Loading...

Loading...

Do you have a question about the ABB ACS 400 and is the answer not in the manual?

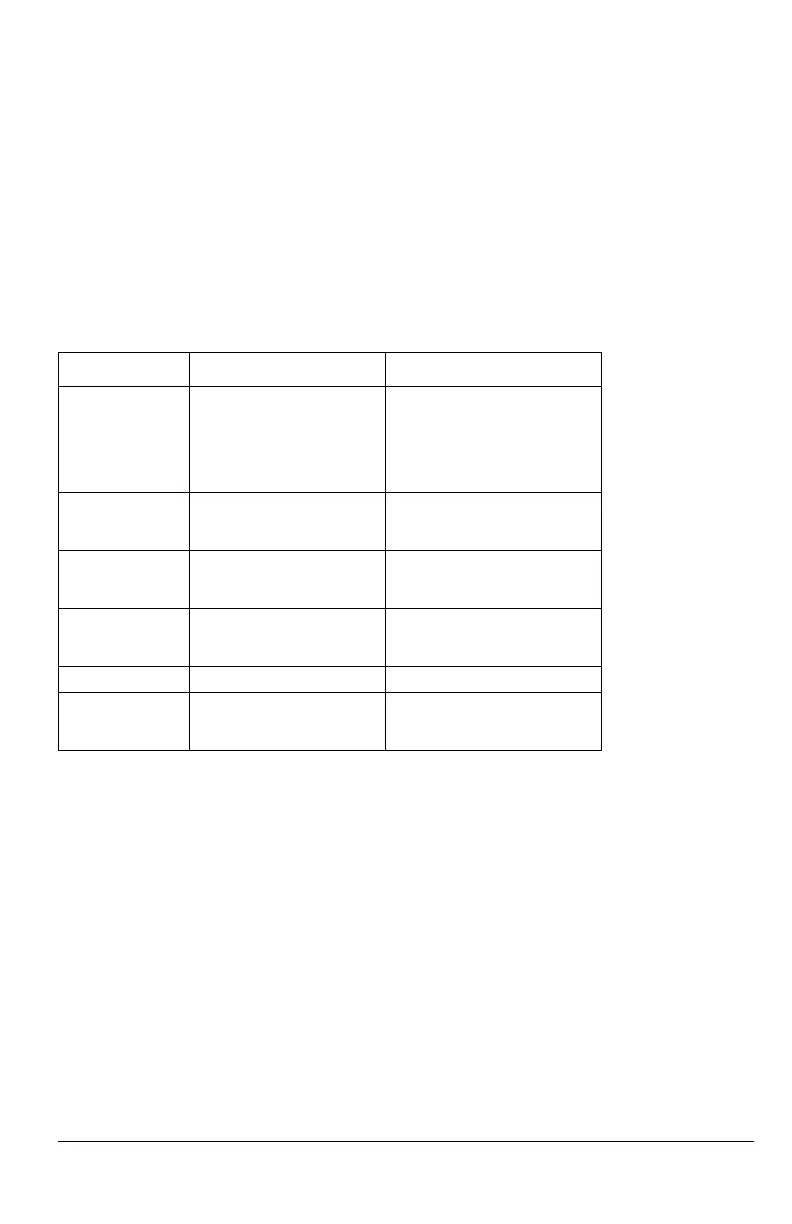

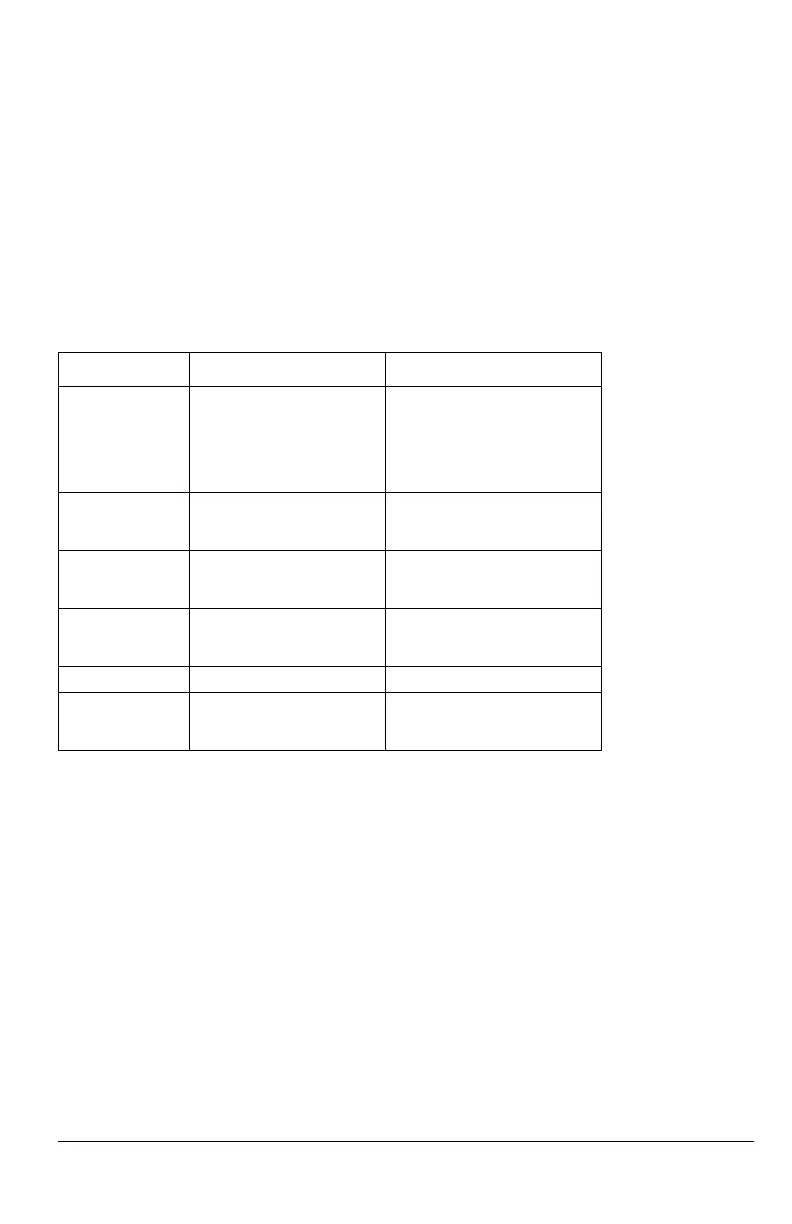

| Brand | ABB |

|---|---|

| Model | ACS 400 |

| Category | Controller |

| Language | English |

Sequence of actions for installing the ACS 400 drive unit.

Detailed guidance on connecting input power, motor, and control wiring.

Specific information about the main I/O terminal X1 and its connections.

Overview of the ACS 400's built-in protective mechanisms and indicators.

How the ACS 400 protects the motor from excessive current and overheating.

How the ACS 400 protects itself from overload conditions based on duty cycle.

Detailed technical specifications for various ACS 400 models and features.

Overview and operation of the ACS-PAN-A control panel for drive configuration.

Procedure for modifying parameter values using the ACS100-PAN.

Steps to clear faults using the ACS100-PAN.

How alarms and faults are indicated and stored on the control panels.

Methods for resetting faults based on LED status and configuration.

Flowchart to diagnose and resolve issues when the motor fails to start.

Flowchart to diagnose and resolve issues where the motor stalls during acceleration.

Flowchart to diagnose and resolve overvoltage faults in the drive.

Flowchart to diagnose and resolve overcurrent faults in the drive.

Flowchart to diagnose and resolve overload faults in the drive.

Flowchart to diagnose and resolve undervoltage faults in the drive.

Flowchart to diagnose and resolve external fault indications.

Flowchart to diagnose and resolve issues where the operator panel shows no display.

Parameters for initial configuration, including language and motor ratings.

Parameters for setting operational limits such as maximum current and frequency.

Parameters defining the drive's start and stop behavior.

Parameters for setting acceleration, deceleration, and ramp shapes.

Parameters that configure the drive's response to various fault conditions.

Parameters for automatically resetting certain types of faults.

Parameters for configuring the drive's Proportional-Integral-Derivative controller.

Second set of PID controller parameters for advanced tuning.

Configuration for a basic 2-wire I/O application macro.

Configuration for a basic 3-wire I/O application macro.

Configuration for a typical 2-wire I/O application macro with preset speeds.

Configuration for a 3-wire I/O application macro using momentary push buttons.

Configuration for an I/O macro alternating drive direction using DI control signals.

Configuration for using digital signals to control motor speed via a potentiometer interface.

Configuration for PID control loops like pressure or flow control.

Configuration for Pump and Fan Control applications.

How drive parameters are mapped to Modbus registers for reading and writing.

Explanation of the Control Word and Status Word for drive operation via Modbus.

Overview of the PFC macro for operating pump/fan stations.

Key features and parameters of the internal PID controller used in PFC macro.