Do you have a question about the Beckhoff BC3150 and is the answer not in the manual?

| Brand | Beckhoff |

|---|---|

| Model | BC3150 |

| Category | Controller |

| Language | English |

Information regarding documentation usage, audience, disclaimers, trademarks, and patents.

Essential safety regulations, liability exclusion, personnel qualification, and symbol explanations.

Details on document version history, changes made, and firmware information.

Introduction to BCxx50 controllers, their features, and the basic structure of the Bus Terminal system.

Detailed technical data for BCxx50, PROFIBUS-DP, and PLC functionalities.

Overview of the system, including modularity, mounting, and bus coupler types.

Guidance on mounting the Bus Terminal system components, including dimensions and installation.

Instructions for wiring, covering potential groups, power supply, PROFIBUS, and ATEX conditions.

Describes the sequence of operations and checks performed by the controller upon startup.

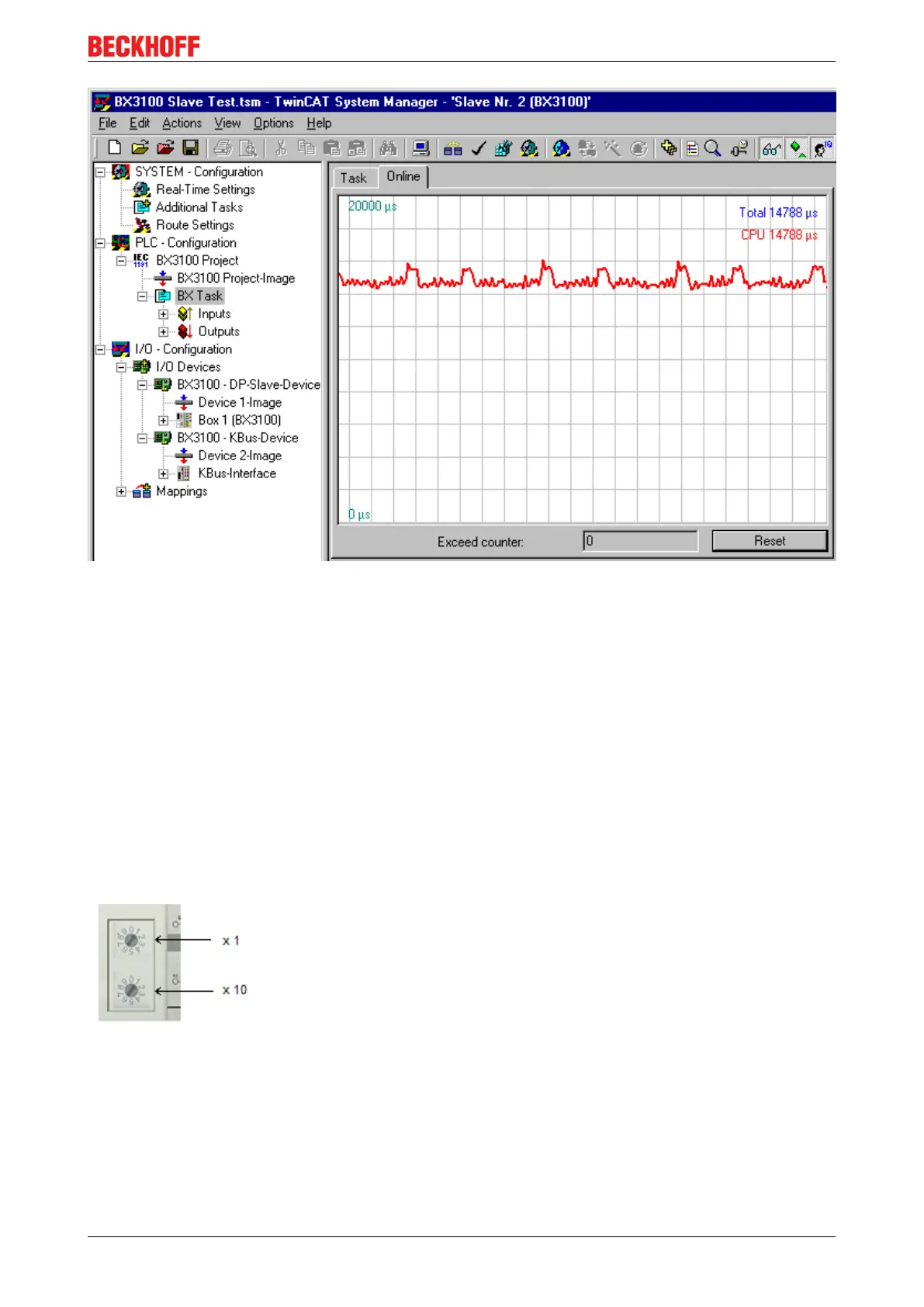

Covers TwinCAT config, ADS, PROFIBUS, K-bus, PLC setup, and slave addressing.

Details on using KS2000 software and the programming cable for setup.

BCxx50 PLC features, TwinCAT PLC introduction, and initial setup.

Managing TwinCAT PLC errors, remanent data, and allocated flags.

Configuring process image, mapping terminals, and creating boot projects.

Methods for program transfer, communication, libraries, and PROFIBUS setup.

Overview of PROFIBUS as an open standard and details on PROFIBUS DP for data exchange.

Explanation of PROFIBUS DPV1 for acyclic telegrams and details on connectors and cables.

Guidelines for PROFIBUS topology and procedures for setting slave addresses.

Methods for diagnosing PROFIBUS state, reading fieldbus status via ADS, and K-bus status.

Explanation of diagnostic LEDs and a table of K-Bus error codes with remedies.

Initial setup guide for BC3150 and instructions for switching between controllers.

Procedures for firmware updates and general operating conditions for fieldbus components.

Test standards for devices and bibliography of relevant technical resources.

List of abbreviations and information on Beckhoff support and service contacts.