Installation 29/60

RE 92801-01-B/11.2018, A15VSO/A15VLO Series 11, BoschRexrothAG

7.3.2 Inside-reservoir installation

NOTICE

Risk ofdamage with inside-reservoir installation!

To prevent damage tothe axial piston unit, all plastic parts (e.g.protective plugs,

covers), except for the tamper-proof caps, must beremoved prior toinstallation

inthe reservoir.

▶ Remove all plastic parts, except for the tamper-proof caps, before you install the

axial piston unit inthe reservoir. Make sure that noparts ofthem remain inthe

reservoir.

▶ Remove the protective plug from the suction portS and open atleast one

Tport.

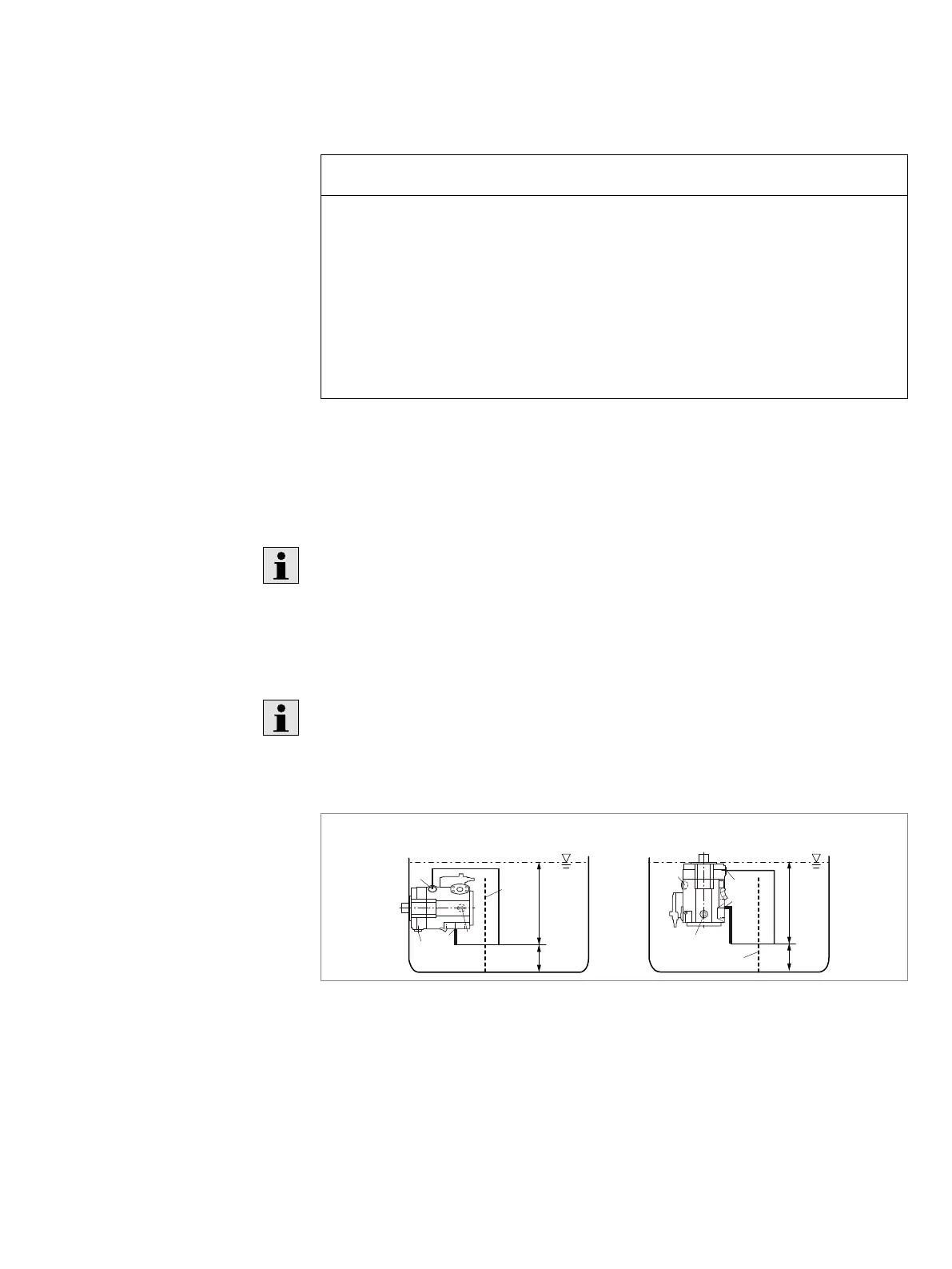

Inside-reservoir installation iswhen the axial piston unit isinstalled inthe reservoir

below the minimum fluid level. The axial piston unit iscompletely below the

hydraulic fluid.

If the minimum fluid level isequal toor below the upper edge ofthepump,

seechapter 7.3.3 "Above-reservoir installation" onpage 30.

Axial piston units with electric components (e.g.electric controls, sensors) must

not beinstalled inareservoir below the fluid level. Exception: Installation

oftheaxial piston unit with E2 /E6 control. However only with Hirschmann

connector and ifmineral hydraulic fluids are used and the fluid temperature inthe

reservoir does not exceed 80 °C.

Our advice istofit asuction pipe tothe suction portS and tofit apipe todrain

portT

1

orT

2

toencase. In this case, the other drain port must beplugged. The

housing oftheaxial piston unit must befilled before fitting the piping and filling

the reservoir with hydraulic fluid.

4 5

S

h

min

h

t min

T

1

T

2

T

3

SB

T

2

h

t min

T

1

T

3

h

min

SB

S

Fig. 10: Tank installation A15VSO/A15VLO with installation position 4–5

T

1

,

T

2

,

T

3

Highest drain port h

t min

Minimum required immersion depth

(200mm)

S Suction port h

min

Minimum required distance

toreservoir bottom (100mm)

SB Baffle (baffle plate)

Loading...

Loading...