Refrigerant circuit checks:

■ The unit is subject to F-gas tight regulatory checks. Please refer

to the table in the introduction.

■ Check the unit operating parameters and compare them with

the previous values,

■ Check the operation of the high pressure switches. Replace

them if there is a fault,

■ Check the fouling of the dehumidifier filter. Replace it if

necessary,

■ Keep and maintain a maintenance sheet, attached to each

HVAC unit.

IMPORTANT: Ensure all adequate safety measures are taken

for all these operations: use appropriate PPE (personal

protective equipment), comply with all applicable industry

and local regulations, and use common sense.

13.3 - Level 3 maintenance

Maintenance at this level requires specic skills, qualications,

tools and expertise. Only the manufacturer, his representative or

authorised agent are permitted to carry out this work.

This maintenance work relates to the following:

■ Replacement of major components (compressor, water type

heat exchanger),

■ Operations on the refrigerant circuit (handling refrigerant),

■ Modication of factory-set parameters (change of application),

■ Movement or disassembly of the refrigeration unit,

■ Any operation due to proven lack of maintenance,

■ Any operation covered by the warranty,

■ One or two leak detection operations per year performed by

qualied personnel using a certied leak detector.

■ To reduce waste, the refrigerant and the oil must be transferred

in accordance with applicable regulations, using methods that

limit refrigerant leaks and pressure drops and with materials

that are suitable for the products.

■ Any leaks detected must be repaired immediately

■ The compressor oil that is recovered during maintenance

contains refrigerant and must be treated accordingly.

■ Pressurised refrigerant must not be vented to the open air.

■ If the refrigerant circuit must be opened, cap all openings for a

period of up to one day. If open for longer, blanket the circuit

with a dry, inert gas (e.g. nitrogen).

13.4 - Tightening the electrical connections

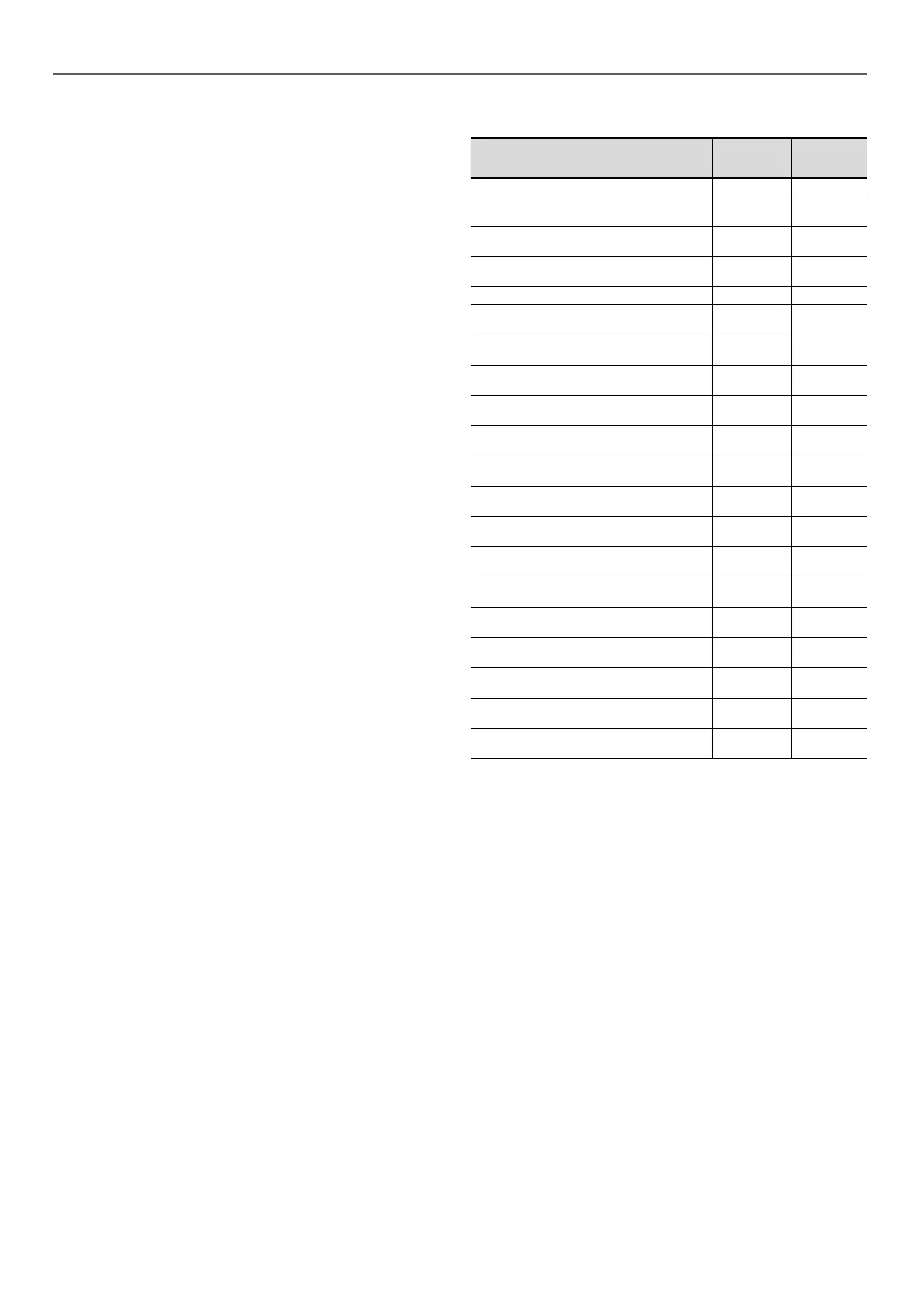

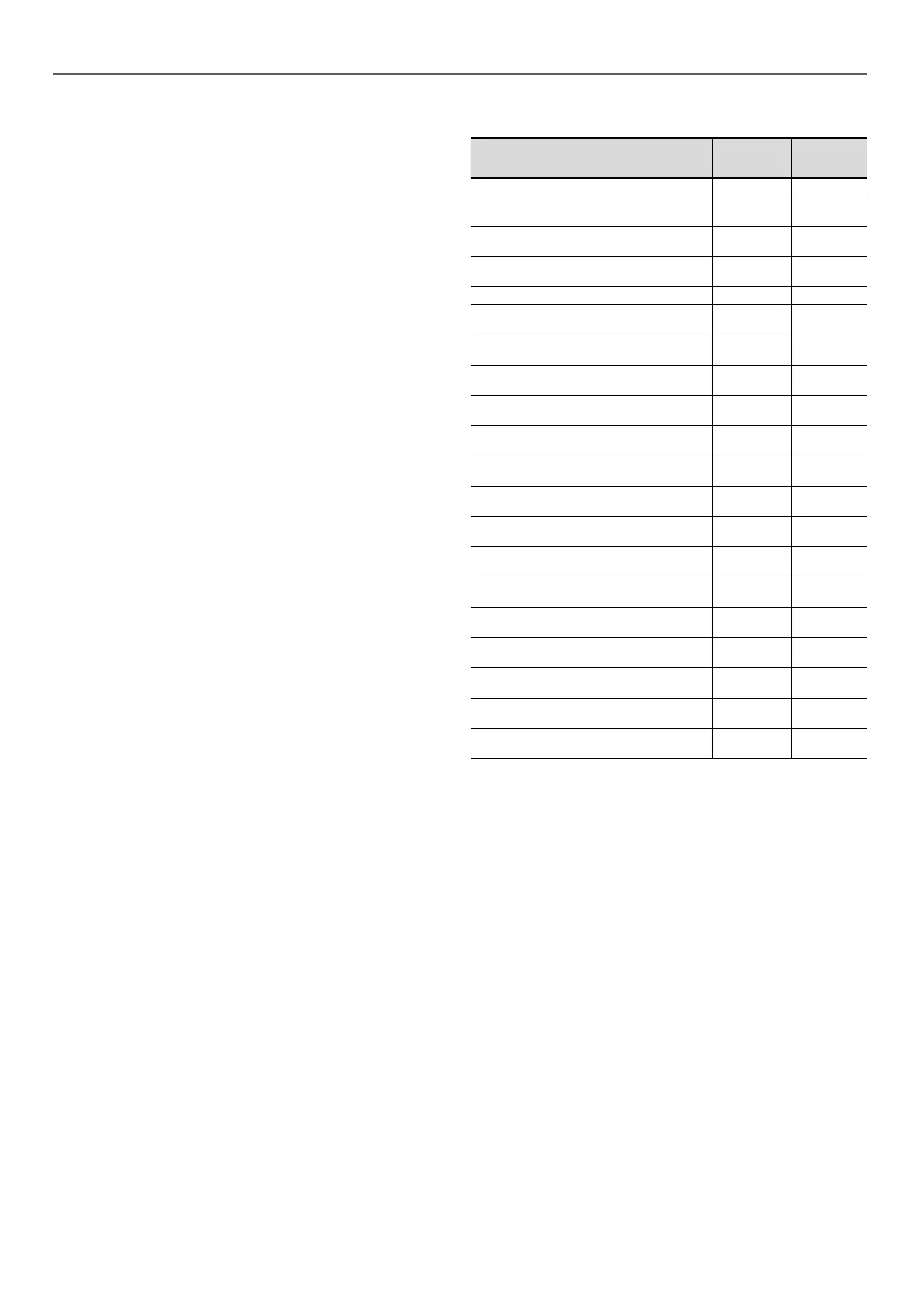

Component Description Value (N.m)

PE welded screw, customer connection 30

Power supply fuse holder cage screw

terminal

FU - FUA

- FUB

0,5 … 0,8

Power supply circuit breaker cage screw

terminal

QF, QF1 2

Circuit breaker cage screw terminal option

284

QFA 2

Socket cage screw terminal option 284 PC 1,2

Compressor fuse holder cage screw

terminal

FU1 --> FU8 3,5

Compressor contactor cage screw terminal

Size 170R to 550 - Check

KM1-->KM8 1,7

Compressor contactor cage screw terminal

Size 170R to 550 - Power

KM1-->KM8 5

Compressor circuit breakers cage screw

terminal Size 610R to 950R

QM1-->QM8 5

Compressor contactor cage screw terminal

Size 610R to 950R - Check

KM1-->KM8 1,2

Compressor contactor cage screw terminal

Size 610R to 950R - Power

KM1-->KM8 9

Screw terminal, fan circuit breakers

QM11--

>QM62

High 1,7 /

Low 1,3

Variable drive cage screw terminal 1,5 kW,

2,2 kW, 4 kW

GS11 -->

GS22

1,3

Variable drive cage screw terminal 7,5 kW,

11 kW

GS11 -->

GS22

2,5

Variable drive cage screw terminal 15 kW,

18 kW

GS11 -->

GS22

4,5

M6 screw, customer connection (30RB-

RBP and 30RQ-RQP ≤ 170R)

QS101 8

M8 screw, customer connection (180R ≤

30RB-RBP and 30RQ-RQP ≤ 270R)

QS101 15

M10 screw, customer connection (310R ≤

30RQ-RQP ≤ 520R)

QS101 50

M10 screw, customer connection (310R ≤

30RB-RBP ≤ 720R)

QS101 50

M12 screw, customer connection (from

30RB-RBP770R to 30RB-RBP950R)

QS101 75

13 - STANDARD MAINTENANCE

96

Loading...

Loading...