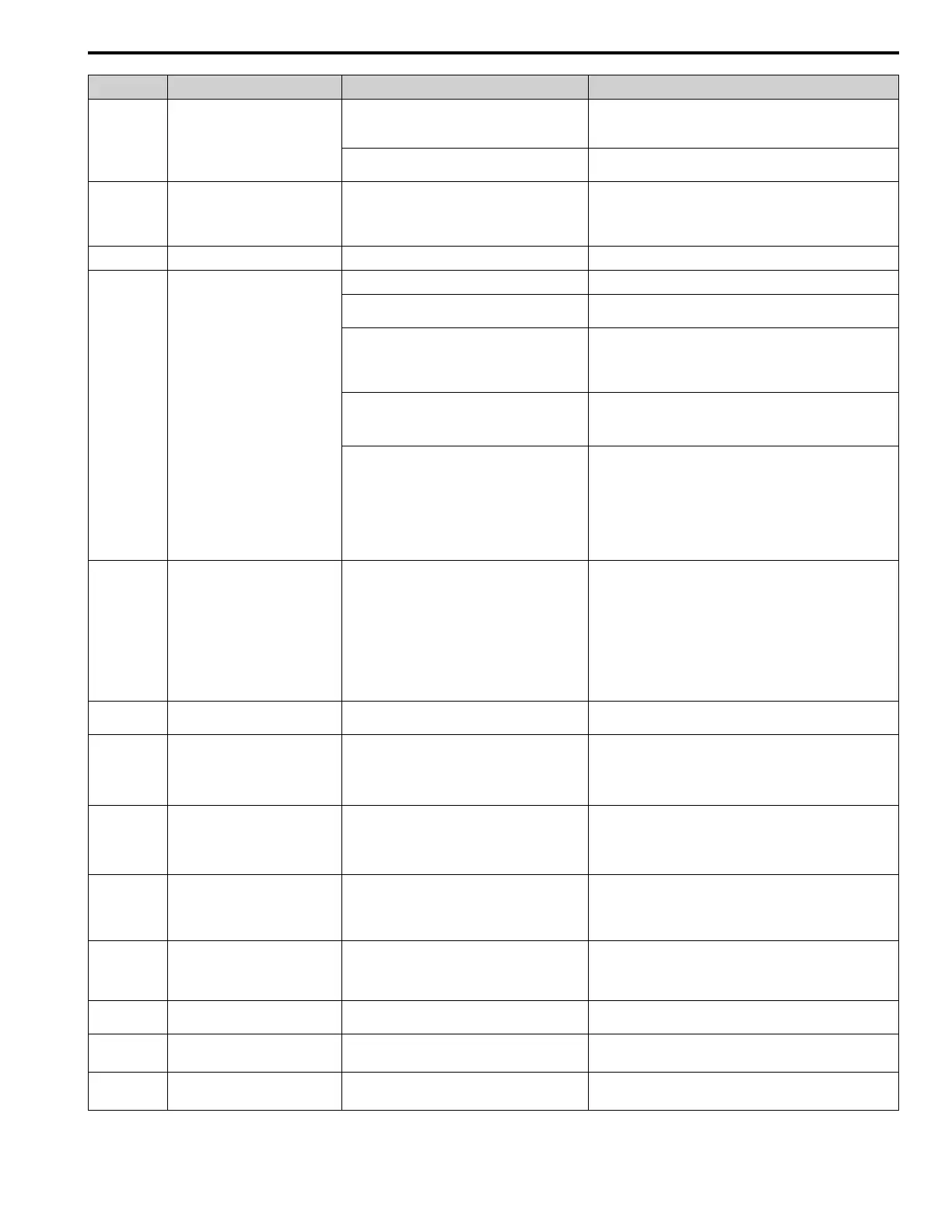

20 Troubleshooting

YASKAWA TOEPC7106171FD FP605 DRIVE INSTALLATION & PRIMARY OPERATION 117

Code Name Causes Possible Solutions

There is motor hunting. • Adjust n1-02 [Hunting Prevention Gain Setting] settings.

• Adjust n8-45 [Speed Feedback Detection Gain] and n8-47 [Pull-

in Current Comp Filter Time] settings.

Speed search does not complete at start when you use

an induction motor in EZOLV control.

When E9-01 = 0 [Motor Type Selection = Induction (IM)], set b3-

24 = 2 [Speed Search Method Selection = Current Detection 2].

ov2 DC Bus Overvoltage 2

The wiring is too long and DC bus voltage is too

large.

• Shorten the shielded motor cable.

• Decrease the carrier frequency.

• If the power supply has a neutral ground, switch on the internal

EMC filter.

PE1, PE2 PLC Faults

The communication option detected a fault. Refer to the manual for the communication option card.

PF Input Phase Loss

There is a phase loss in the drive input power. Correct errors with the wiring for main circuit drive input power.

There is loose wiring in the drive input power

terminals.

Tighten the terminal screws to the correct tightening torque.

The drive input power voltage is changing too much. • Examine the input power for problems.

• Make the drive input power stable.

• If the input power supply is good, examine the magnetic

contactor on the main circuit side for problems.

There is unsatisfactory balance between voltage

phases.

• Examine the input power for problems.

• Make the drive input power stable.

• Set L8-05 = 0 [Input Phase Loss Protection Sel = Disabled].

The main circuit capacitors have become

unserviceable.

• Examine the capacitor maintenance time in monitor U4-05

[CapacitorMaintenance]. If U4-05 is more than 90%, replace the

control board or the drive. For information about replacing the

control board, contact Yaskawa or your nearest sales

representative.

• If drive input power is correct and the fault stays, replace the

control board or the drive. For information about replacing the

control board, contact Yaskawa or your nearest sales

representative.

PSE JOHB-SMP3 Protocol Set Error

• The DIP switches on the JOHB-SMP3 Multi-

Protocol Ethernet Card are at factory default

settings.

• The DIP switches on the JOHB-SMP3 are not set

to a valid protocol.

Remove power from the drive, wait for the charge light to go out,

then set the DIP switches on the JOHB-SMP3 to the desired

protocol.

Note:

• Refer to the instructions packaged with the JOHB-SMP3 for

more information about DIP switch settings.

• “PSE” error occurs only for PRG: 01012 and later, and only

when DIP switches are at their factory default setting.

The “PRG” column on the nameplate on the right side of the

drive identifies the software version. You can also use U1-25

[SoftwareNumber FLASH] to identify the software version.

SC Short Circuit/IGBT Failure

Overheating caused damage to the motor or the motor

insulation is not satisfactory.

Measure the motor insulation resistance, and replace the motor if

there is electrical conduction or unserviceable insulation.

SCF Safety Circuit Fault

The safety circuit is broken. • Make sure that you ground the drive correctly and re-energize the

drive.

• If the fault stays, replace the control board or the drive. For

information about replacing the control board, contact Yaskawa

or your nearest sales representative.

SEr Speed Search Retries Exceeded

The speed search-related parameters are set

incorrectly.

• Decrease b3-10 [Speed Estimation Detection Gain].

• Increase b3-17 [Speed Est Retry Current Level].

• Increase b3-18 [Speed Est Retry Detection Time].

• Do Auto-Tuning again.

SPCNR Single Phase Converter Not Ready

When YC-14 = 0 [Behavior when SPC is Not Ready

= Coast to Stop - Fault], the digital input set to H1-xx

= BE [MFDI Function Selection = Single Phase

Converter Ready NC] deactivated to show the

attached converter is faulted or not ready.

• Examine the wiring between the drive and converter.

• Examine the error code on converter.

STPo Motor Step-Out Detected

The motor code is set incorrectly for PM Control

Methods.

• Set E5-01 [PM Motor Code Selection] correctly as specified by

the motor.

• For specialized motors, refer to the motor test report and set E5-

xx correctly.

TiM Keypad Time Not Set

There is a battery in the keypad, but the date and time

are not set.

Use the keypad to set the date and time.

UL3 Undertorque Detection 1

A fault occurred on the machine.

Example: There is a broken pulley belt.

Examine the machine and remove the cause of the fault.

UL4 Undertorque Detection 2

A fault occurred on the machine.

Example: There is a broken pulley belt.

Examine the machine and remove the cause of the fault.

Loading...

Loading...