ACS 400 User’s Manual 55

Application Macro Factory (1)

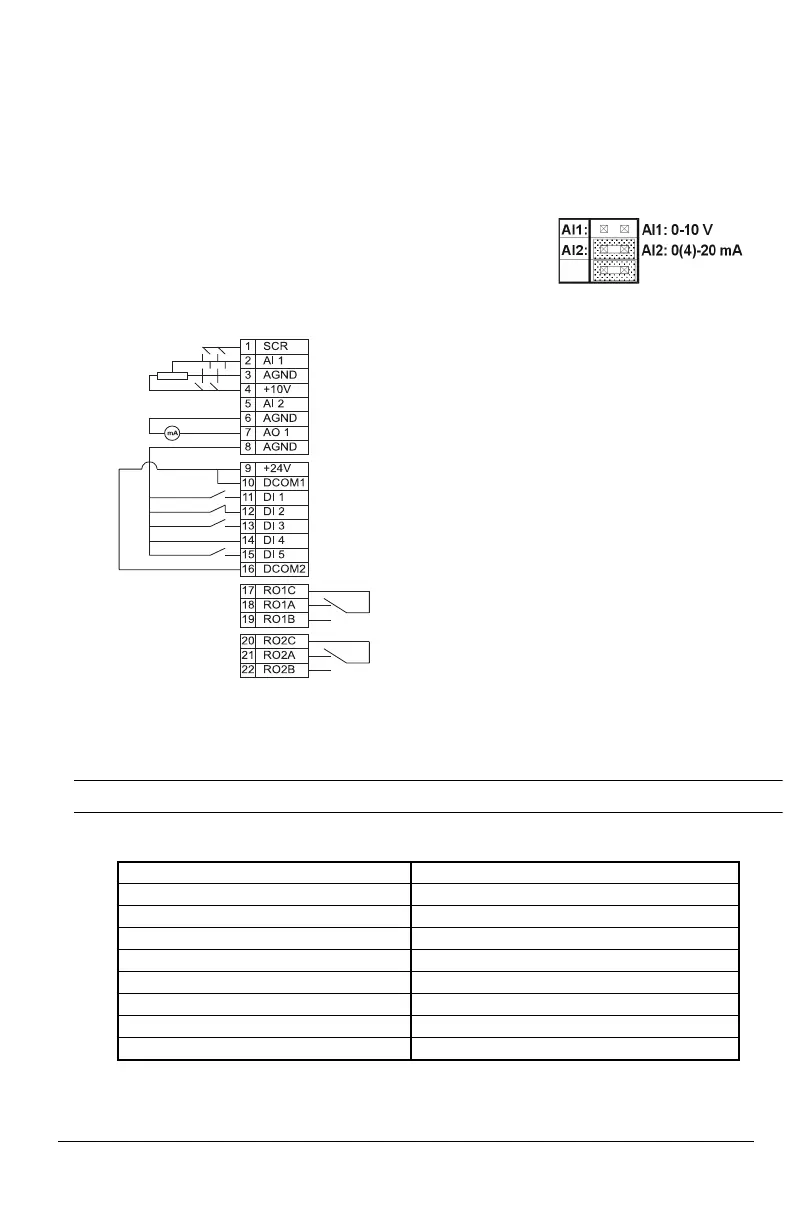

This macro is intended for applications where there is NO control panel available. It provides a

general purpose 3-wire I/O configuration.

The value of parameter 9902 is 0 (

FACTORY). DI 4 is connected.

*Note! DI 4 is used to configure ACS 400. It is read only once when power is connected. All

parameters marked with * are determined by the DI4 input.

Note! Stop input (DI2) deactivated: panel START/STOP button interlocked (local).

Factory (1) parameter values:

Input signals Output signals Jumper Setting

• Start, stop and direction

(DI1,2,3)

• An. output AO:

Frequency

• Analog reference (AI1) • Relay output 1: Fault

• Ramp pair 1/2 selection (DI5) • Relay output 2: Running

* 1001 EXT 1 COMMANDS 4 (DI1P,2P,P) 1402 RELAY OUTPUT 22 (RUN)

1002

EXT 2 COMMANDS 0 (NOT SEL) 1503 AO CONTENT MAX 60 Hz

1003

DIRECTION 3 (REQUEST) 1601 RUN ENABLE 0 (NOT SEL)

1102

EXT1/EXT2 SEL 6 (EXT1) 1604 FAULT RESET SEL 6 (START/STOP)

1103

EXT REF1 SELECT 1 (AI1) 2008 MAXIMUM FREQ 60 Hz

1105

EXT REF1 MAX 60 Hz 2105 PREMAGN SEL 0 (NOT SEL)

1106

EXT REF2 SELECT 0 (KEYPAD) 2201 ACC/DEC 1/2 SEL 5 (DI5)

* 1201 CONST SPEED SEL 0 (NOT SEL) 4001 PID GAIN 1.0

1401

RELAY OUTPUT 1 3 (FAULT (-1)) 4002 PID INTEG TIME 60 s

External Reference 1: 0...10 V <=> 0...50 Hz

Reference voltage 10 VDC

Not used

Output frequency 0...20 mA <=> 0...50 Hz

+24 VDC

Momentary activation with DI2 activated: Start

Momentary deactivation: Stop

Fwd/Rev: activate to reverse rotation direction

Has to be connected!*

Ramp pair selection. Activate to select ramp pair 2.

Relay output 1, programmable

Default operation: Fault => 17 connected to 18

Relay output 2, programmable

Default operation: Running => 20 connected to 22

http://nicontrols.com

Loading...

Loading...