ACS 400 User’s Manual 135

Output signal source selection

It is possible to control both the relay outputs 1 and 2, as well as the analog output from serial

communication channel 1.

Relay outputs can be controlled in the following way:

Step 1: Configure the ACS 400 to supervise the value of any of the parameters 131-133 using the

parameters in group 32

SUPERVISION.

Step 2: Configure a relay output 1 or 2 to respond to the status of one of the supervised

parameters.

The selected relay can now be turned on or off by writing to supervised parameter (131-133) some

value that is either above or below the given supervision limits.

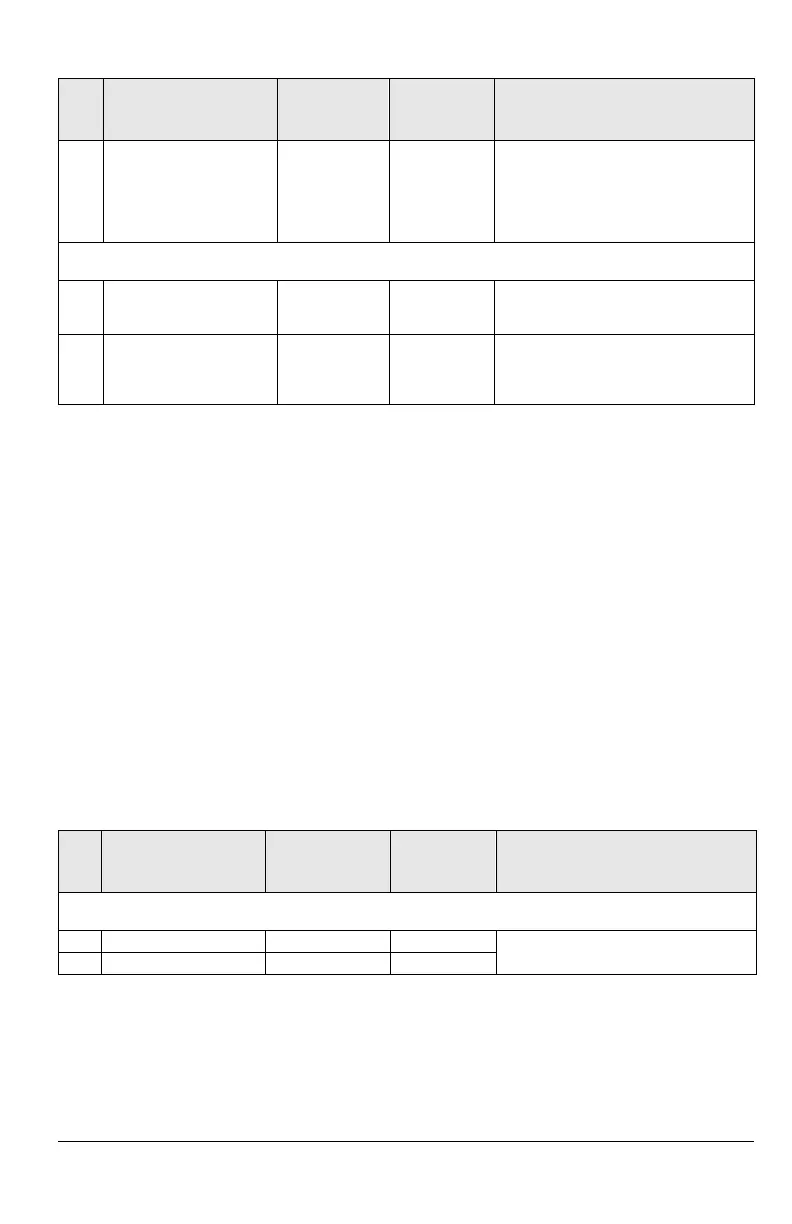

Refer to Table 16 for more information on required parameter settings. With the given settings,

writing any value 100 - 255 to parameter 131

SER LINK DATA 1 causes the relay output 1 to activate.

Writing any value 0 - 99 to parameter 131 causes the relay output 1 to deactivate.

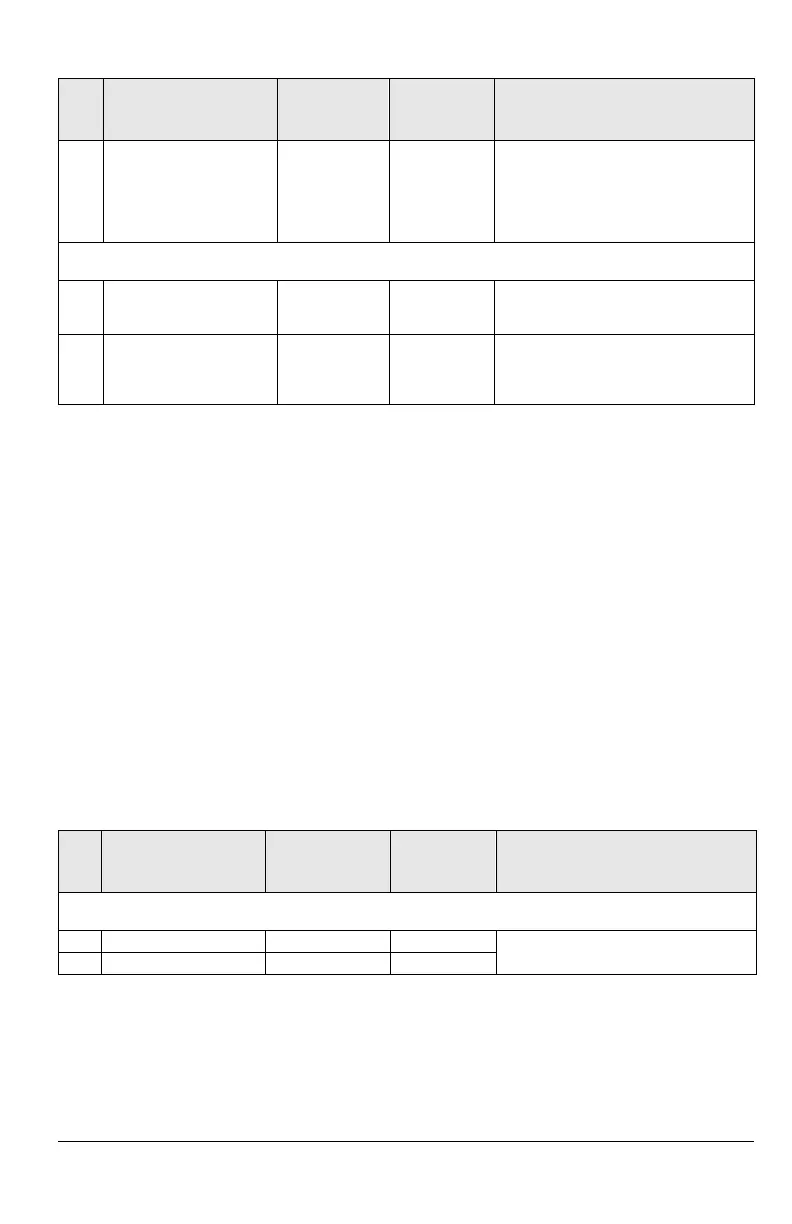

Refer to Table 17 for information on analog output control.

Table 16 Relay output control.

1106 EXT REF2 SELECT 0 = KEYPAD

1 = AI1

...

8 =

COMM

9 = COMM+AI1

10 =

COMM*AI1

8 (

COMM),

9 (

COMM+AI1)

or

10 (

COMM*AI1)

Fieldbus reference 2 is used when EXT2

is selected as control location. See

section References below for information

on the alternative settings.

Group 16

SYSTEM CONTROLS

1601

RUN ENABLE 0 = NOT SEL

1...5 = DI1 ... DI5

6 =

COMM

6 (COMM) The run enable signal is given through

serial communication (Control Word bit

3).

1604

FAULT RESET SEL 0 = KEYPAD ONLY

1...5 = DI1 ... DI5

6 =

START/STOP

7 = COMM

7 (COMM) Fault reset is executed through serial

communication (Control Word bit 7).

Code Parameter Name

Alternative

Settings

Setting for

Standard

Modbus

Function/Information

Group 01

OPERATING DATA

0131

SER LINK DATA 1 0 - 255 - Controlling data for the relay outputs.

0132

SER LINK DATA 20 - 255 -

Code Parameter Name

Alternative

Settings

Setting for

Standard

Modbus

Function/Information

http://nicontrols.com

Loading...

Loading...