1. The Need for Upgrade

1-2

TI 33K01B10-50E

1.1 System Deterioration Due to Aging

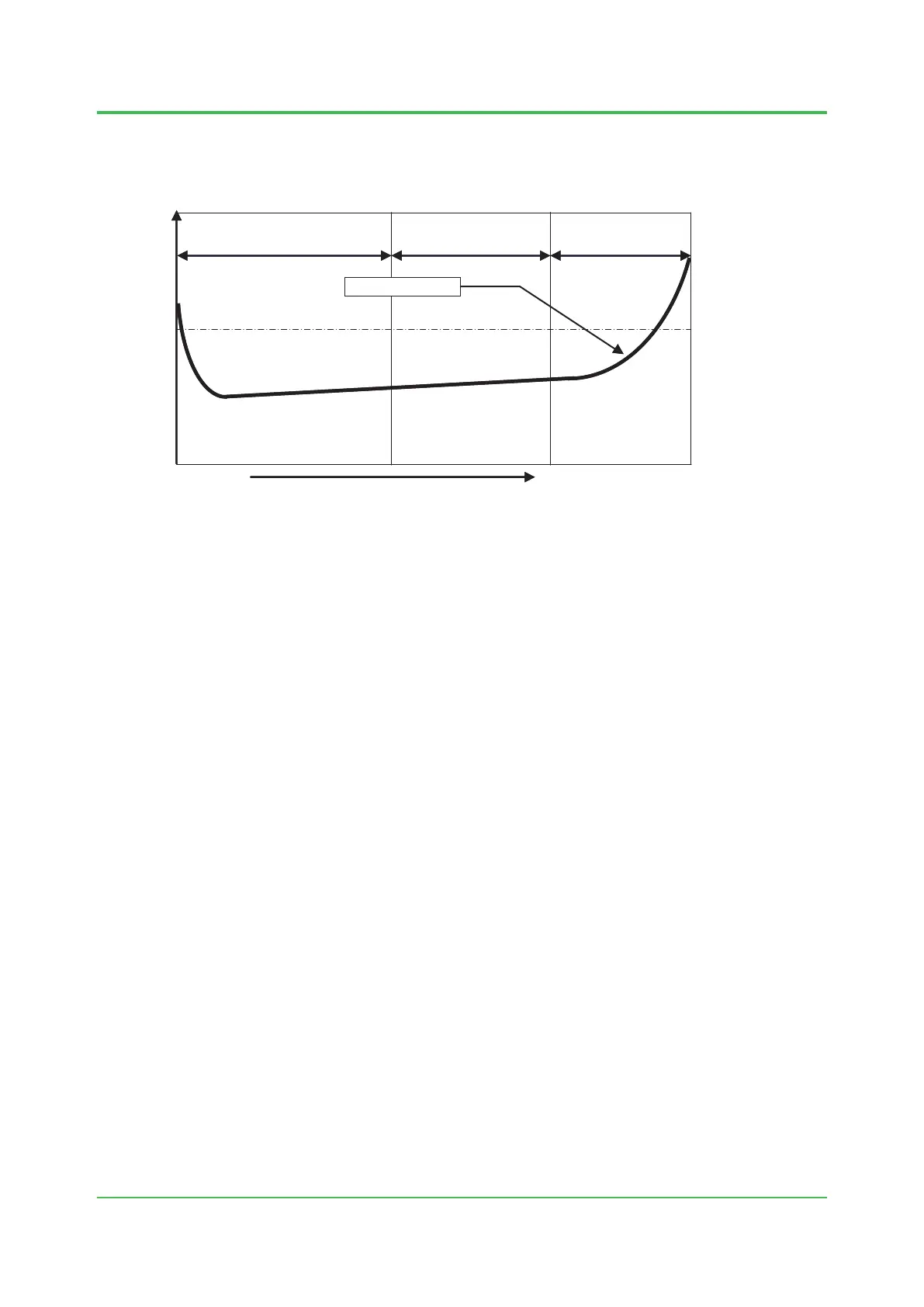

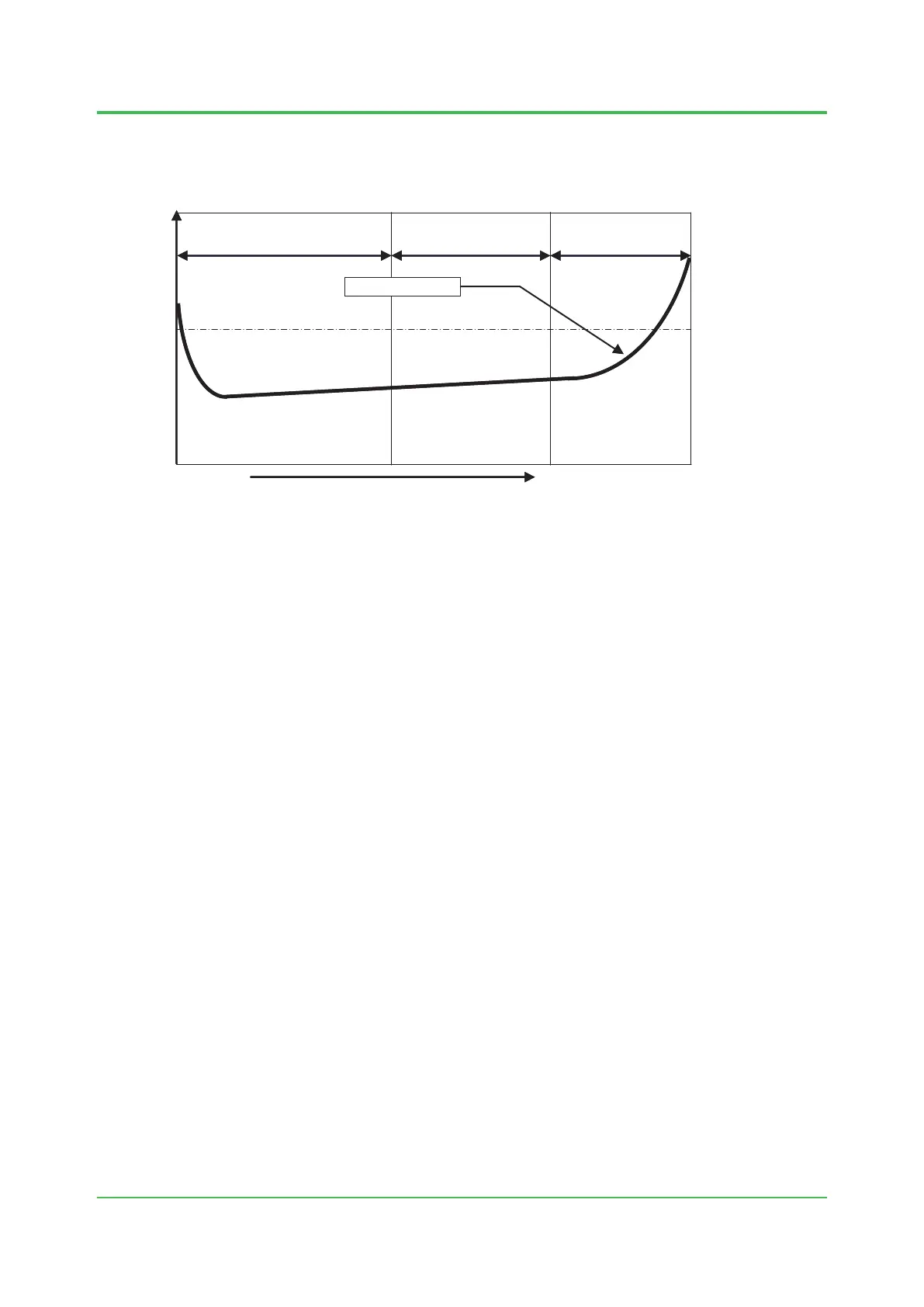

System deterioration can generally be predicted by the so-called bathtub curve as shown in the

followinggure:

Coincident failure cycle

Required reliability

(allowable failure rate)

Shift toward

deterioration cycle

Time

End-of-life cycle

F010101E.EPS

Failure rate (λ)

Deterioration curve

Figure System Deterioration Due to Aging

The failure rate of a system can be taken as a combination of the component parts’ failure rates.

• Temperature:

Failure rate doubles as the temperature rises by 10 °C.

• Humidity:

Corrosive of exposed parts accelerates under a humidity of 60 % or more.

• Corrosivegas:

Corrosive and other reactions occur in the exposed parts.

• Dust:

Short circuits and corrosion are caused.

The failure rate of a system can be taken as the integration of failure rates of its component parts

as follows.

Failurerateofsystem=∑λixNi(λ:failurerateofapart;N:numberofpartsused)

It is empirically ascertained that the ambient conditions largely affect the failure rate of a part as

aforementioned, and the deterioration rate of a system is the sum of the deterioration rates of its

parts.

To minimize the fall in plant operation rate (business loss) caused by aging, costly spare parts

and maintenance checks are necessary.

Mar. 27, 2015-00

Loading...

Loading...