Do you have a question about the CKD RAPIFLOW FSM3 Series and is the answer not in the manual?

| Brand | CKD |

|---|---|

| Model | RAPIFLOW FSM3 Series |

| Category | Accessories |

| Language | English |

Five types of gases can be measured with just one unit.

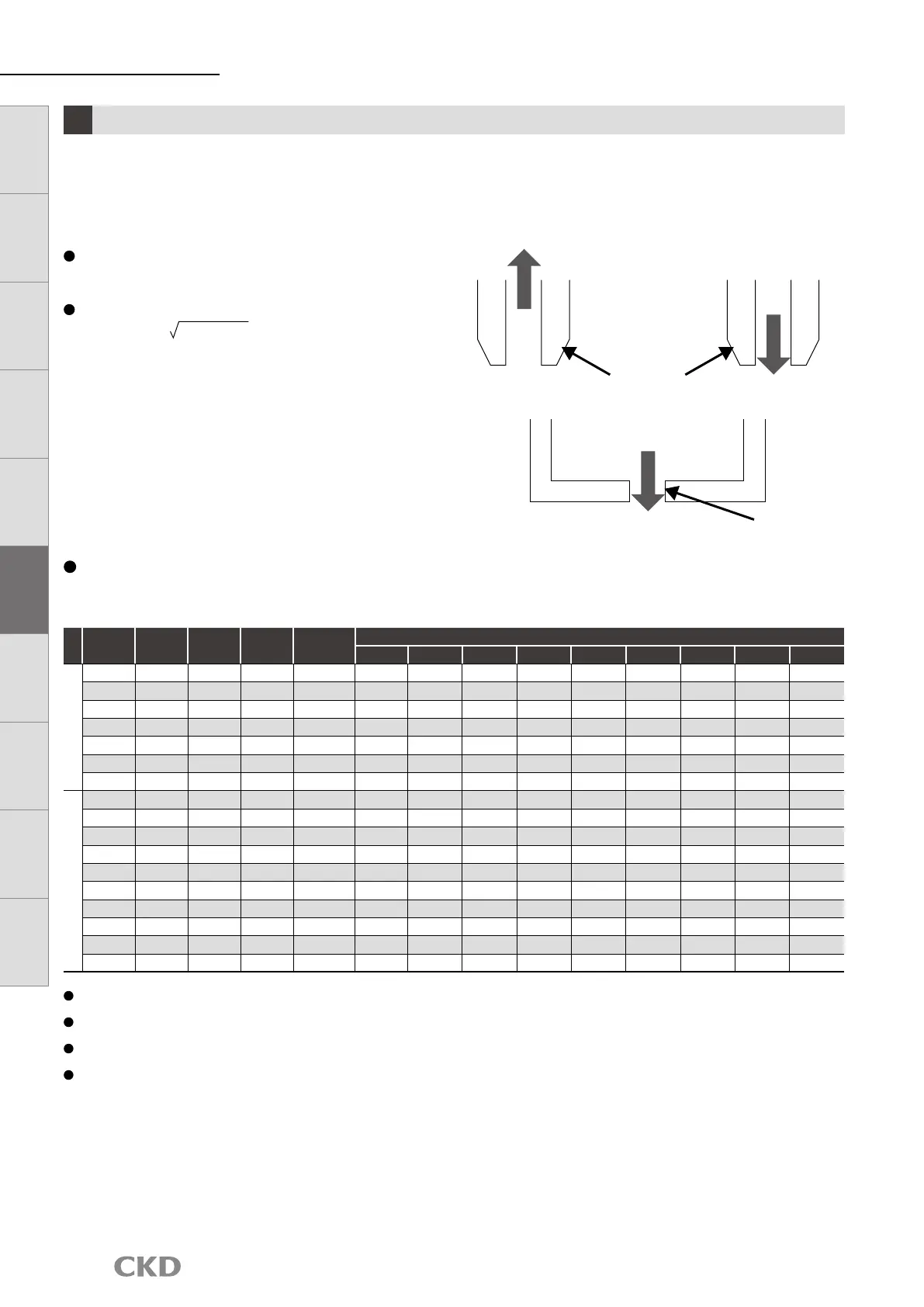

Covers pressure loss reduction, high precision, and bi-directional measurement.

Availability of clean-room compliant models for specific applications.

Benefits and features of IO-Link communication for data transfer.

Features like rotatable display, various fittings, easy mounting, and space saving.

Using the sensor for leak detection in piping systems.

Monitoring air consumption of facilities using air devices.

Controlling flow rate during coating with electro-pneumatic regulators.

Detecting electronic parts suction using flow rate.

Maintaining flow rate for shielding gases in arc welding.

Controlling gold wire tension for electronic part installation.

Overview and specifications for LCD display variants.

Overview and specifications for Bar display variants.

Overview and specifications for IO-Link variants.

Explains model number codes, options, and selection precautions.

Physical dimensions for the FSM2 separated display unit.

Details of internal components for FSM3-B models 005 to 500.

Details of internal components for FSM3-L models 500 to 201.

Details of internal components for FSM3-L models 501 and 102.

Internal structure details for the FSM2-D separate display.

Wiring diagram for LCD display with NPN output.

Wiring diagram for LCD display with PNP output.

Wiring diagram for LCD display with NPN output and copy function.

Wiring diagram for LCD display with PNP output and copy function.

Circuit diagram for using the copy function with LCD display.

Wiring diagram for bar display and connection.

Guide for connecting the separate display to the bar display.

Performance curves showing analog output behavior.

Troubleshooting guide for error codes displayed on the LCD.

Details on configuration settings available in SET mode.

Functions available for device maintenance.

Troubleshooting guide for error codes displayed on the bar display.

Details on IO-Link protocol version, bit rate, and data format.

Data mapping table for IO-Link process data.

Functions for checking SET mode settings.

Essential safety information for handling, usage, and maintenance.

Details on warranty terms, scope, and exclusions.

Guidelines for suitable fluids, operating environments, and temperature.

Notes on flow rate units, overflow handling, and pressure difference.

Specific warnings and precautions for needle valve integrated models.

Precautions for using the product in suction applications.

Guidelines and precautions for proper piping installation.

Guidelines and precautions for proper mounting.

Precautions regarding wiring connections and adjustments.

Guidelines for product usage, maintenance, and troubleshooting.

Specific cautions for the FSM2-D separated display unit.

Detailed guide for mounting and adjusting the product.

Overview of the FSM3 series flow rate sensors and their applications.

Information on the related FCM series flow rate controllers.

Information on related inline clean filters for various applications.

Information on the EVS2 series compact electro pneumatic regulators.

Information on the EVR series high precision electro pneumatic regulators.

Information on the PPX series digital pressure sensors.

Precautions for correct piping installation and thread sealing.

Precautions for correct mounting, including temperature effects.

Precautions for wiring, surge protection, and adjustments.

Precautions for product usage, maintenance, and preventing damage.

Guide for mounting, installing, and adjusting the FSM2-D separated display.