14 ACS 400 User’s Manual

J Cable Connections

Follow local codes for cable size. To avoid electromagnetic interference, use separate conduits for

input power wiring, motor wiring, control and communications wiring, and braking unit wiring. Keep

these four classes of wiring separated in situations where the wiring is not enclosed in conduit. Also

keep 115VAC control wiring separated from low voltage control wiring and power wiring.

Use shielded cable for control wiring.

Use 60 °C rated power cable (75 °C if over 100 amps).

Refer to Section T “Specifications” on page 21 for current, ratings, fuse recommendations and the

maximum wire size capacities and tightening torques for the terminals. The ACS 400 is suitable for

use on a circuit capable of delivering not more than 65,000 RMS symmetrical amperes, 480 V

maximum. The ACS 400 has an electronic motor protection feature that complies with the

requirements of the National Electric Code (USA). When this feature is selected and properly

adjusted, additional overload protection is not required unless more than one motor is connected to

the drive or unless additional protection is required by applicable safety regulations. See

parameters 3004, 3005, and 3006.

For CE installation requirements, see ABB publication CE-US-02 “CE Council Directives and

Variable Speed Drives.” Contact your local ABB representative for specific IEC installation

instructions.

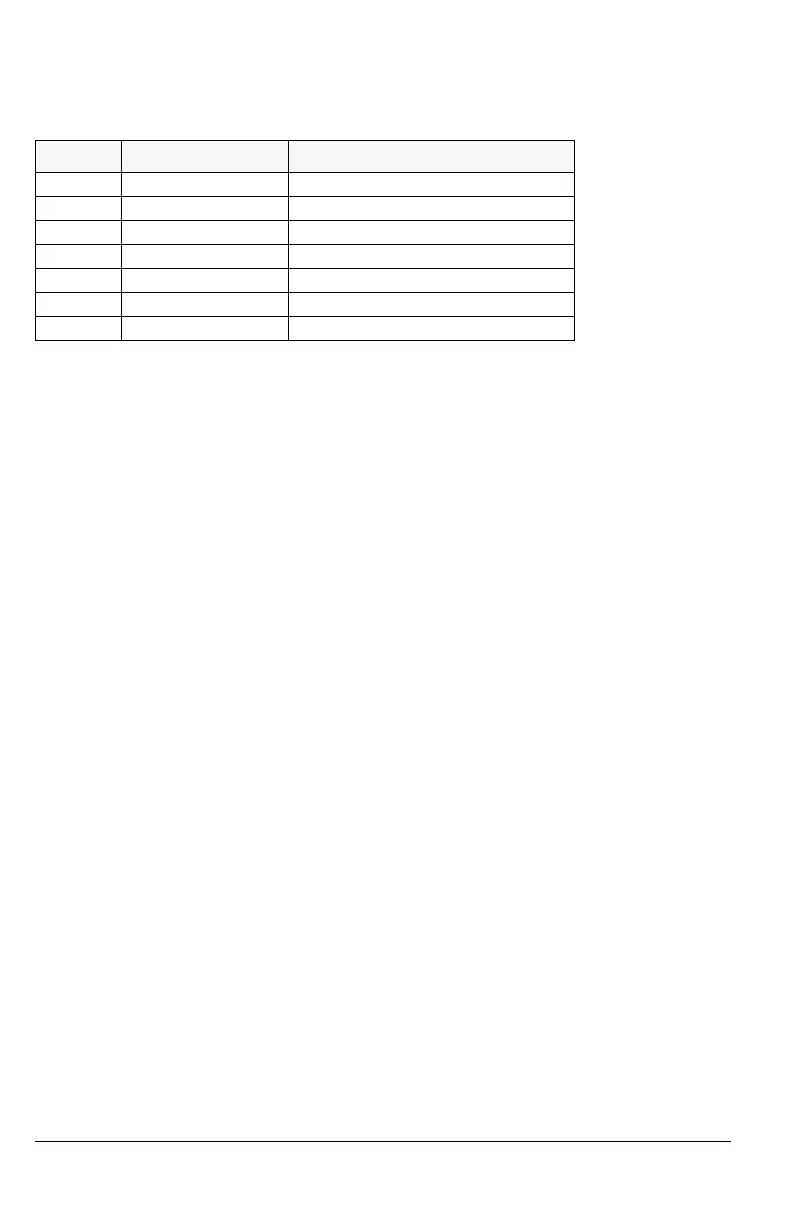

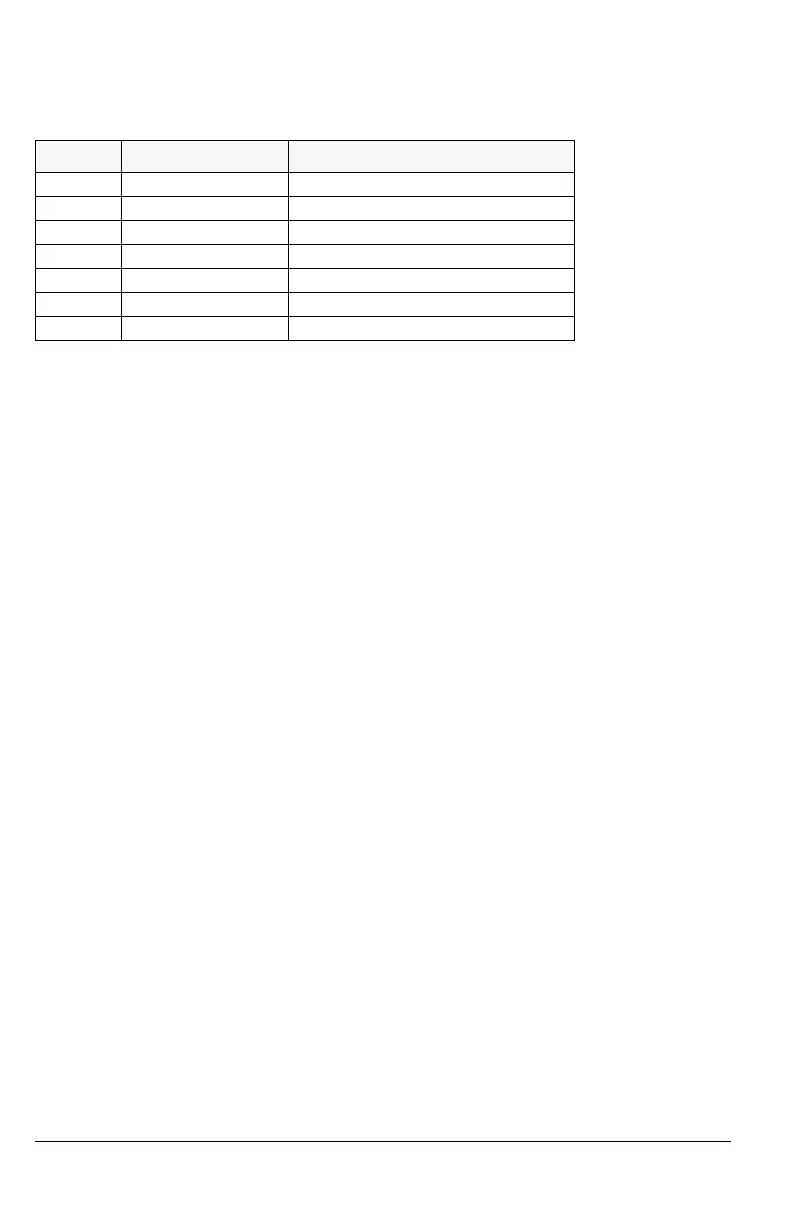

Table 4 Cable

Terminal Description Note

U1, V1, W1 3~ power supply input Do not use 1~ supply!

PE Protective Ground Follow local rules for cable size.

U2, V2, W2 Power output to motor See T.

Uc+, Uc− DC bus For optional ACS-BRK braking unit.

X1 1 to 16 Control Wiring Low voltage control – use shielded cable

X1 17 to 22 Control Wiring Low voltage or 115VAC

X3 RS485 Communications Use shielded cable

http://nicontrols.com

Loading...

Loading...