(5) Mounting the upper diaphragm case

Step Procedure

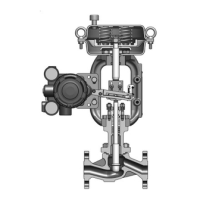

1 Set the upper diaphragm case such that the air pipe connection port is in the position

indicated in

Figure 6-7 to Figure 6-10 (for direct operation models) or the air vent

hole is in the position indicated in

Figure 6-11 to Figure 6-14 (for reverse opera-

tion models). Check that the matching marks that were made before disassembly are

aligned.

2 Tighten the eyebolts alternately and evenly.

3 Secure the upper and lower diaphragm case using hex nuts.

4 Tighten the nuts evenly in a diagonal pattern with the tightening torque indicated in

Table 6-1.

5 For reverse operation actuators, screw the waterproof cap onto the air vent hole of the

upper diaphragm case.

CAUTION

For an actuator that incorporates springs, be sure to follow the

assembly procedure when attaching bolts and nuts. Otherwise,

malfunction may result.

(6) Inspection after reassembly

Step Procedure

1 Apply air at a pressure of 490 kPa to the diaphragm case through the air pipe connec-

tion port of the case. Using soapy water, check the exterior of the diaphragm case (for

direct operation models) or the exterior of the rod (for reverse operation models) for air

leakage.

2 Change the air pressure within the supply air pressure specified for the actuator to check

that the valve moves smoothly for all openings, and that the spring range for a valve

opening is the same as the range printed on the nameplate.

6-11

Loading...

Loading...