181

JOHNSON CONTROLS

FORM 201.21-NM1 (1223)

In cases where temperature is dropping too fast, when

temperature is within the desired control range, the

Chiller Control Board microprocessor will be required

to make decisions regarding speed changes under

conditions where the “error” and “rate” conict. For

example, the Chiller Control Board microprocessor

may elect to reduce the speed of the compressor(s) if

the error is “0” (temperature is at Setpoint), while the

rate of change of chilled liquid temperature is “negative“

(falling). The Chiller Control Board microprocessor

may also elect to hold capacity when error is “positive”

(temperature is above Setpoint, but not above Setpoint

+ CR) because the rate of change of chilled liquid is

“negative” (falling). TABLE 5 illustrates these

conditions.

OPTIONAL HIGH IPLV CAPACITY CONTROL (CON'T)

(Loading/Unloading and starting additional compressors)

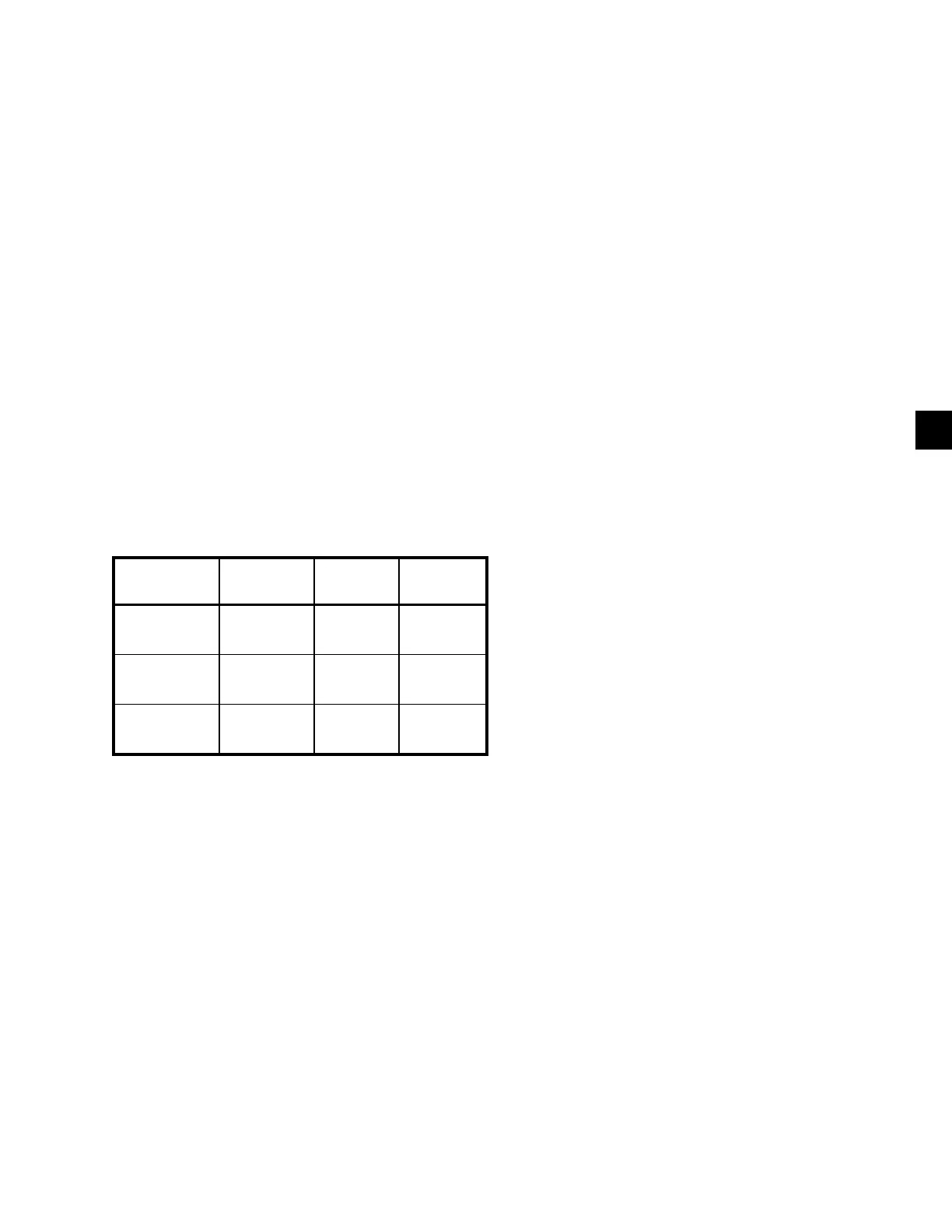

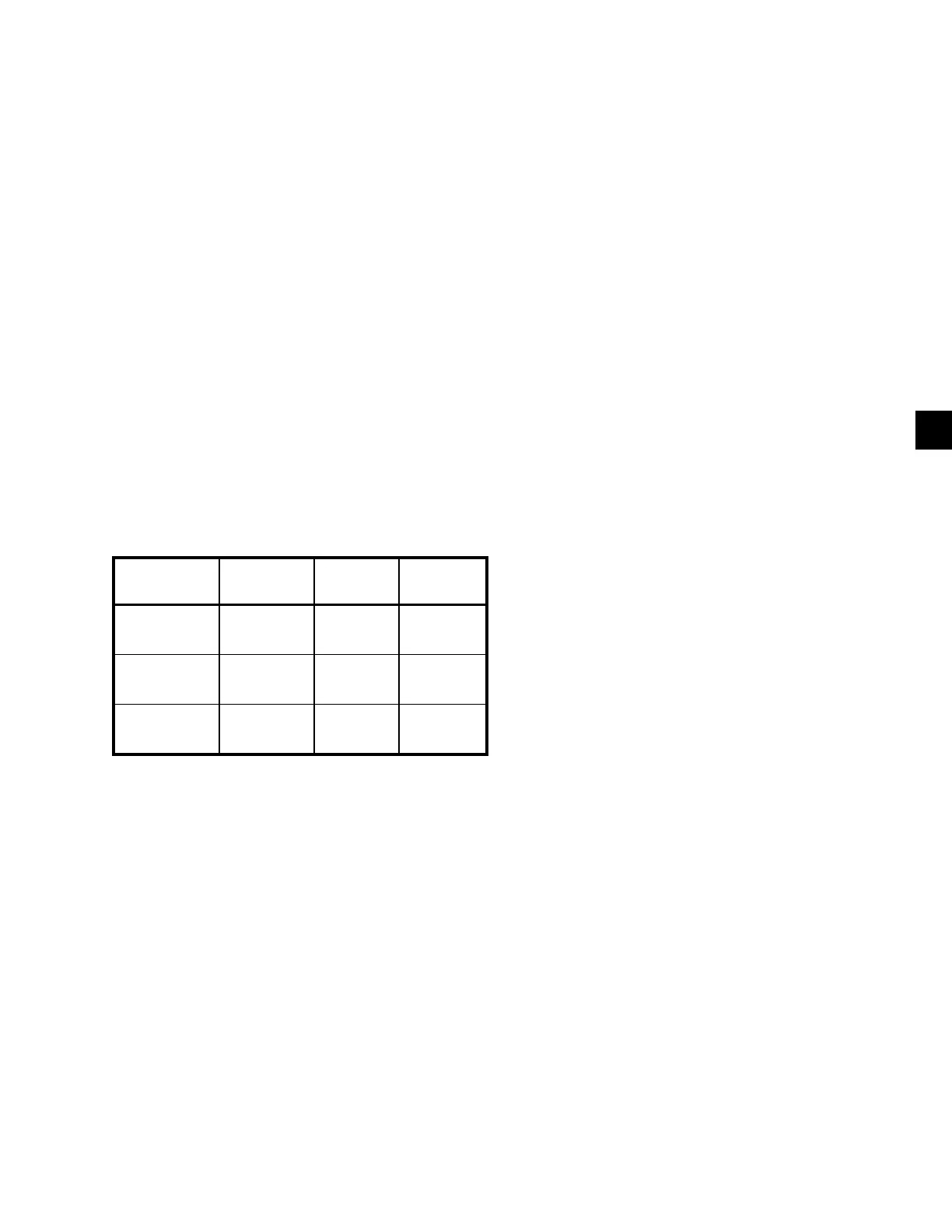

TABLE 5 - FUZZY LOGIC LOADING/UNLOADING

VS. ERROR

NEGATIVE

ERROR

ZERO

ERROR

POSITIVE

ERROR

NEGATIVE

RATE

UNLOAD UNLOAD HOLD

ZERO

RATE

UNLOAD HOLD HOLD

POSITIVE

RATE

HOLD LOAD LOAD

When temperature is signicantly below the Setpoint

– CR/2, the Chiller Control Board microprocessor will

reduce the speed of the compressor(s) to unload the

chiller by 2.0 Hz every 2 seconds. If temperature drops

to within 1.0°F above the Low Chilled Liquid Tempera-

ture Cutout, the Chiller Control Board microprocessor

will unload at the rate of 4.0 Hz every 2 seconds.

As the temperature rises toward Setpoint – CR, the

Chiller Control Board microprocessor’s fuzzy logic will

begin factoring in the rate of change before continuing to

unload. If the rate of change is rising too fast and there

is potential for overshoot, the Chiller Control Board

microprocessor may elect not to decrease speed.

In cases where temperature is rising too fast, when tem-

perature is within the desired control range, the Chiller

Control Board microprocessor will be required to make

decisions regarding speed changes under conditions

where the “error” and “rate” conict. For example, the

Chiller Control Board microprocessor may elect to in-

crease the speed of the compressor(s) if the error is “0”

(temperature is at Setpoint), while the rate of change

of chilled liquid temperature is “positive” (rising). The

Chiller Control Board microprocessor may also elect to

hold capacity when error is “negative” (temperature is

below Setpoint) because the rate of change of chilled

liquid is “positive” (rising). TABLE 5 illustrates these

conditions and the response from the Chiller Control

Board microprocessor.

HOT WATER STARTS

On a hot water start under "best" case conditions, as-

suming power has not been removed and the 120 sec

timer does not inhibit starting, the design of the control

algorithm for a 2 compressor High IPLV leaving chilled

liquid capacity control allows full loading of a chiller in

slightly more than 6 minutes, regardless of the number

of compressors, if all the compressors start at the same

time. This time period assumes load limiting does not

aect the loading sequence and the ambient is above

40°F.

7

Loading...

Loading...