4.3 - Free spaces

The free spaces presented are determined in order to ensure

sucient working and manoeuvring space to carry out maintenance

operations on the unit in suitable ergonomic conditions

2523 HT

1500

2200

1500

1500

B

B

B

B C

Key:

All dimensions are given in mm.

B

Clearances required for maintenance and air ow

C

Clearance recommended for coil removal

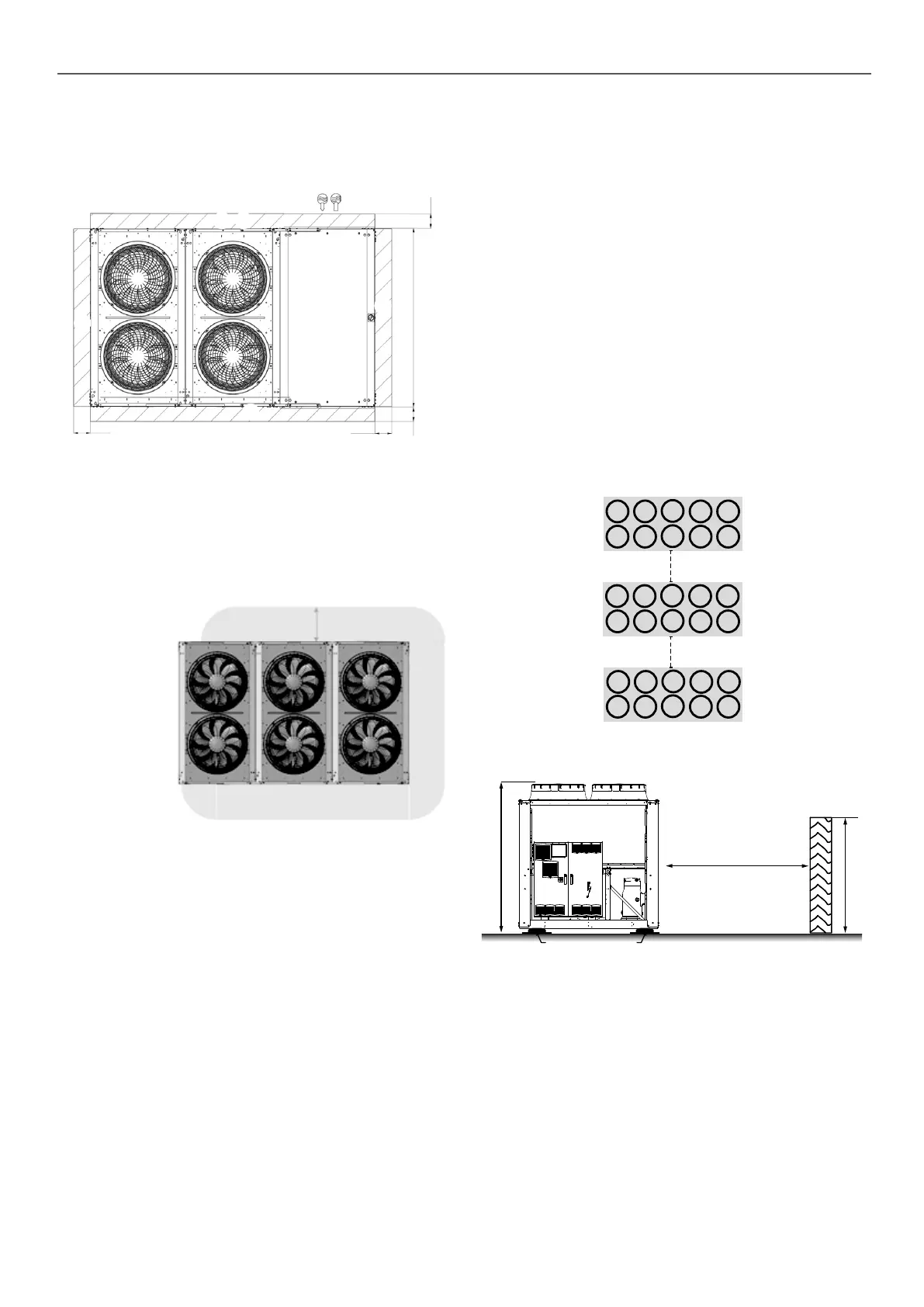

4.4 - Positioning of potentially ammable zones

around the unit

Electrical cabinet side

60cm

The complete unit, including all the options and accessories which

are provided by the manufacturer, have been certied for use with

an A2L refrigerant.

To ensure this, the manufacturer complies with EN 378-2 §6.2.14

and has dened a potentially ammable zone using EN 60079-

10-1 in order to identify where no sources of ignition must be

present.

The manufacturer has then designed the machine so that, if the

unit is used in the manner for which it has been designed, there

are no internal sources of ignition in the potentially ammable

zone inside the machine.

Therefore, the only residual risk is that a source of ignition is

introduced into the potentially flammable zone by the user.

This is why the manufacturer has decided to show the potentially

ammable zone around the machine (see the diagram above)

into which the user must not introduce any sources of ignition.

This indication is only provided to help our customers to identify

the limits of the ammability risk.

However, the machine itself does not present any risk of explosion

connected to the use of A2L refrigerant.

Note (the following information is provided by the manufacturer

for guidance only. The application of the following directives is the

sole responsibility of the user):

In compliance with the directives 2009/104/EC and 1999/92/EC,

these zones may be qualied as ATEX zones by the user on the

basis of their own risk analysis, for which they alone remain

responsible. In accordance with the denition given by Annex I of

the directive 1999/92/EC, this zone may be classied as zone 2

since it may consist of a location where an explosive atmosphere

consisting of a mixture of air and ammable substances in the

form of a gas is not liable to occur during normal operation or, if

it does occur, it only occurs for a short period of time.

If additional equipment is required (motorised valve, pump, etc.),

it must be:

■ Installed outside of the dened potentially ammable zone

■ Certied as not being a source of ignition for the refrigerant

used.

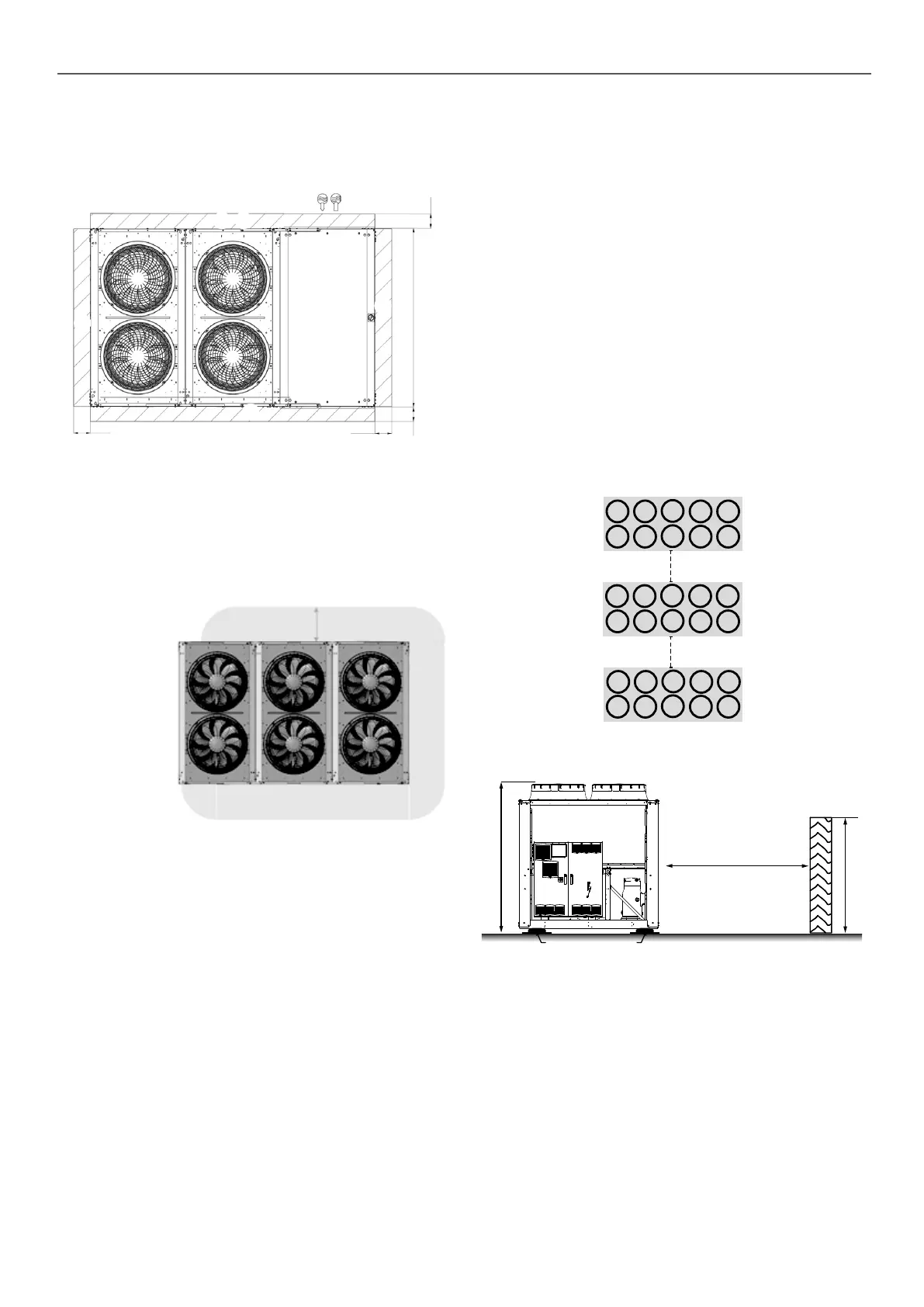

4.5 - Installing several units

It is recommended to install multiple units in a single row, arranged

as shown in the example below, to avoid recycling air between

the units. If the oor space does not allow this arrangement, contact

your distributor to assess the various installation options.

1500 mm min.

1500 mm

min.

4.6 - Distance to the wall

Plots

Antivibratiles

H

S

h

To guarantee correct operation in most cases:

If h < H, S minimum = 3 m

If h > H or S < 3 m, contact your distributor to assess the various

installation options.

4 - DIMENSIONS, CLEARANCES, MINIMUM INSTALLATION DISTANCES

11

Loading...

Loading...