Loading...

Loading...

Do you have a question about the Carrier 59TP6B and is the answer not in the manual?

| Stages | Two-stage |

|---|---|

| Blower Motor | Variable-speed |

| Energy Star Certified | Yes |

| Fuel Type | Natural gas |

| Heat Exchanger | Stainless Steel |

| Heating Capacity | 40, 000 - 120, 000 BTUh |

| Warranty | 10-year parts |

Warnings regarding fire, injury, or death hazard when installing in a garage.

Fire hazard warning about prohibited installation configurations.

General guidelines and considerations for furnace venting systems.

Details requirements for venting systems.

Provides maximum allowable vent lengths based on furnace size and altitude.

Fire hazard warning regarding gas valve regulator adjustment.

Procedure for verifying natural gas input rate by clocking the meter.

Adjusting blower airflow for cooling modes.

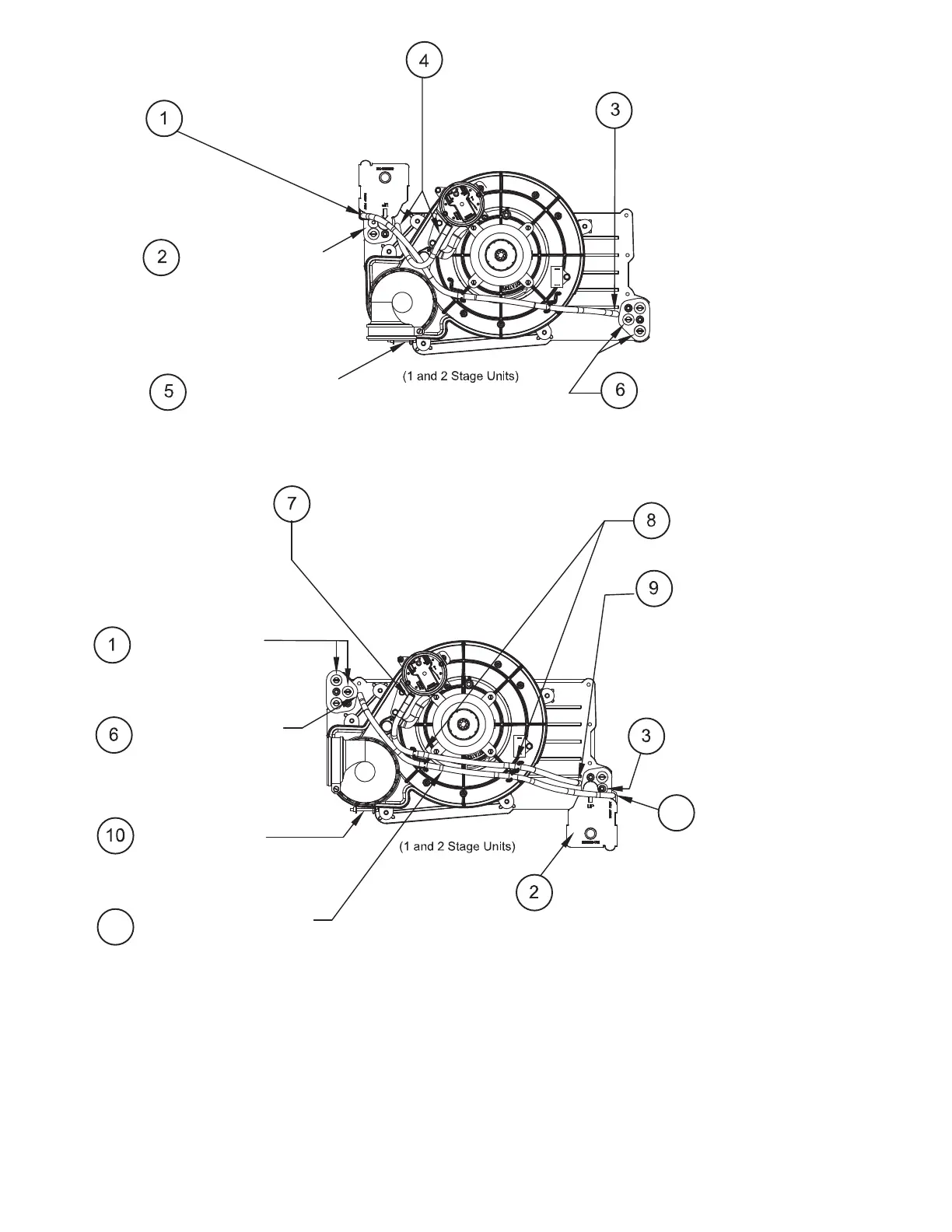

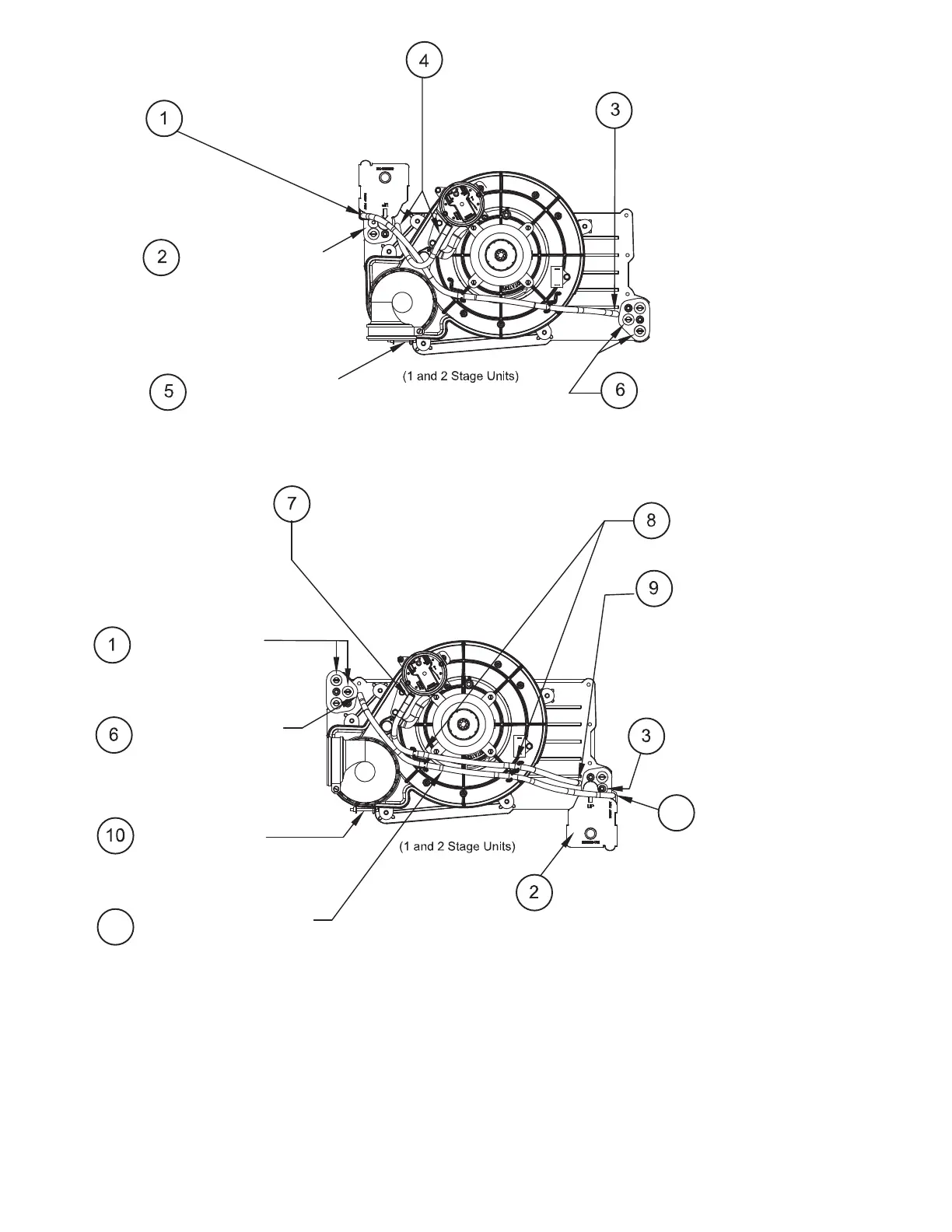

Procedure for testing furnace components.

CO poisoning and fire hazard warning for filter operation.

Procedure for cleaning burners and flame sensor.

Procedure for flushing the collector box and drainage system.

Caution regarding unit and property damage from freezing.

Describes two-stage heating operation with a single-stage thermostat.

Explains the continuous blower mode and its selections.

Warning about using only factory-authorized replacement parts.